Preparation method of flexible sensor for monitoring respiration

A flexible sensor and flexible technology, which can be used in sensors, evaluation of respiratory organs, diagnostic recording/measurement, etc., can solve the problems of high cost, complex sensor manufacturing process and large volume, and achieve low manufacturing cost, thin overall thickness and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The technical scheme that the present invention solves the problems of the technologies described above is as follows:

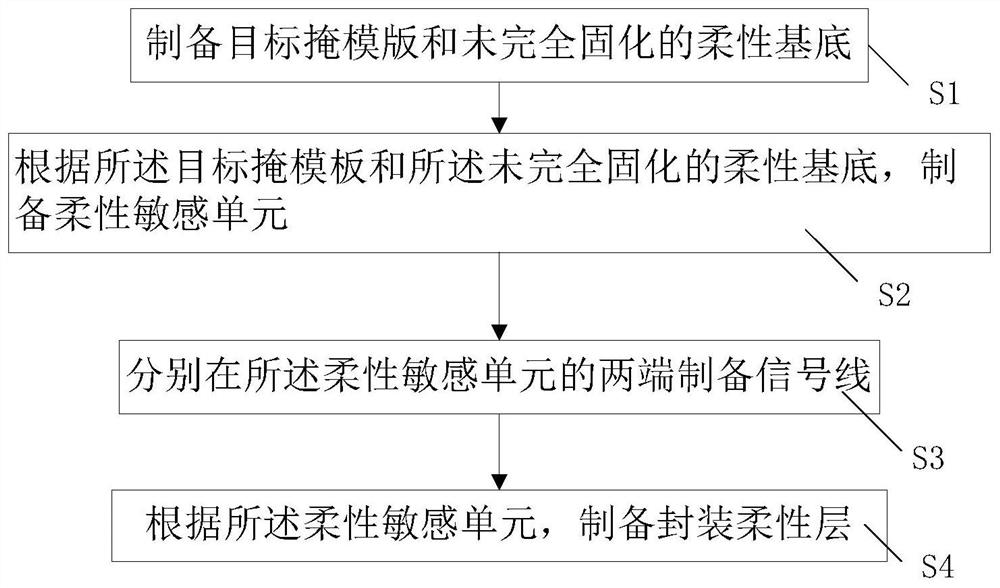

[0044] The invention provides a method for preparing a flexible sensor for monitoring respiration, referring to figure 1 Shown, described flexible sensor preparation method comprises:

[0045] S1: preparing a target mask plate and an incompletely cured flexible substrate 1;

[0046] S2: Prepare a flexible sensitive unit 2 according to the target mask and the incompletely cured flexible substrate 1;

[0047] S3: preparing signal lines 3 at both ends of the flexible sensitive unit 2;

[0048] S4: According to the flexible sensitive unit 2, prepare the packaging flexible layer 4.

[0049] The present invention has the following beneficial effects:

[0050] 1. The flexible sensor produced by the present invention has the advantages of good tensile performance, strong wearability, low production cost, simple process, high stability, small volume, thin ...

Embodiment 2

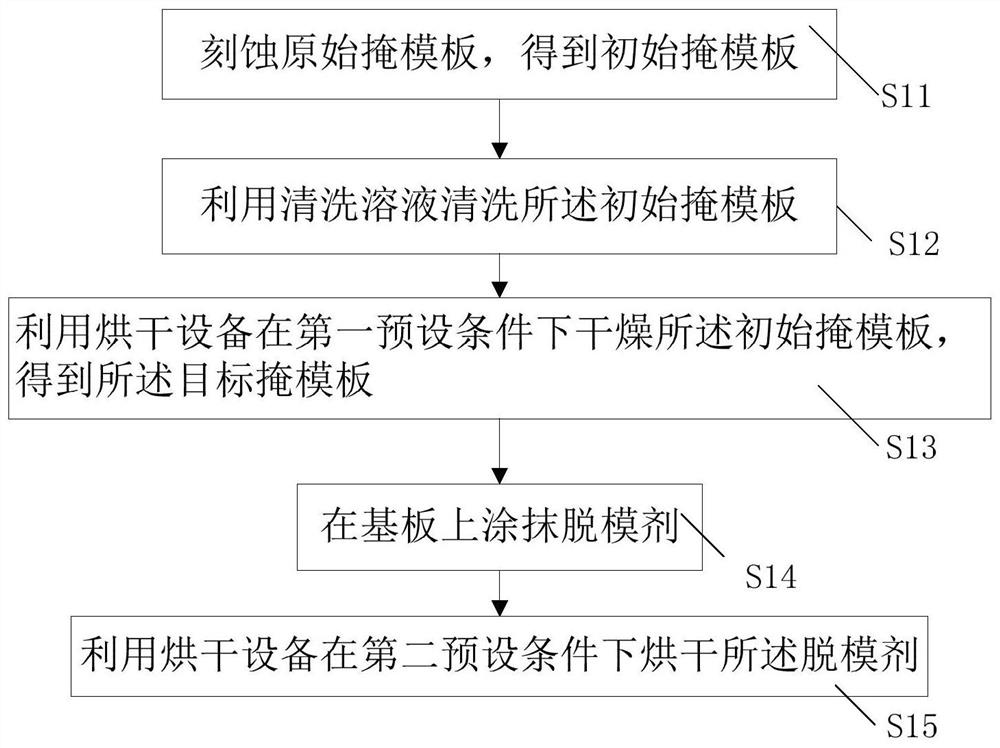

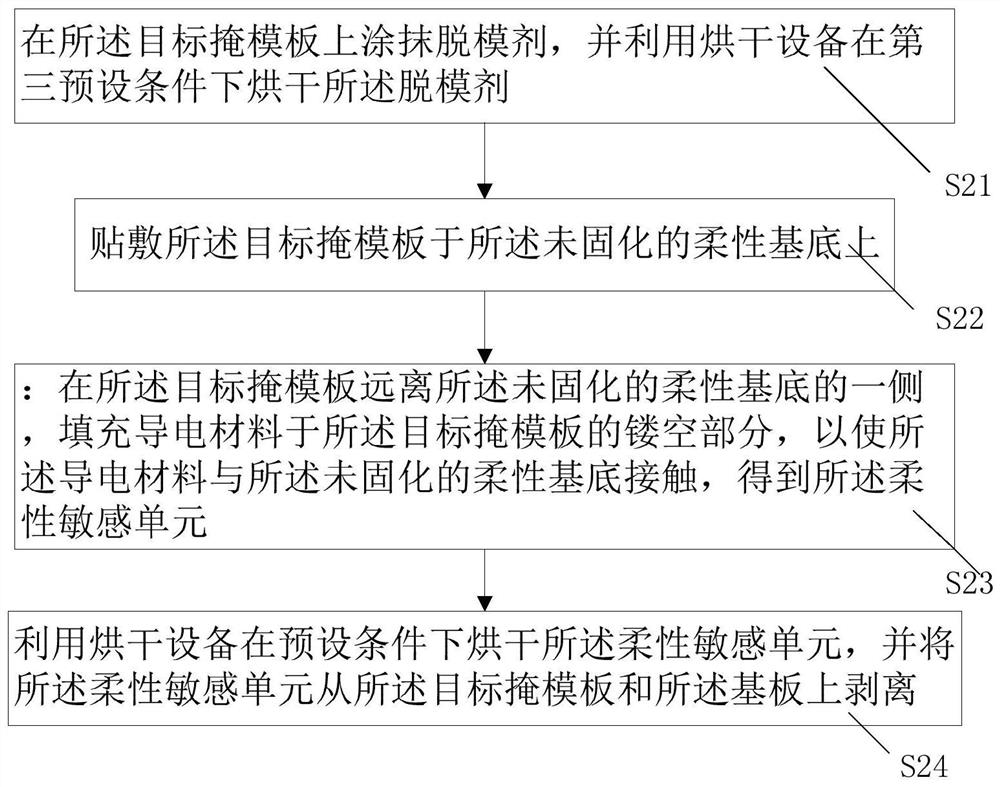

[0081] A method for preparing a flexible sensor for monitoring breathing, comprising the following steps: making a mask plate: a cutting machine cuts a required shape on an aluminum plate to prepare a mask plate, cleans it with deionized water, and dries it at 80° C. for two hours. Preparation of flexible substrate 1: spray release agent evenly on the mask plate and aluminum substrate, then heat in an oven at 60-100°C for 1-2 hours, and then spin-coat the flexible polymer solution onto the smooth substrate. Making the flexible sensitive unit 2: attach the aluminum reticle on the uncured PDMS solution, fill the CNTs into the groove of the reticle, and then heat in an oven at 80°C for 2 hours, and finally remove the flexible sensitive unit 2 from the reticle and peel off the substrate. Lead wires: use conductive silver paste or conductive carbon oil to connect copper wires to both ends of the sensitive unit, and heat at 120°C for 1-2 hours to cure the conductive silver paste or ...

Embodiment 3

[0083] Referring to Example 1, the flexible polymer can also be replaced by polyimide, polydimethylsiloxane, polyurethane; the conductive material can also be replaced by single-walled carbon nanotubes, multi-walled carbon nanotubes, Industrialized carbon nanotubes, graphene, carbon black, carbon fibers, metal nanowires; the physical or chemical etching method can also be replaced by laser etching, acid-base solution etching. The substrate can also be replaced with cardboard, glass plate, or plastic plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com