High-activity metallurgical slag composite micro powder and preparation method thereof

A metallurgical slag, high activity technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor stability, poor performance, coarse fineness, etc., achieve good stability and improve physical properties , the effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

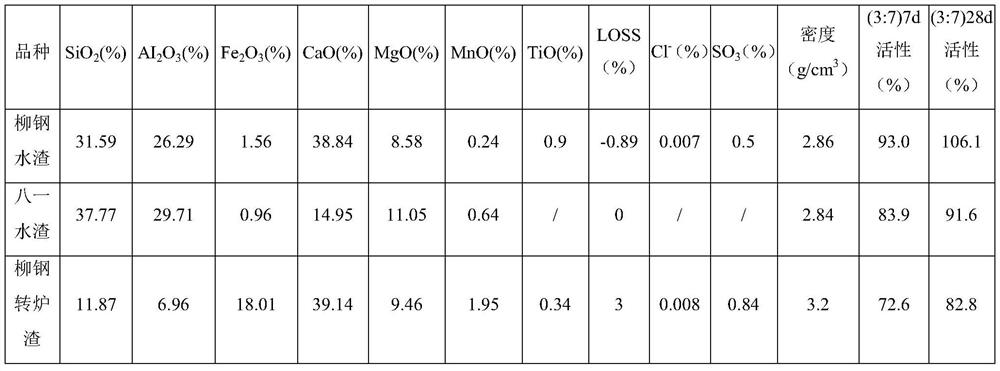

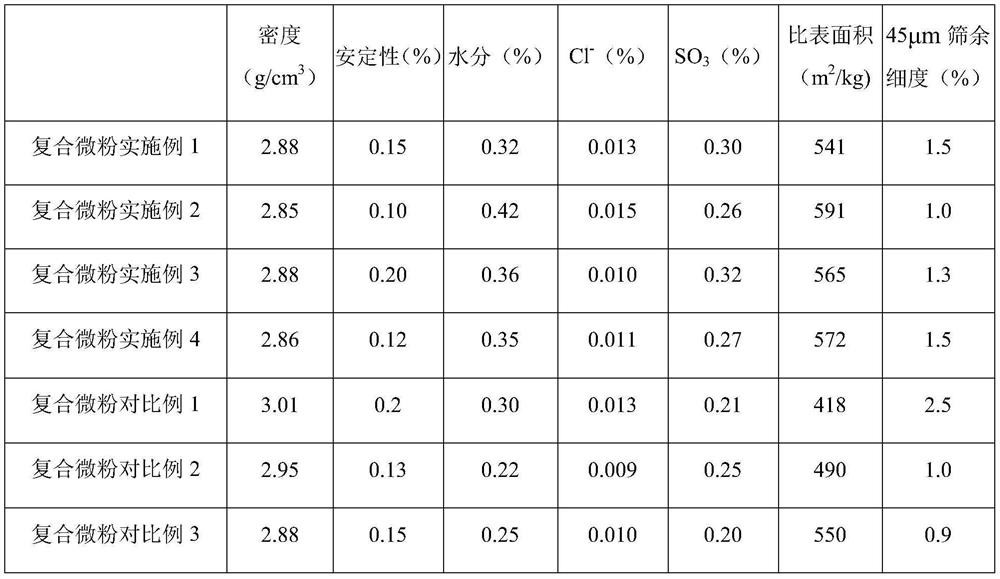

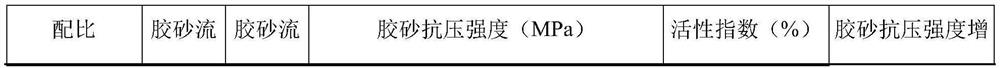

Examples

Embodiment 1

[0032] A method for preparing the above-mentioned high-activity metallurgical slag composite micropowder, comprising the following steps:

[0033] (1) Pulverized coal preparation: crush the bulk coal into pulverized coal below 5mm;

[0034] (2) Material drying: transport the pulverized coal to the fluidized fluidized furnace for combustion. The temperature of the hot air provided by the fluidized fluidized furnace is 250°C. The heat generated by the pulverized coal in the fluidized fluidized furnace dries Liugang slag, Bayi slag and converter slag;

[0035] (3) Raw material grinding: in terms of weight percentage, the main material and additive are mixed according to a certain weight ratio. Powder activator, the addition of mineral powder activator is 0.1% of the weight of the main material, and the mineral powder activator consists of diethylene glycol, triethanolamine, polycarboxylate water reducer and calcium hydroxide according to the mass ratio of 3:4:2: 1 Mixed composit...

Embodiment 2

[0037] A method for preparing the above-mentioned high-activity metallurgical slag composite micropowder, comprising the following steps:

[0038] (1) Pulverized coal preparation: crush the bulk coal into pulverized coal below 5mm;

[0039] (2) Material drying: transport the pulverized coal to the fluidized fluidized furnace for combustion. The temperature of the hot air provided by the fluidized fluidized furnace is 255°C. The heat generated by the pulverized coal in the fluidized fluidized furnace dries Liugang slag, Bayi slag and converter slag;

[0040] (3) Raw material grinding: in terms of weight percentage, the main material and additive are mixed according to a certain weight ratio. Powder activator, the addition of mineral powder activator is 0.08% of the weight of the main material, and the mineral powder activator consists of diethylene glycol, triethanolamine, polycarboxylate water reducer and calcium hydroxide according to the mass ratio of 2:5:1: 1 Mixing compos...

Embodiment 3

[0042] A method for preparing the above-mentioned high-activity metallurgical slag composite micropowder, comprising the following steps:

[0043] (1) Pulverized coal preparation: crush the bulk coal into pulverized coal below 5mm;

[0044] (2) Material drying: transport the pulverized coal to the fluidized fluidized furnace for combustion. The temperature of the hot air provided by the fluidized fluidized furnace is 260°C. The heat generated by the pulverized coal in the fluidized fluidized furnace dries Liugang slag, Bayi slag and converter slag;

[0045] (3) Raw material grinding: in terms of weight percentage, the main material and additive are mixed according to a certain weight ratio. Powder activator, the addition of mineral powder activator is 0.09% of the weight of the main material, and the mineral powder activator consists of diethylene glycol, triethanolamine, polycarboxylate water reducer and calcium hydroxide according to the mass ratio of 4:3:3: 1 Mixing compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com