Two-component polyurethane adhesive and preparation method thereof

A two-component polyurethane and prepolymer technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problem of high mechanical strength and bonding strength, medium corrosion resistance, mechanical Performance, wear resistance, poor solvent resistance, insufficient flexibility, etc., to achieve the effect of good adhesion, high weather resistance, and excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A kind of preparation method of above-mentioned two-component polyurethane glue, comprises the following steps according to above-mentioned formula ratio:

[0053] S1: preparing TPU prepolymer;

[0054] Prepare the TPU prepolymer according to the conventional method, for example: add polyisocyanate, polyether polyol or polyester polyol, and 1,4-butanediol to the reactor according to the formula, and heat to 80-100 °C while stirring. ℃, and filled with protective gas to continue heating and stirring reaction for 60-120 minutes, after adding catalyst, continue to react under heating and stirring for 30-60 minutes.

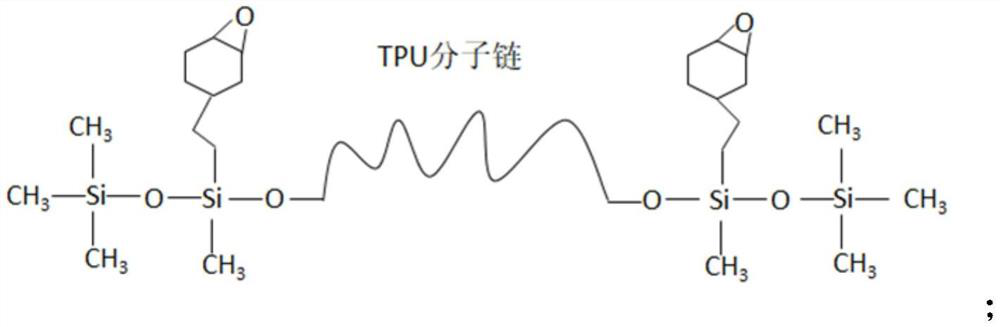

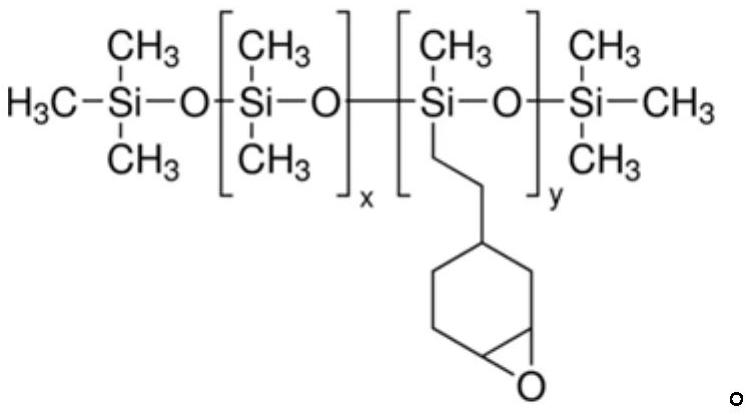

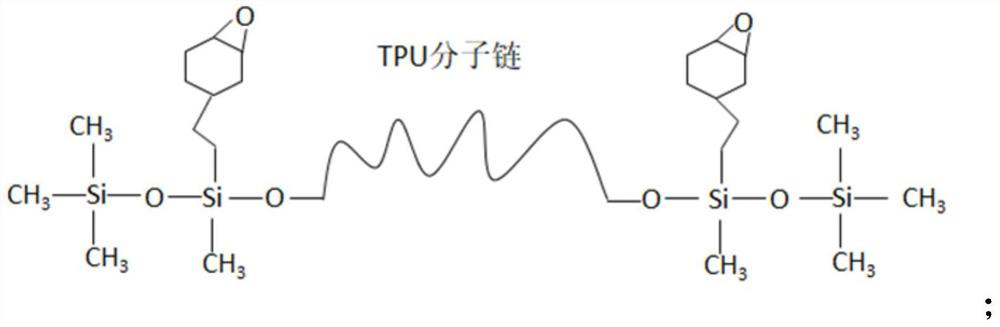

[0055] S2: Under inert gas protection and heating conditions, add epoxy-modified polysiloxane to the TPU prepolymer prepared in step S1, stir and mix until the detected NCO reaches the theoretical value, and obtain epoxy-modified polysiloxane For silicone-terminated TPU, NCO is an isocyanate group, which is an important indicator to measure the quality of pol...

Embodiment 1-2

[0071] Embodiment 1-2 preparation method is as follows:

[0072] S1: Preparation of aromatic polyether polyurethane prepolymer:

[0073] Polyisocyanate (MDI), polyether polyol (PTMEG650), and 1,4-butanediol were weighed according to the formula and added to the reactor respectively, heated to 95°C while stirring, and filled with nitrogen to continue heating and stirring for 120 minutes. After adding the catalyst, continue to react under heating and stirring for 60min.

[0074] S2: Preparation of epoxy polysiloxane-terminated polyurethane prepolymer:

[0075] Under nitrogen protection and heating at 85°C, add epoxy-modified polysiloxane to the aromatic polyether polyurethane prepolymer prepared in step (1) while stirring and mixing, and continue stirring until detection NCO reaches the theoretical value, thereby preparing epoxy-siloxane-terminated TPU;

[0076] S3: Under vacuum conditions, under the condition of stirring and mixing, according to the formula, the epoxy-siloxa...

Embodiment 3-4

[0098] Embodiment 3-4 preparation method:

[0099] S1: Preparation of aromatic polyester polyurethane prepolymer

[0100] Polyisocyanate (MDI), polyester polyol (PCL1000), and 1,4-butanediol were weighed according to the formula and added to the reactor respectively, heated to 95°C while stirring, and filled with nitrogen to continue heating and stirring for 120 minutes. After adding the catalyst, continue to react under heating and stirring for 60min.

[0101] S2: Preparation of epoxy polysiloxane-terminated polyurethane prepolymer: under the condition of nitrogen protection and heating at 85 ° C, the aromatic polyether polyurethane prepolymer prepared in step (1) is prepared under the condition of stirring and mixing Add epoxy-modified polysiloxane to the body, and continue to stir until the detected NCO reaches the theoretical value, thereby preparing epoxy-siloxane-terminated TPU;

[0102] S3: Under vacuum conditions, under the condition of stirring and mixing, according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com