Production method of mesophase pitch and production system thereof

A technology of mesophase pitch and production method, which is applied in the direction of chemically processing tar pitch/petroleum pitch/natural pitch, etc., can solve the problem of affecting the spinnable carbon fiber performance of mesophase pitch, the combination of additives and raw materials cannot be determined, and the impact of intermediate The homogeneity and quality of phase pitch can be prevented from increasing too fast, reducing the condensation reaction rate, and improving thermal stability and rheology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

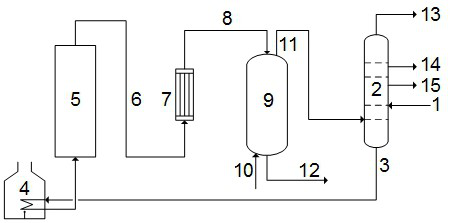

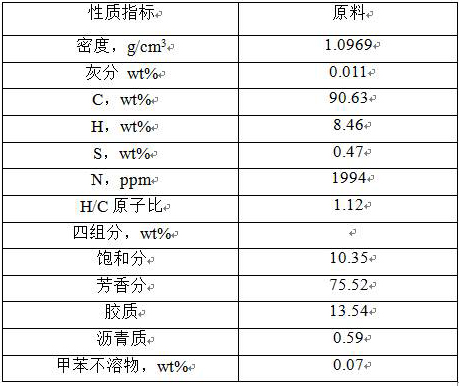

[0054] use figure 1 In the production system shown, the reaction unit A includes a reactor, the cooling rate of the quenching device is 180°C / S, the properties of raw materials are shown in Table 1, the operating conditions are shown in Table 2, and the reaction results are shown in Table 3.

Embodiment 2

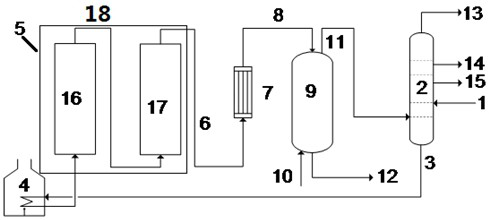

[0056] use figure 2 In the production system shown, the reaction unit A includes two reactors, namely a first reactor 16 and a second reactor 17 , and the reaction effluent 18 of the first reactor enters the second reactor 17 . The cooling rate of the quenching device is 180° C. / S. The properties of raw materials are shown in Table 1, the operating conditions are shown in Table 2, and the reaction results are shown in Table 3.

Embodiment 3

[0058] use figure 2 In the production system shown, compared with Example 2, the operating conditions are slightly adjusted. The cooling rate of the quenching device is 150° C. / S. The properties of the raw materials are shown in Table 1, the operating conditions are shown in Table 2, and the reaction results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com