Oil reservoir injection-production optimization method and device, storage medium and electronic equipment

An optimization method and technology for oil reservoir development, applied in design optimization/simulation, production of fluids, earthwork drilling, etc., to achieve the effect of improving accuracy, improving recovery potential, and optimizing technical policies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

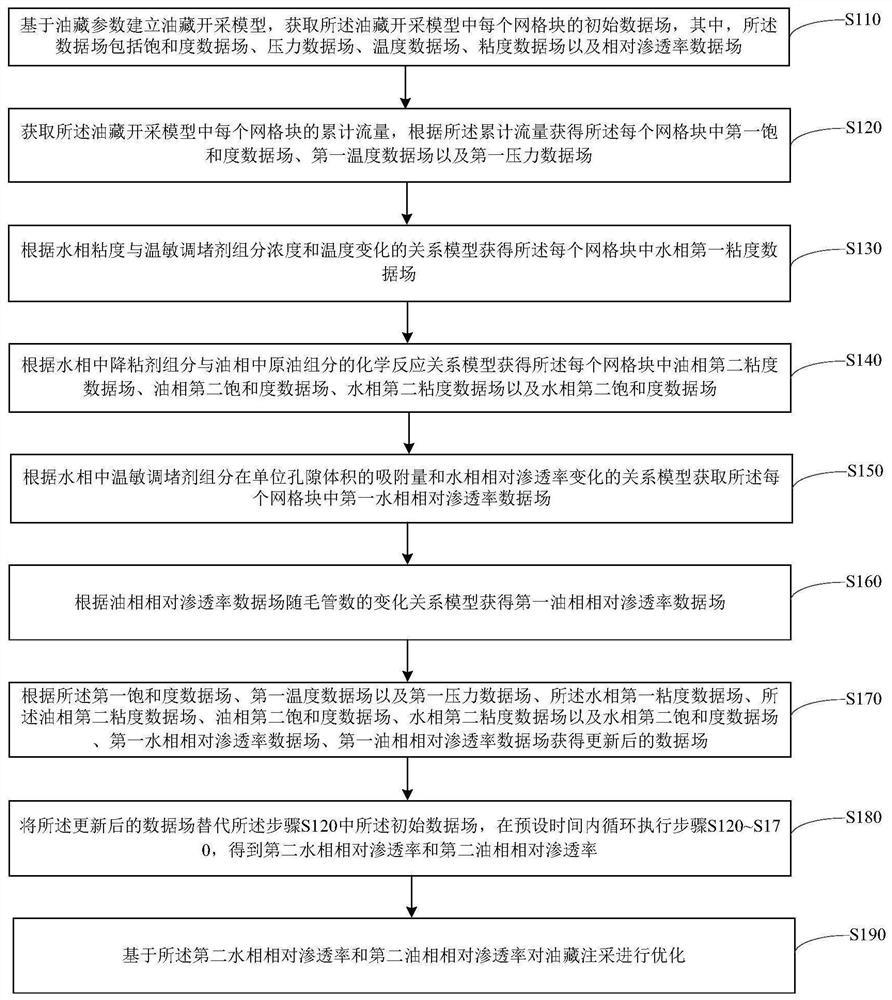

[0076] figure 1 A schematic flow chart of a reservoir injection-production optimization method provided in the embodiment of this application, as shown in figure 1 As shown, this method includes:

[0077] Step S110: Establish a reservoir production model based on reservoir parameters, and obtain the initial data field of each grid block in the reservoir production model, wherein the data field includes saturation data field, pressure data field, temperature Data field, viscosity data field and relative permeability data field;

[0078] Step S120: Obtain the cumulative flow rate of each grid block in the reservoir production model, and obtain the first saturation data field, first temperature data field, and first pressure in each grid block according to the cumulative flow rate data field;

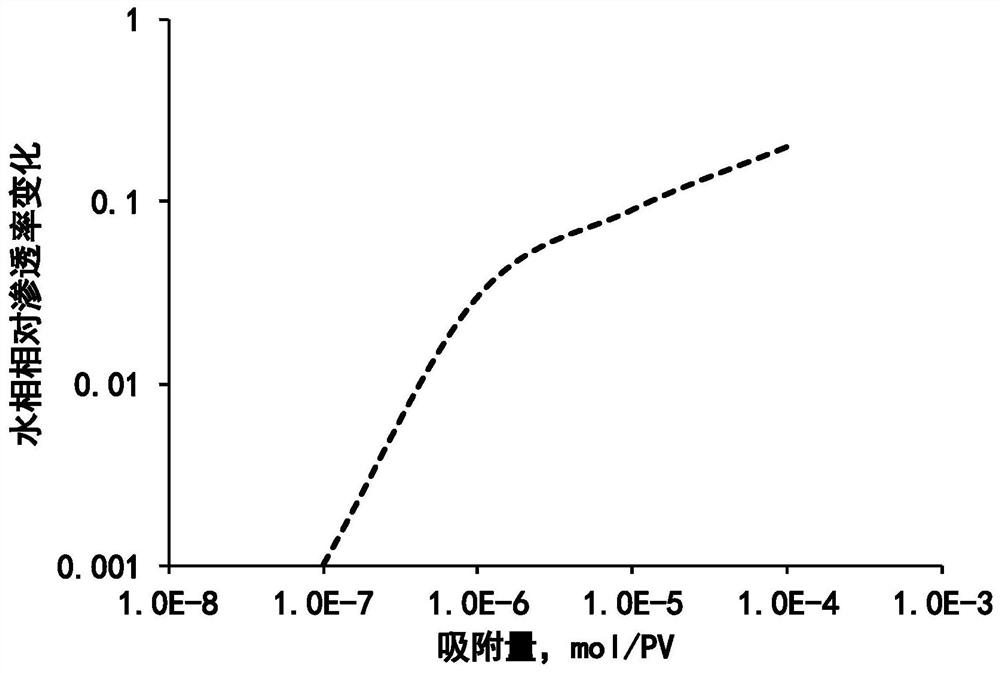

[0079] Step S130: Obtain the first viscosity data field of the water phase in each grid block according to the relationship model between the viscosity of the water phase and the concen...

Embodiment 2

[0171] In the oil reservoir, the temperature-sensitive composite flood control system is designed and constructed according to the heterogeneous characteristics of the reservoir and the distribution law of the remaining oil. It is a new type of composite oil displacement system. The water-soluble viscosity reducer is combined in a certain proportion in the form of slug, and has the functions of plugging control in the middle and deep parts and emulsification and viscosity reduction for oil displacement. A large number of laboratory experimental research data show that the oil displacement technology based on the temperature-sensitive compound control and flooding system can significantly expand the sweep and greatly improve the oil recovery factor.

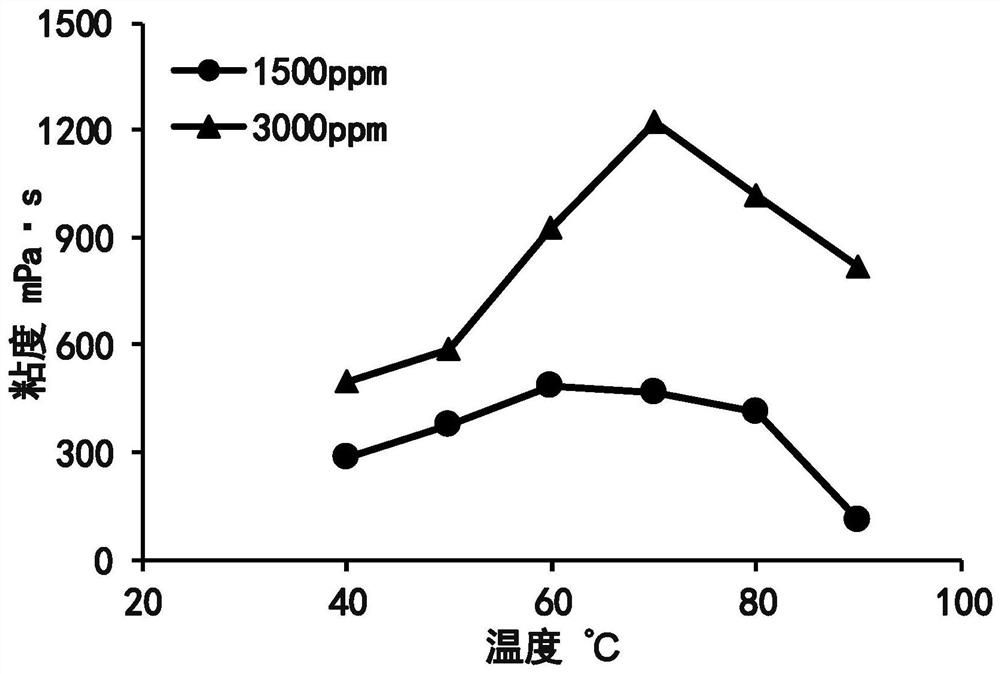

[0172] Among them, the temperature-sensitive viscoelastic polymer blocking agent is a multi-component copolymer with temperature-sensitive properties prepared by a free radical aqueous solution polymerization method on the basis of...

Embodiment 3

[0192] Image 6 The connection block diagram of a reservoir injection-production optimization device 200 provided in the embodiment of the present application is as follows: Image 6 The illustrated apparatus 200 includes:

[0193] A model building module 201, the model building module 201 is configured to build a reservoir production model based on reservoir parameters, and obtain an initial data field for each of the grid blocks in the reservoir production model, wherein the data field Including saturation data field, pressure data field, temperature data field, viscosity data field and relative permeability data field;

[0194] The first data acquisition module 202, the first data acquisition module 202 is configured to acquire the cumulative flow of each grid block in the oil reservoir production model, and obtain the first data in each grid block according to the cumulative flow. a saturation data field, a first temperature data field and a first pressure data field;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com