Antimony-based photocathode Sb2S3/Sb2O3 heterojunction structure and preparation method thereof

A heterojunction, antimony-based optical technology, applied in final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve photogenerated carrier separation and transmission speed limitations, reduce carrier separation efficiency, and limit energy Conversion efficiency and other issues, to achieve good electronic conductivity, good co-solubility, and improve charge transfer efficiency and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

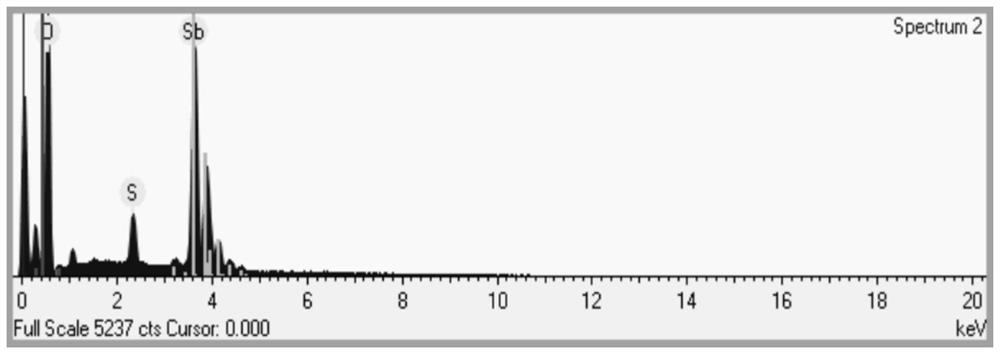

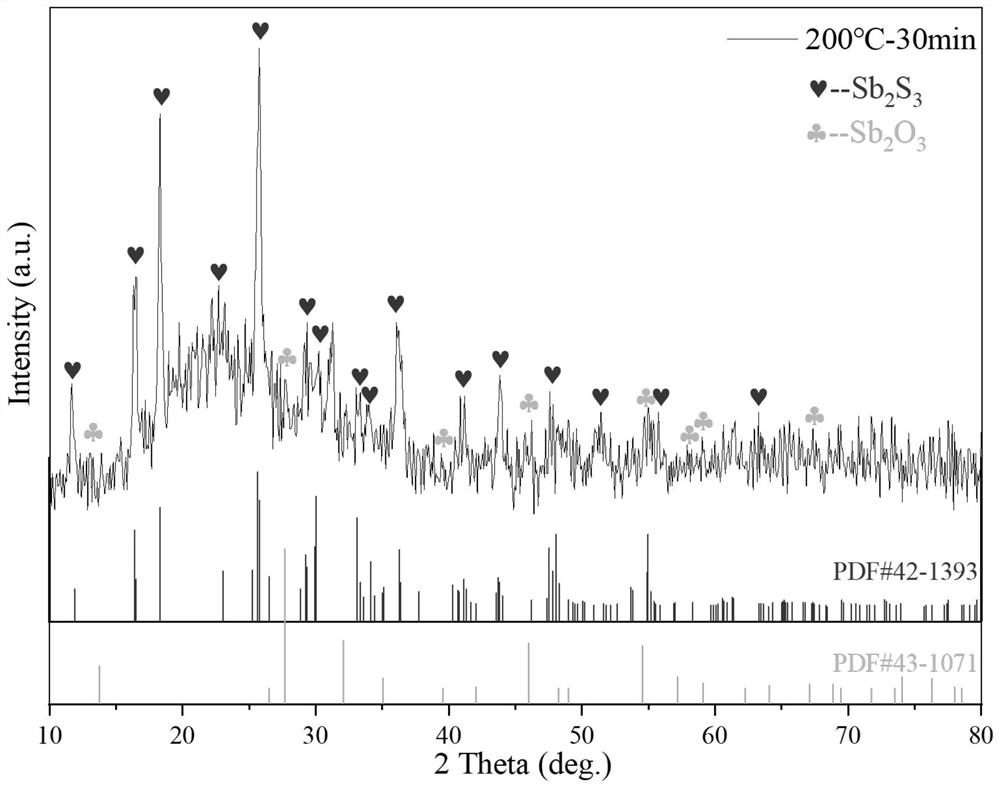

[0031] Embodiment 1: A kind of antimony-based photocathode Sb 2 S 3 / Sb 2 o 3 heterojunction structure, consisting of p-type Sb 2 S 3 Thin film bottom layer, Sb 2 S 3 / Sb 2 o 3 buffer layer and n-type Sb 2 o 3 Composition of the top layer of the film;

[0032] Antimony-based photocathode Sb 2 S 3 / Sb 2 o 3 The preparation method of the heterojunction structure, the preparation of the metal Sb film adopts the vapor phase deposition method, the Sb source is selected from high-purity metal Sb powder, and the substrate is selected from ITO; Sb 2 S 3 The preparation adopts the heating method, and the S source is selected from solid sublimated sulfur; Sb 2 S 3 / Sb 2 o 3 Heterojunction is prepared by heating method; the specific steps are as follows:

[0033] (1) Sputtering Sb on the substrate to obtain Sb film: 5g high-purity metal antimony powder is packed in a crucible, placed in a tube furnace, and the cleaned ITO substrate is placed above the antimony powder ...

Embodiment 2

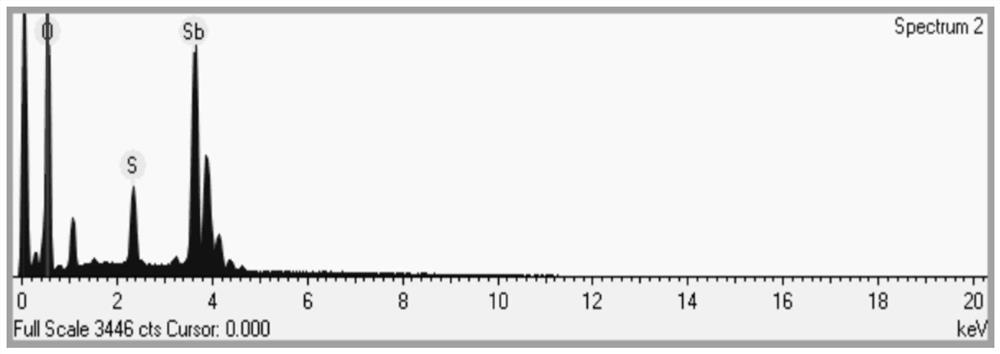

[0037] Embodiment 2: A kind of antimony-based photocathode Sb 2 S 3 / Sb 2 o 3 heterojunction structure, consisting of p-type Sb 2 S 3 Thin film bottom layer, Sb 2 S 3 / Sb 2 o 3 buffer layer and n-type Sb 2 o 3 Composition of the top layer of the film;

[0038] Antimony-based photocathode Sb 2 S 3 / Sb 2 o 3 The preparation method of the heterojunction structure, the preparation of the metal Sb film adopts the magnetron sputtering method, the Sb source is selected from high-purity metal Sb powder, and the substrate is selected from ITO; Sb 2 S 3 The preparation adopts the PECVD method, and the S source is selected from H 2 S; Sb 2 S 3 / Sb 2 o 3 The heterojunction is prepared by PECVD method; the specific steps are as follows:

[0039] (1) Sputtering Sb on the substrate to obtain Sb thin film: place the high-purity metal antimony target (≥99.99%) on the metal target seat in the magnetron sputtering furnace cavity; after cleaning, the ITO is inverted on the ma...

Embodiment 3

[0043] Embodiment 3: A kind of antimony-based photocathode Sb 2 S 3 / Sb 2 o 3 heterojunction structure, consisting of p-type Sb 2 S 3 Thin film bottom layer, Sb 2 S 3 / Sb 2 o 3 buffer layer and n-type Sb 2 o 3 Composition of the top layer of the film;

[0044] Antimony-based photocathode Sb 2 S 3 / Sb 2 o 3 The preparation method of the heterojunction structure, the preparation of the metal Sb film adopts the vapor phase deposition method, the Sb source is selected from high-purity metal Sb powder, and the substrate is selected from FTO; Sb 2 S 3 The preparation adopts the plasma method, and the S source is selected from solid sublimated sulfur; Sb 2 S 3 / Sb 2 o 3 The heterojunction is prepared by PECVD method; the specific steps are as follows:

[0045] (1) Sputtering Sb on the substrate to obtain Sb film: 5g high-purity metal antimony powder is packed in a crucible, placed in a tube furnace, and the cleaned ITO substrate is placed above the antimony powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com