Graphene and heat pump coupled heating and cooling device for power battery pack

A power battery pack and graphene technology, which is applied to battery pack parts, secondary batteries, circuits, etc., can solve the problems of low warm-up efficiency and low energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

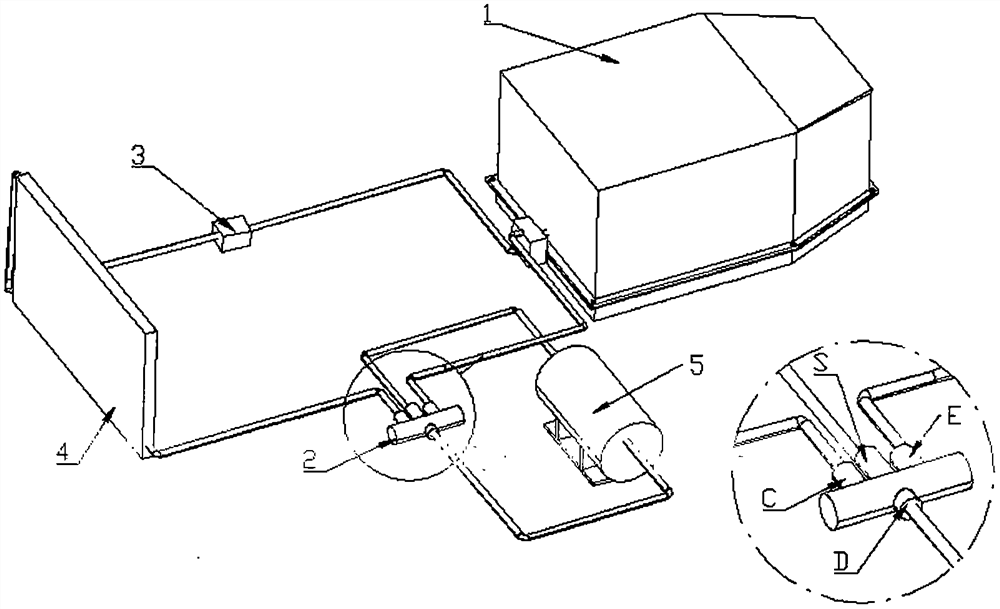

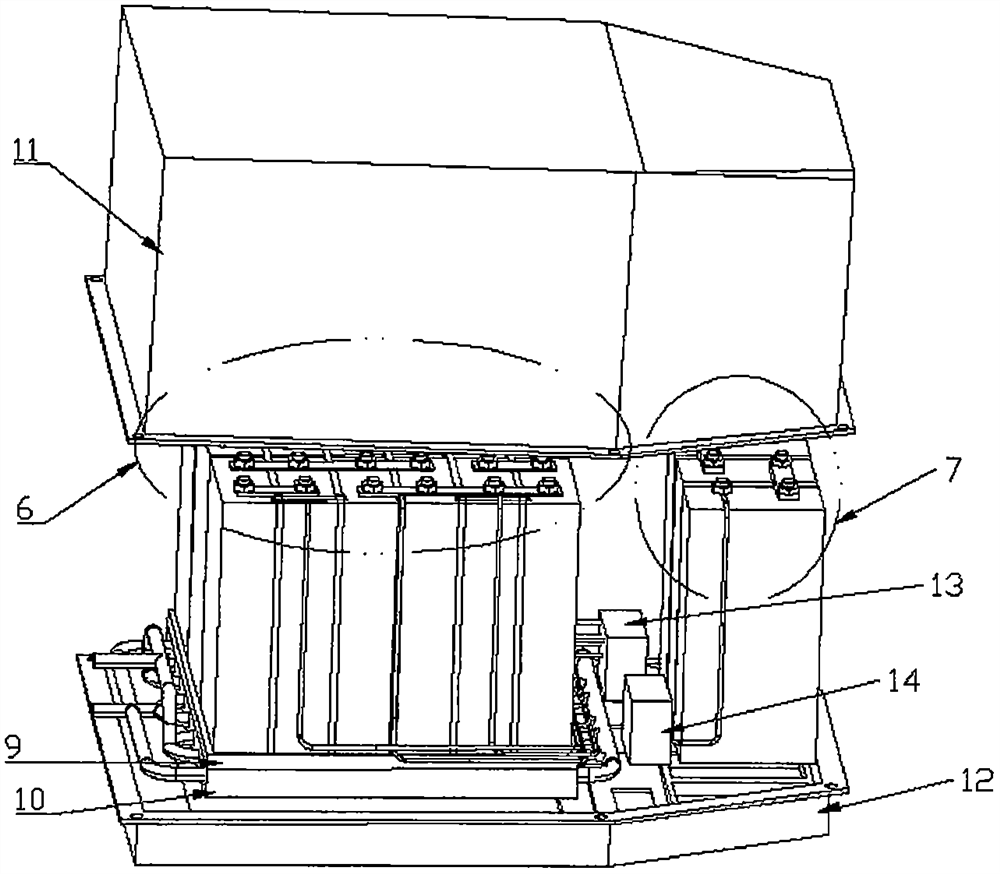

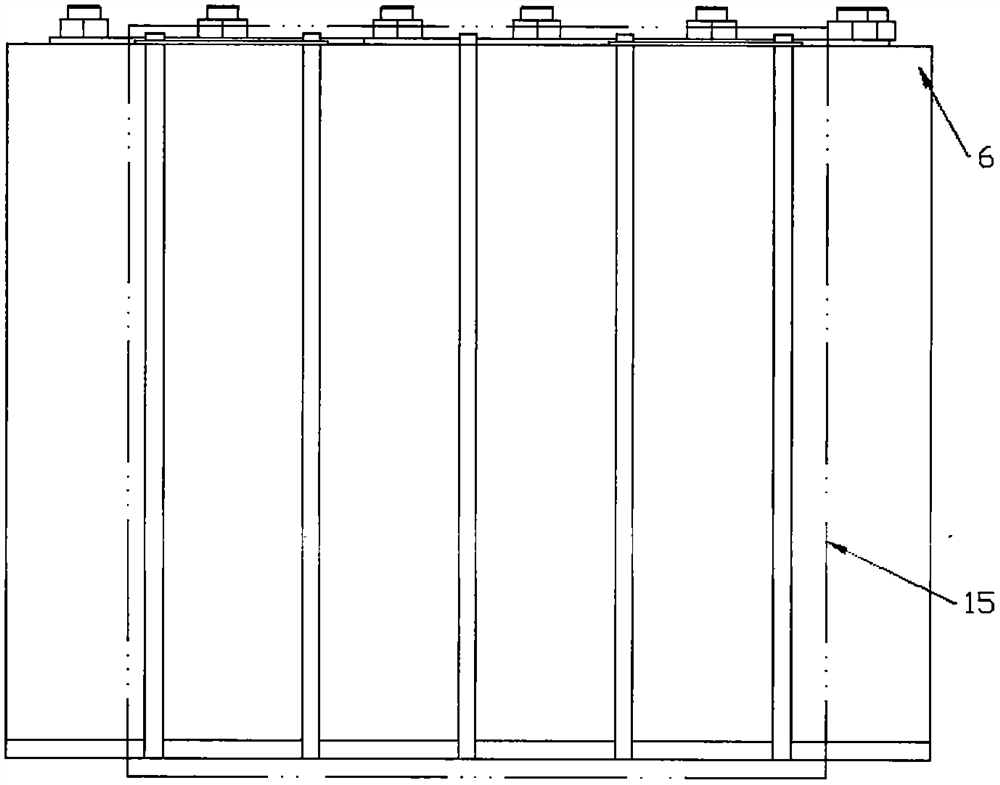

Method used

Image

Examples

Embodiment Construction

[0024] The graphene element of the present invention uses graphene oxide ink as a raw material, and the required shape is printed layer by layer by a 3D printer, and then the graphene is reduced through a Joule heating process.

[0025] The graphene oxide preparation method adopted by the graphene element is as follows: using graphite as a raw material, 1.5 g of graphite is added to 200 ml of sulfuric acid / H3PO4 (volume ratio 9:1) solution by using the improved Hummer method. 9 g of kmno4 was gradually added to the above solution and stirred at 250 rpm for 12 h at 50 °C. The solution was then cooled to room temperature and poured onto 400 ml ice, while 3 ml H2O2 was added to the solution while stirring. The solution was washed with 30 ml of 37% hydrochloric acid, and then centrifuged with distilled water at a speed of 8000 rpm. The upper clear solution was decanted and refilled with distilled water and centrifuged until no precipitation of AgCl was visible in the test solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com