Preparation method of small yellow croaker flavor material

A technology of small yellow croaker and flavoring ingredients, which is applied in the field of food processing, can solve the problems of difficult processing of fish waste, low hygiene and safety, and low technical content, and achieve the effects of shortening processing time, rich nutrition, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

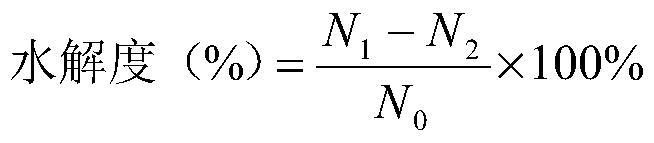

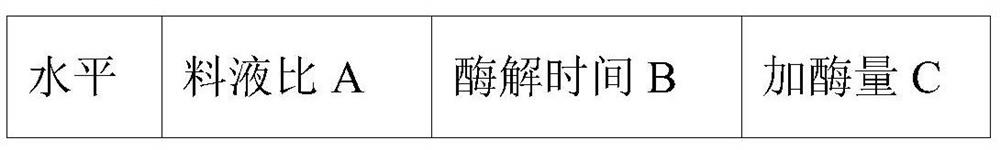

Method used

Image

Examples

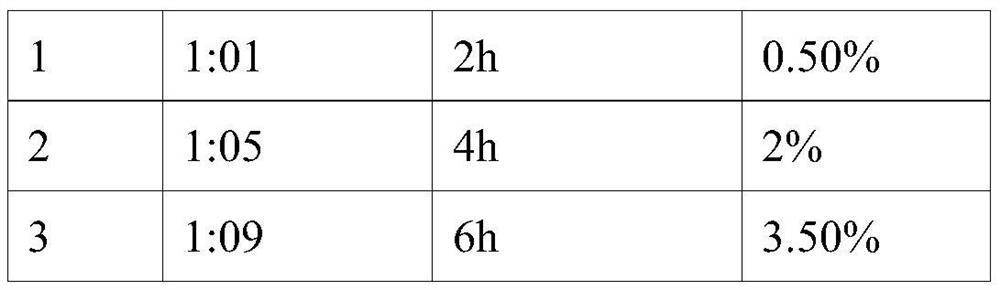

Embodiment 1

[0045] A preparation method of small yellow croaker flavoring, the specific steps are:

[0046] (1) Grinding fresh small yellow croaker leftovers after steaming and cooking for 15 minutes at a power of 2000W in a microwave oven to obtain a slurry of small yellow croaker leftovers;

[0047] (2) Adjust the ratio of the small yellow croaker leftover slurry obtained in step (1) to water to 1g:1mL, add 2% (enzyme to substrate mass ratio) papain, and enzymolyze at 65°C for 4h; then Centrifuge at 4°C and 5000rmp for 15 minutes, and the supernatant is the enzymatic hydrolysis solution of the leftovers of the small yellow croaker;

[0048] (3) Add g / 100mL yeast extract to the enzymatic hydrolysis solution of the leftovers of the small yellow croaker obtained in step (2), and treat it in a water bath at 40°C for 1 hour to remove the fishy smell, and obtain the base material of the small yellow croaker flavoring material;

[0049] (4) Add 1g / dL of salt, 1g / dL of sucrose and 3g / dL of lig...

Embodiment 2

[0053] A preparation method of small yellow croaker flavoring, the specific steps are:

[0054] (1) Grinding fresh small yellow croaker leftovers after steaming and cooking for 15 minutes at a power of 2000W in a microwave oven to obtain a slurry of small yellow croaker leftovers;

[0055] (2) adjust the slurry obtained in the step (1) to obtain the leftovers of the small yellow croaker with a water ratio of 1g: 1mL to add water and stir, add 0.5% (enzyme to substrate mass ratio) papain, at 65 ° C Enzymolysis for 2 hours; then centrifuged at 4°C and 5000rmp for 15 minutes, the supernatant was the enzymatic hydrolysis solution of the leftovers of the small yellow croaker;

[0056] (3) Add g / 100mL of yeast extract to the enzymolysis solution of the offal of the small yellow croaker obtained in step (2), and treat it in a water bath at 40°C for 1 hour to remove the fishy smell, and obtain the base material of the small yellow croaker flavoring material;

[0057] (4) Add 1g / dL of...

Embodiment 3

[0061] A preparation method of small yellow croaker flavoring, the specific steps are:

[0062] (1) Grinding fresh small yellow croaker leftovers after steaming and cooking for 15 minutes at a power of 2000W in a microwave oven to obtain a slurry of small yellow croaker leftovers;

[0063] (2) The slurry obtained in the adjustment step (1) to obtain the leftovers of the small yellow croaker is 1g:1mL to add water and stir with the ratio of water, add the papain of 3.5% (enzyme and substrate mass ratio), at 65 ℃ Enzymolysis for 6 hours; then centrifuged at 4°C and 5000rmp for 15 minutes, the supernatant was the enzymatic hydrolysis solution of the leftovers of the small yellow croaker;

[0064] (3) Add 1 g / dL of yeast extract to the enzymatic hydrolyzate of small yellow croaker flavor material obtained in step (2), and treat it in a water bath at 40°C for 1 hour to remove the fishy smell;

[0065] (4) Add 1g / dL of salt, 1g / dL of sucrose and 3g / dL of light soy sauce to the deod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com