Treatment method of high-concentration high-salt methanol organic wastewater

A technology of organic wastewater and treatment methods, applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc., can solve the problems of large amount of hazardous waste, poor treatment effect, low treatment rate, etc., and achieve low investment cost , It is not easy to coke and foam, and the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

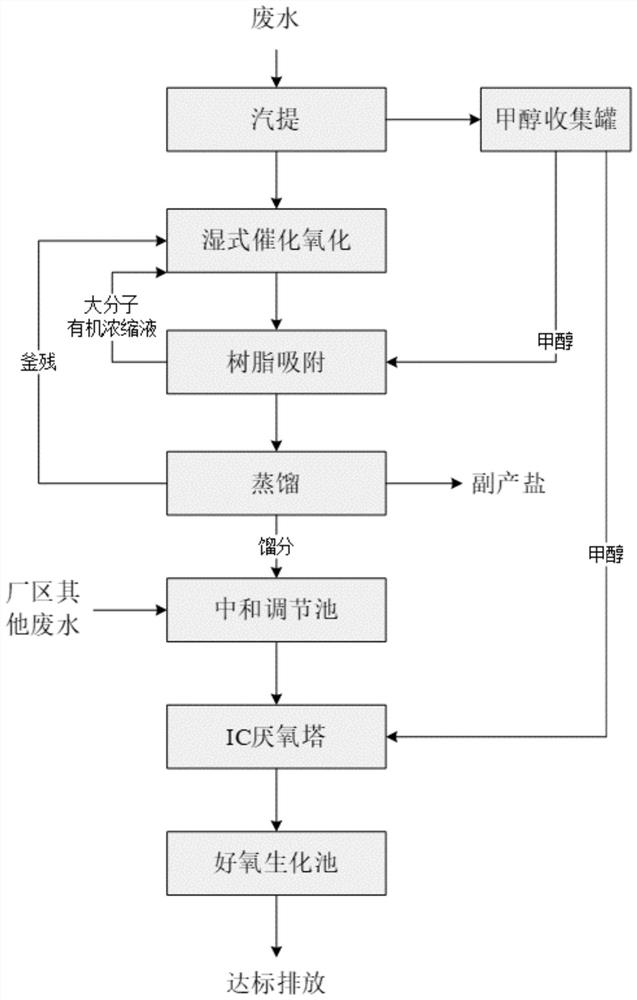

[0038] The invention provides a treatment method for high-concentration and high-salt methanol organic wastewater, the treatment process is as follows:

[0039] S100. The organic wastewater is stripped. As a specific embodiment, the organic wastewater is stripped by a stripper to obtain methanol recovery liquid and stripped water; wherein, the temperature at the bottom of the stripper is 115-125° C. , the top pressure of the tower is 20-30MPa, and the liquid level at the bottom of the tower is 40%-60%. Tanks and other storage devices, and as the resin desorption liquid in the resin adsorption process of the present invention or the carbon source in the biochemical treatment, and then reused in the process flow of the present invention; The desorption liquid generated later can also be further treated by mixing with stripped water and then performing wet catalytic oxidation, which will not generate additional pollution or be treated by other processes, and the treatment efficie...

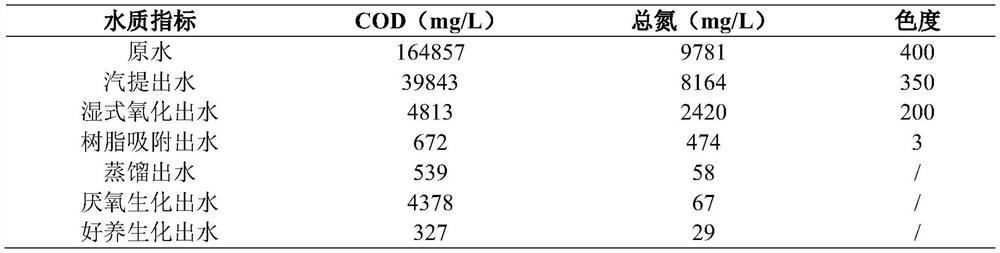

Embodiment 2

[0058] The basic content of this embodiment is the same as that of Example 1, and the difference is that in this embodiment, the organic waste water treated is the production waste water produced in the production process of azoxystrobin in a certain pesticide production enterprise in Jiangsu, and the treatment process is as follows:

[0059] S100, stripping the organic waste water, the temperature at the bottom of the stripping tower is 115°C, the pressure at the top of the tower is 20MPa, and the liquid level at the bottom of the tower is 60%;

[0060] S200. Mix the stripped water, distillation still residue and resin desorption solution to carry out wet catalytic oxidation. The reaction temperature is 150°C, the reaction pressure is 3.2MPa, and the reaction time is 2h;

[0061] S300, the wet catalytic oxidation effluent is subjected to resin adsorption to remove macromolecular organic matter, the wastewater flow rate is 20BV, the flow rate is 2.0BV / h, and the pH is 4;

[00...

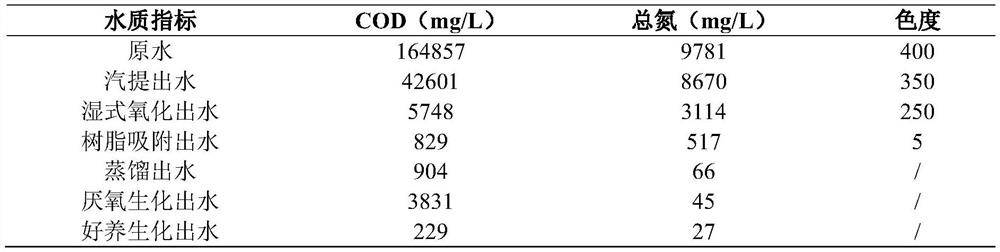

Embodiment 3

[0068] The basic content of this embodiment is the same as that of Example 1, and the difference is that in this embodiment, the organic waste water treated is the production waste water produced in the production process of azoxystrobin in a certain pesticide production enterprise in Jiangsu, and the treatment process is as follows:

[0069] S100, stripping the organic waste water, the temperature at the bottom of the stripping tower is 125°C, the pressure at the top of the tower is 30MPa, and the liquid level at the bottom of the tower is 40%;

[0070] S200, after mixing the stripped water, the residue of the distillation pot and the resin desorption liquid, perform wet catalytic oxidation, the reaction temperature is 280°C, the reaction pressure is 6.0MPa, and the reaction time is 5h;

[0071] S300, the wet catalytic oxidation effluent is subjected to resin adsorption to remove macromolecular organic matter, the wastewater flow rate is 10BV, the flow rate is 1.0BV / h, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com