Method for preparing crucible by hot-press cold-out one-step forming of regenerated graphite

A technology for regenerating graphite and crucible, applied in the field of graphite, can solve the problems of easy breakage, uneven structure, easy cracking, etc., and achieve the effect of increasing paste plasticity, increasing product strength, and preventing cracking and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

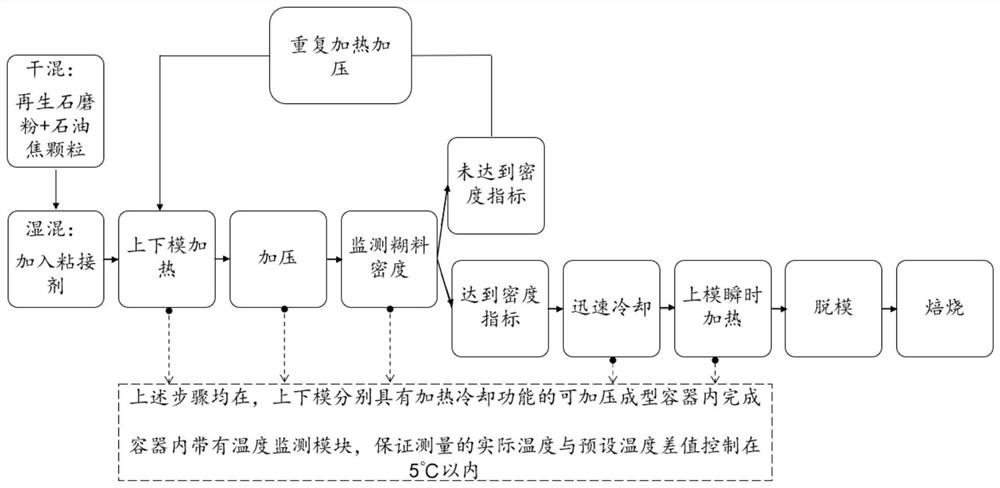

Method used

Image

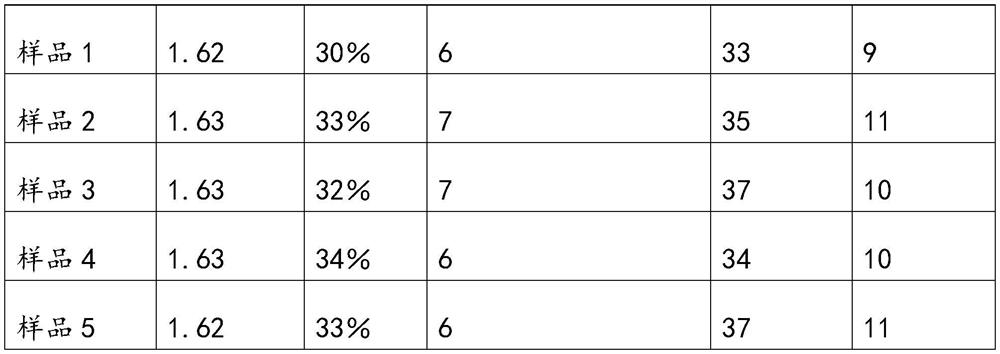

Examples

Embodiment 1

[0046] A method for preparing a crucible by hot-pressing and cooling regenerated graphite,

[0047] S1. Dry blending: make recycled graphite powder and graphitized petroleum coke particles into a dry material, pour it into a pretreated kneading pot for dry mixing, and dry mix for 40 minutes at a temperature of 120-130°C to obtain a dry blend;

[0048] Among them, the particle size of regenerated graphite powder is less than 0.5mm, accounting for 50% of the dry material mass;

[0049] The composition of graphitized petroleum coke particles is as follows: graphitized petroleum coke particles with a particle size of 0.5-4mm account for 25% of the dry material mass, and graphitized petroleum coke particles with a particle size of 4-8mm account for 25% of the dry material mass;

[0050] The pretreatment step is as follows: the kneading pot itself is externally heated by heat conduction oil, the heating temperature is 190-200°C, and the heat conduction oil is selected from L-QB300 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com