Electrolyte for lithium secondary battery, and lithium secondary battery comprising same

A technology of electrolyte solution and lithium secondary battery, which is applied in the direction of non-aqueous electrolyte storage battery, secondary battery, lithium storage battery, etc. It can solve the problems of increased resistance and reduced redox center capacity, etc., achieve excellent high-temperature durability, and improve high-temperature storage Characteristics and initial capacity, effect of suppressing collapse phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] (1) Preparation of electrolyte solution for lithium secondary battery

[0145] Mix ethylene carbonate (EC) and ethylmethyl carbonate (EMC) at a volume ratio of 3:7, and dissolve LiPF 6 and LiFSI to make LiPF 6 The concentrations of LiFSI and LiFSI were 0.7M and 0.3M, respectively, thus preparing non-aqueous organic solvents. Add 0.5g of the additive represented by Formula 1A-1, 0.1g of tetravinylsilane, 1.0g of lithium difluorophosphate, 1.0g of ethylene sulfonate, 0.5g of 1,3-propane sultone, 0.2g of LiBF 4 and 6.0 g of fluorobenzene were added to 90.7 g of a non-aqueous organic solvent to prepare an electrolyte solution for a lithium secondary battery.

[0146] (2) Preparation of lithium secondary battery

[0147] The positive electrode active material (Li(Ni 0.8 co 0.1 mn 0.1 )O 2 (NCM811): LiNi 0.6 co 0.2 mn 0.2 o 2 =70:30 weight ratio), carbon black as a conductive agent, and polyvinylidene fluoride (PVDF) as a binder are mixed in a weight ratio of 97.5:...

Embodiment 2

[0151] (1) Preparation of electrolyte solution for lithium secondary battery

[0152] Mix ethylene carbonate (EC) and ethylmethyl carbonate (EMC) at a volume ratio of 3:7, and dissolve LiPF 6 and LiFSI to make LiPF 6 The concentrations of LiFSI and LiFSI were 0.7M and 0.3M, respectively, thus preparing non-aqueous organic solvents. Add 0.2g of the additive represented by formula 1A-1, 0.1g of tetravinylsilane, 1.0g of lithium difluorophosphate, 1.0g of ethylene sulfonate, 0.5g of 1,3-propane sultone, 0.2g of LiBF 4 and 6.0 g of fluorobenzene were added to 91 g of a non-aqueous organic solvent to prepare an electrolyte solution for a lithium secondary battery.

[0153] (2) Preparation of lithium secondary battery

[0154] The positive electrode active material (Li(Ni 0.8 co 0.1 mn 0.1 )O 2 (NCM811)), carbon black as a conductive agent, and polyvinylidene fluoride (PVDF) as a binder were mixed in a weight ratio of 97.5:1:1.5, and then added to N-methyl-2-pyrrolidone as a ...

experiment example 1

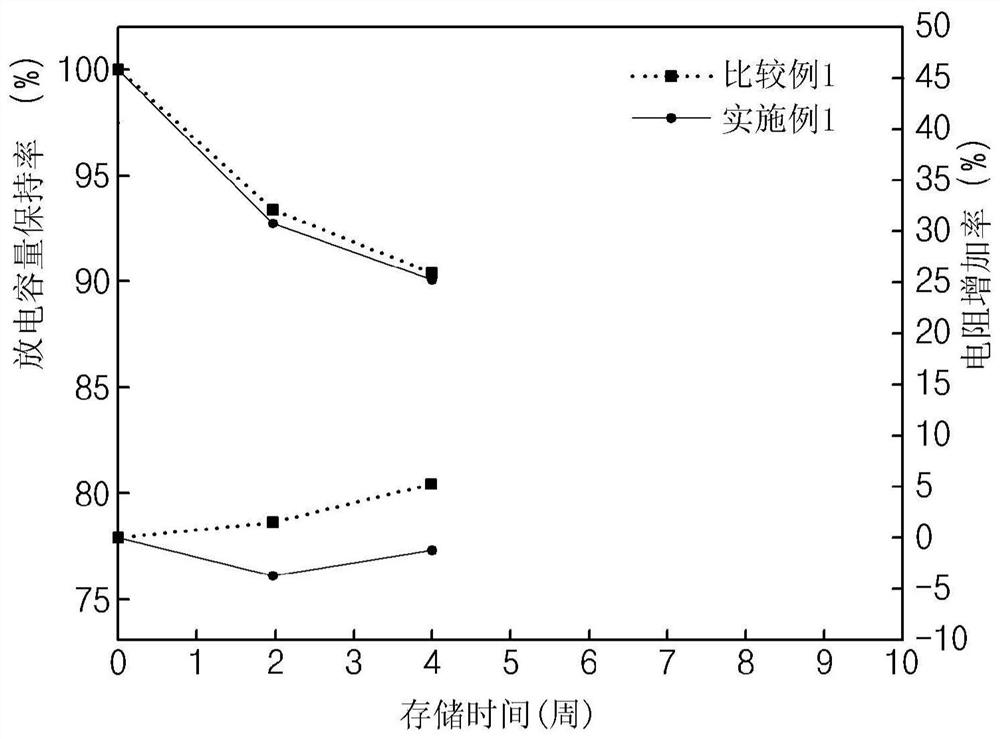

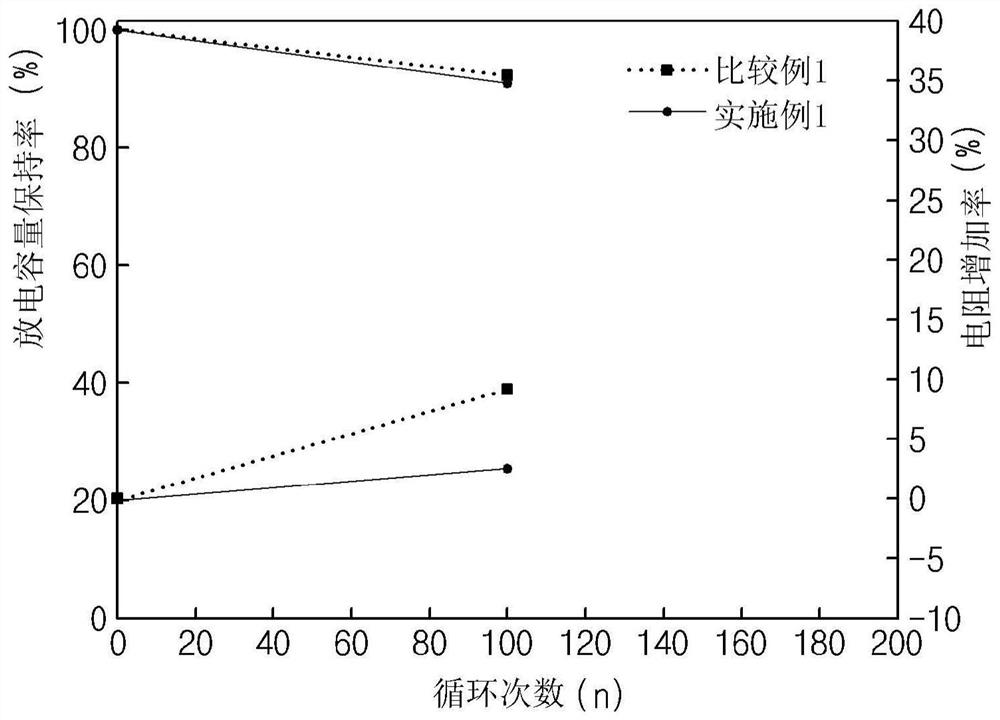

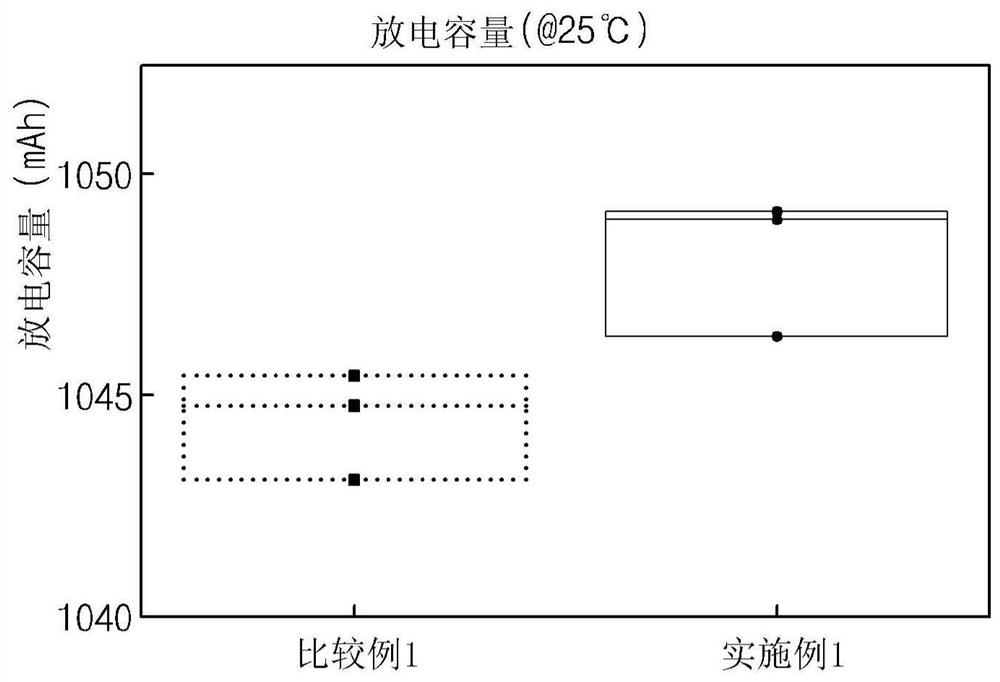

[0162] Experimental example 1: Evaluation of storage characteristics at high temperature (60°C) (1)

[0163] After each lithium secondary battery prepared in Example 1 and Comparative Example 1 was activated at a CC of 0.1C, degassing was performed.

[0164] Subsequently, each lithium secondary battery was charged to 4.20V at a CC of 0.33C under constant current-constant voltage (CC-CV) conditions at 25°C, then cut off at a current of 0.05C, and charged at a CC of 0.33C. Discharge to 2.5V. The above charging and discharging was defined as one cycle, and after one cycle was completed, the remaining capacity (initial remaining capacity) was measured using a PNE-0506 charging / discharging device (manufacturer: PNE SOLUTION Co., Ltd., 5V, 6A).

[0165]Then, each lithium secondary battery was recharged to 100% state of charge (SOC) at a CC of 0.33C, and then CC-CV charged at a CC of 0.33C after further storage at high temperature (60°C) for 2 weeks. After discharging, the remainin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com