Chitin-reinforced PGA-PLA composite material with controllable degradation period as well as preparation method and application thereof

A degradation cycle and composite material technology, applied in the field of polymer materials, can solve the problems of difficult control of the degradation cycle of composite materials and inability to apply, and achieve the effects of controllable degradation cycle, material cost reduction, and performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

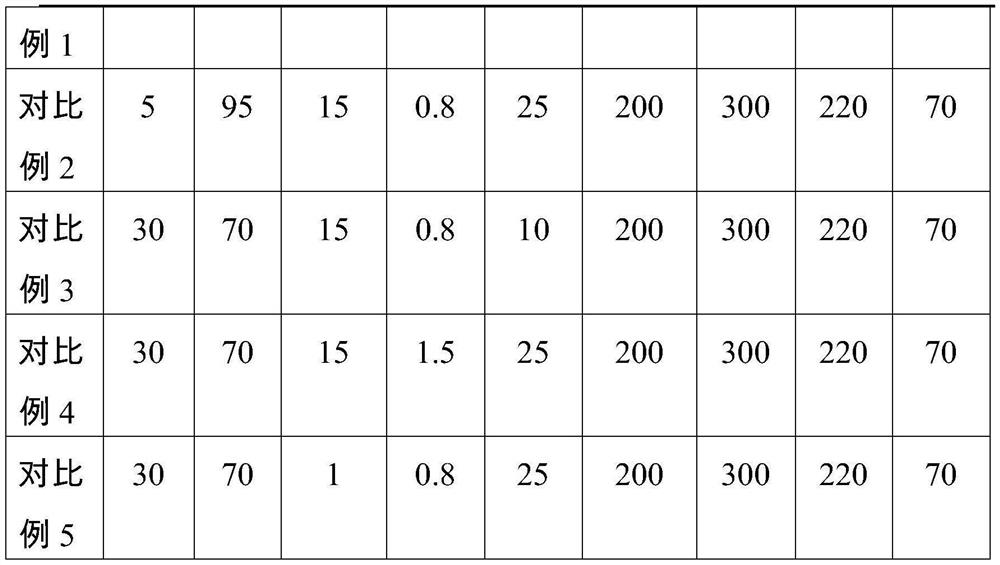

Examples

Embodiment Construction

[0026] In order to make the technical problems to be solved by the present invention, technical solutions and beneficial effects more clear, the present invention will be further described in detail below in conjunction with the embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0027] main ingreadient:

[0028] PGA, Inner Mongolia Pujing Polymer Materials Co., Ltd.;

[0029] PLA, 210, Zhejiang Hisun Biomaterials Co., Ltd.;

[0030] Shell powder, Suzhou Jiurui Biotechnology Co., Ltd.;

[0031] Hydrolysis-resistant agent, Kunshan Dingfa Chemical Co., Ltd.;

[0032] Lubricants, EBS, Kao;

[0033] Toughener PBAT, T801HT, Tunhe, Lanshan, Xinjiang.

[0034] Instruments and equipment:

[0035] Twin-screw extruder, CTE-35, Coperion Machinery;

[0036] High-speed mixer, HB-50A, Hongbao Machinery Co., Ltd.;

[0037] Injection machine, CJ120M, Chen Hsong Plastic M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com