Methanol modifier as well as preparation method and application thereof

A modifier, methanol technology, applied in the field of methanol modifier and its preparation, can solve the problems of low lubricating coefficient, swelling, fluff, etc., and achieve the effects of reducing wear of parts, improving lubricity, and increasing lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

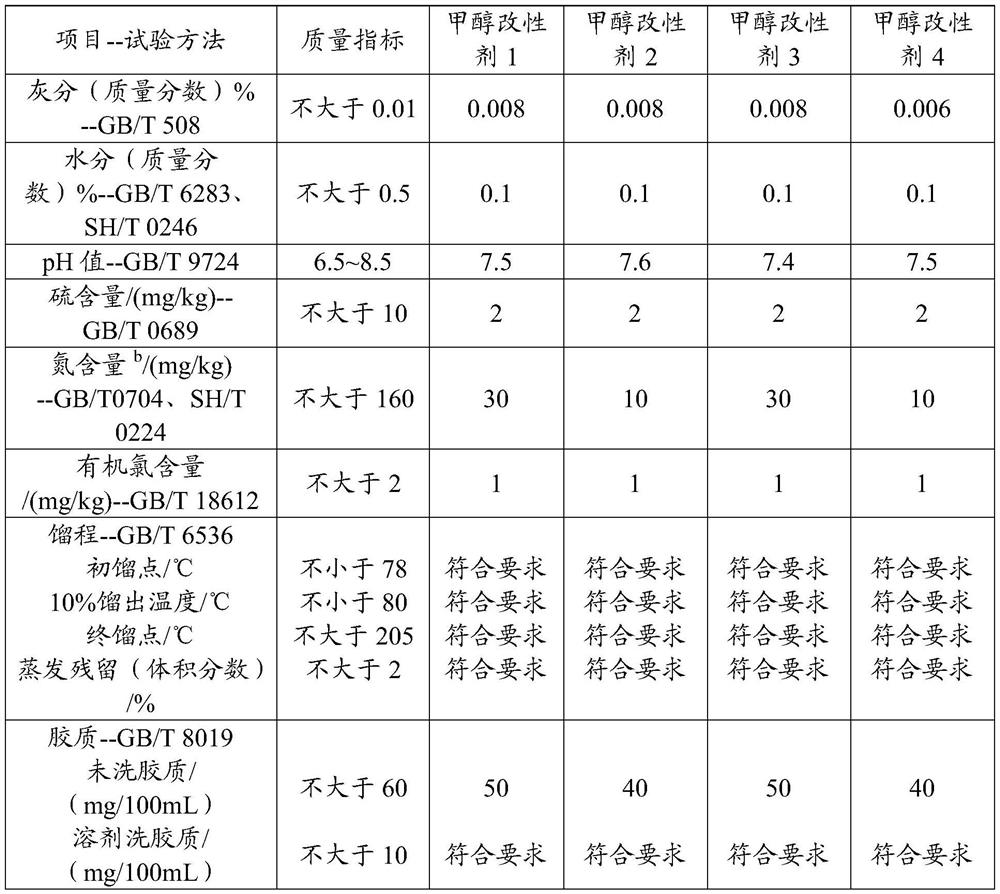

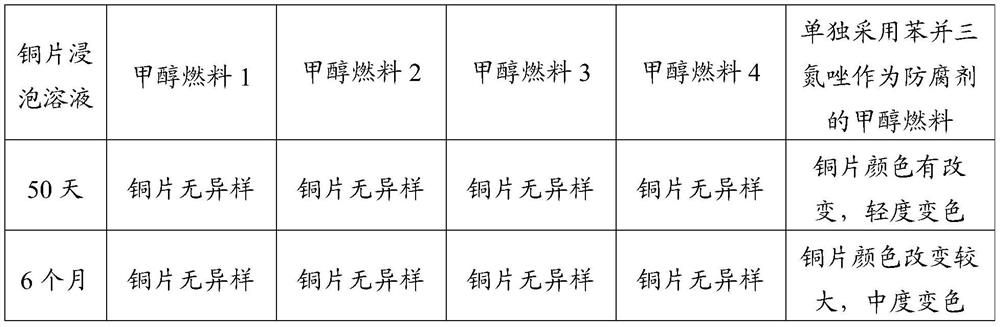

Embodiment 1

[0023] The methanol modifying agent in this embodiment includes benzotriazole, mercaptobenzothiazole, tolyltriazole, organic silicon and N,N-disalicylidene-1,2 propylenediamine, The corrosion inhibitor blended according to the weight ratio of 2:1:1:1:1 is composed of polyisobutylamine and polyetheramine, and the detergent is blended according to the weight ratio of 1:2. It is composed of propanol and isobutanol, and a low-carbon alcohol blended in a 2:1 weight ratio, as well as vegetable oil. Wherein, the weight proportion of corrosion inhibitor, detergent, low-carbon alcohol and vegetable oil is: 30:10:30:10.

[0024] The methanol modifier of the above-mentioned weight ratio is prepared by the following preparation method, and the specific steps are:

[0025] (1) Weigh the following raw materials in parts by weight respectively: 30 parts of corrosion inhibitors, 10 parts of detergents, 30 parts of low-carbon alcohols, and 10 parts of vegetable oils;

[0026] (2) Slowly pour...

Embodiment 2

[0031] The methanol modifying agent in this embodiment includes benzotriazole, mercaptobenzothiazole, tolyltriazole, organic silicon and N,N-disalicylidene-1,2 propylenediamine, The corrosion inhibitor blended according to the weight ratio of 3:1:1:1:1 is composed of polyisobutylamine and polyetheramine, and the detergent is blended according to the weight ratio of 1.5:2. It is composed of propanol and isobutanol, and a low-carbon alcohol blended in a 3:1 weight ratio, as well as vegetable oil. Wherein, the weight ratio of corrosion inhibitor, detergent, low-carbon alcohol and vegetable oil is: 40:20:40:20.

[0032] The methanol modifier of the above-mentioned weight ratio is prepared by the following preparation method, and the specific steps are:

[0033] (1) Take the following raw materials in parts by weight respectively: 40 parts of corrosion inhibitors, 20 parts of detergents, 40 parts of low-carbon alcohols, and 20 parts of vegetable oils;

[0034] (2) Slowly pour the...

Embodiment 3

[0039] The methanol modifying agent in this embodiment includes benzotriazole, mercaptobenzothiazole, tolyltriazole, organic silicon and N,N-disalicylidene-1,2 propylenediamine, The corrosion inhibitor blended according to the weight ratio of 4:1:1:1:1 is composed of polyisobutylamine and polyetheramine, and the detergent is blended according to the weight ratio of 1:2. It is composed of propanol and isobutanol, and a low-carbon alcohol blended in a 4:1 weight ratio, as well as vegetable oil. Wherein, the weight ratio of corrosion inhibitor, detergent, low-carbon alcohol and vegetable oil is: 30:10:40:20.

[0040] The methanol modifier of the above-mentioned weight ratio is prepared by the following preparation method, and the specific steps are:

[0041] (1) Weigh the following raw materials in parts by weight respectively: 30 parts of corrosion inhibitors, 10 parts of detergents, 40 parts of low-carbon alcohols, and 20 parts of vegetable oils;

[0042](2) Slowly pour the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com