Toner and preparation method thereof

A toner and colorant technology, applied in the field of toner, can solve the problems of printing quality and environmental adverse effects, unreasonable printing effect, easy caking in storage, etc., achieve good image quality, reduce burial, and improve storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

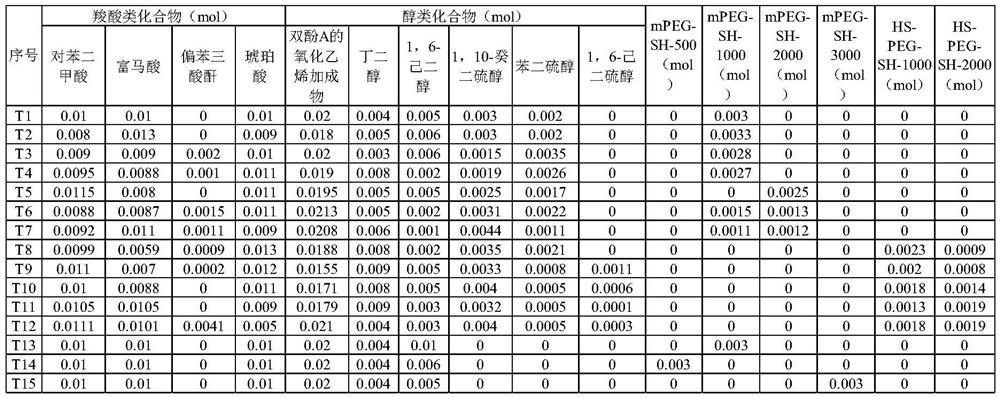

preparation example Construction

[0029] Preparation method of toner

[0030] Use emulsification method among the present invention, comprise the following steps:

[0031]

[0032] Add carboxylic acid compounds, alcohol compounds and catalysts into the reaction vessel, under the condition of nitrogen protection, stir and react at 70-150°C for 5-8 hours to obtain polyester resin

[0033] In the present invention, the polycondensation reaction of the polyester resin is performed at a temperature lower than or equal to 150°C.

[0034] The reaction temperature is preferably higher than or equal to 70°C but not higher than 150°C; more preferably higher than or equal to 110°C but not higher than 140°C.

[0035] It is preferable to set the reaction temperature to be higher than or equal to 70° C., since there will be no decrease in reactivity due to deterioration of monomer solubility or catalyst activity, and no inhibition of increase in molecular weight. It is also preferable to set the reaction temperature no...

Embodiment 1

[0109] Preparation of Toner-T1

[0110] 0.01mol (1.66g) terephthalic acid, 0.01mol (1.16g) fumaric acid, 0.01mol (1.18g) succinic acid, 0.02mol (6.32g) bisphenol A ethylene oxide adduct, 0.004mol (0.472 g) Butanediol, 0.005mol (0.590g) 1,6-hexanediol, 0.0979g (0.00032mol) dibutyltin oxide were added to the reaction vessel, stirred under nitrogen protection, and polycondensed at 130°C for 7 hours, Then add 0.003mol (0.618g) of 1,10-decanedithiol and 0.002mol (0.284g) of benzenedithiol, and continue to react at 150°C for 7h to obtain a polyester resin.

[0111] Disperse the prepared polyester resin in a homogenizer at 3000rpm for 3 minutes, add water to adjust the solid content to 10%, and then add 0.003mol mPEG-SH-1000 (mPEG-SH-1000 means that the molecular weight of mPEG-SH is 1000) , after air oxidation, high-speed stirring and dispersion to obtain polyester resin emulsion.

[0112] Add 0.8g of carbon black dispersion and 0.8g of carnauba wax dispersion, adjust the pH val...

Embodiment 2

[0114] Preparation of Toner-T2

[0115] 0.008mol (1.328g) terephthalic acid, 0.013mol (1.508g) fumaric acid, 0.009mol (1.062g) succinic acid, 0.018mol (5.688g) bisphenol A ethylene oxide adduct, 0.005mol (0.59 g) Butanediol, 0.006mol (0.709g) 1,6-hexanediol, 0.0979g (0.00032mol) dibutyltin oxide were added to the reaction vessel, stirred under the protection of nitrogen, and polycondensed at 70°C for 8 hours, Then add 0.003mol (0.618g) of 1,10-decanedithiol and 0.002mol (0.284g) of benzenedithiol, and continue to react at 150°C for 7h to obtain a polyester resin.

[0116] Disperse the prepared polyester resin in a homogenizer at 5000rpm for 5 minutes, add water to adjust the solid content to 18%, and then add 0.0033mol mPEG-SH-1000 (mPEG-SH-1000 means that the molecular weight of mPEG-SH is 1000) , after air oxidation, high-speed stirring and dispersion to obtain polyester resin emulsion.

[0117] Add 0.8g of carbon black dispersion and 0.8g of carnauba wax dispersion, adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com