Preparation method of rose geranium essential oil microcapsules with good oxidation resistance and antibacterial properties

An antioxidant, geranium technology, applied in microcapsule preparations, microsphere preparation, food ingredients as antioxidants, etc., can solve the problems of functional properties to be improved, poor thermal stability of core materials, etc., to improve application value, good antibacterial performance, the effect of broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

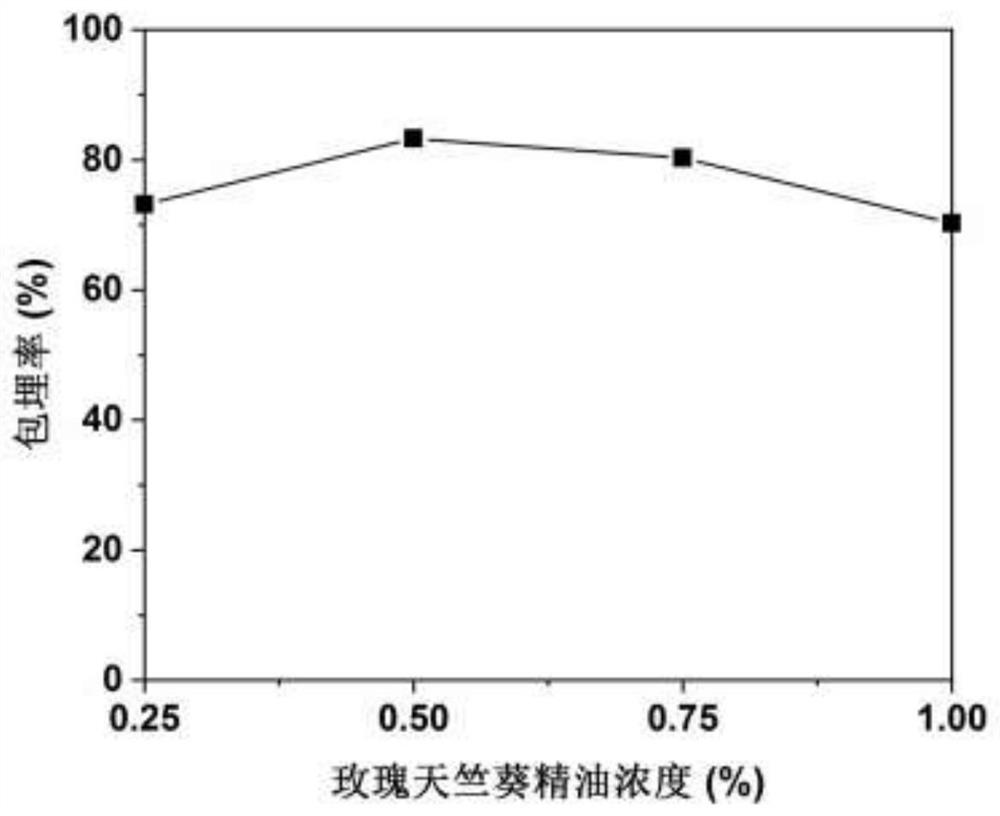

[0047] According to the following method, using whey protein isolate (abbreviated as WPI) and chitosan hydrochloride (abbreviated as CH) as wall materials, rose geranium essential oils of different concentrations as core materials, and using complex coacervation method to prepare rose geranium essential oil microcapsules :

[0048] (1) Dissolve whey protein isolate and chitosan hydrochloride in deionized water respectively, stir at 600rpm at room temperature for 6h, make it fully hydrated, and obtain whey protein isolate dispersion and shell protein with a mass fraction of 1% respectively. Polysaccharide hydrochloride dispersion.

[0049] (2) Add an appropriate amount of rose geranium essential oil to the whey protein isolate dispersion obtained in step (1), to obtain a whey protein isolate mass fraction of 1%, and rose geranium essential oil mass fractions to be 0.25%, 0.5%, 0.75%, and 1.0% respectively % of several groups of mixtures.

[0050] (3) Shear and homogenize seve...

Embodiment 2

[0063] According to the following method, whey protein isolate (abbreviated as WPI) and chitosan hydrochloride (abbreviated as CH) are used as the wall material, and the rose geranium essential oil is the core material, and the rose geranium essential oil microcapsules are prepared by the complex coacervation method:

[0064] (1) Dissolve whey protein isolate and chitosan hydrochloride in deionized water respectively, stir at 600rpm at room temperature for 6h, make it fully hydrated, and obtain whey protein isolate dispersion and shell protein with a mass fraction of 1% respectively. Polysaccharide hydrochloride dispersion.

[0065] (2) Add rose geranium essential oil with a mass fraction of 0.5% to the whey protein isolate dispersion liquid obtained in step (1) to obtain a mixed liquid.

[0066] (3) Shear and homogenize the mixed solution obtained in step (2): shear speed 12000rpm, shear time 3min; homogeneous pressure 55MPa, cycle times 3 times; then add the shell obtained i...

Embodiment 3

[0088] According to the following method, whey protein isolate (abbreviated as WPI) and carboxymethyl chitosan (abbreviated as CMCS) are used as wall materials, and rose geranium essential oils of different concentrations are used as core materials, and rose geranium essential oil microcapsules are prepared by complex coacervation method :

[0089] (1) Dissolve whey protein isolate and carboxymethyl chitosan in deionized water respectively, stir at 600rpm at room temperature for 6h, make it fully hydrated, and obtain whey protein isolate dispersion and carboxymethyl chitosan with a mass fraction of 1% respectively. Methyl Chitosan Dispersion.

[0090] (2) Add an appropriate amount of rose geranium essential oil to the whey protein isolate dispersion obtained in step (1), to obtain a whey protein isolate mass fraction of 1%, and rose geranium essential oil mass fractions to be 0.25%, 0.5%, 0.75%, and 1.0% respectively % of several groups of mixtures.

[0091] (3) Shear and ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com