Novel ultrafiltration water treatment system

A treatment system and ultrafiltration water technology, applied in filtration treatment, water/sewage treatment, food industry wastewater treatment, etc., can solve the problems of reduced safety and hygiene level, limited filtration effect of filtration system, insufficient filtration of concentrated water, etc. To achieve the effect of improving the level of safety and hygiene, improving the level of safety and hygiene, and reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

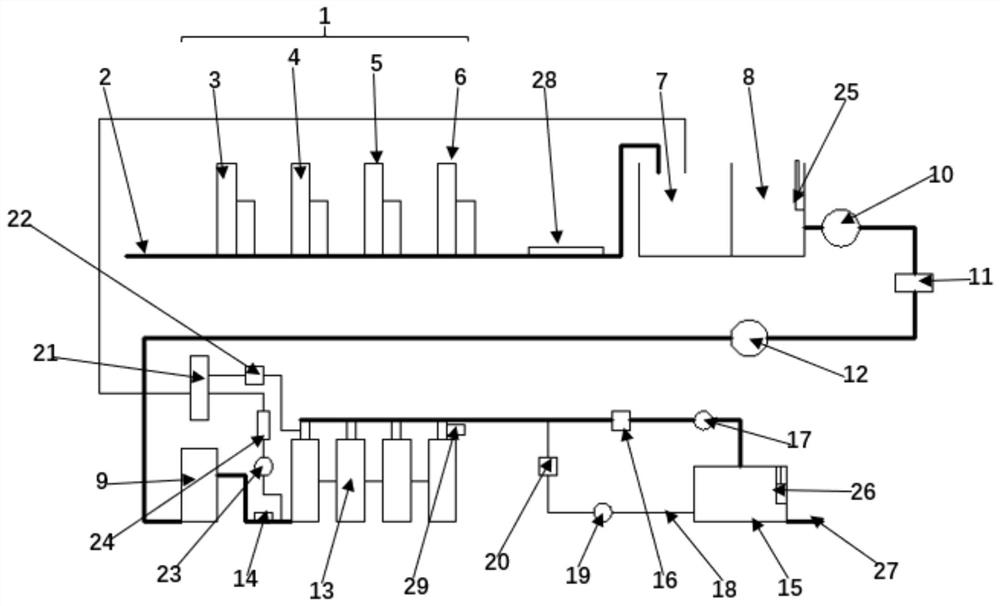

[0018] Such as figure 1 Shown, a kind of novel ultrafiltration water treatment system, it comprises dosing system 1 and water pipeline 2, and described dosing system 1 is installed on the water pipeline 2, and described dosing system 1 is added by polyacrylamide Medicine box 3, polyaluminum chloride medicine box 4, sodium hydroxide medicine box 5 and sodium hypochlorite medicine box 6 are composed, the right end of the water pipeline 2 is connected with a sedimentation tank 7, and the right side of the sedimentation tank 7 is An intermediate pool 8 is installed, and the intermediate pool 8 is connected with a self-cleaning water filter box 9 through a water delivery pipeline 2, and the water delivery pipeline 2 of the section between the intermediate pool 8 and the self-cleaning water filter box 9 is respectively equipped with a raw water booster ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com