Modified aeolian sand reinforced and toughened thermoplastic resin building template composition and preparation method thereof

A thermoplastic resin and building formwork technology, applied in the field of polymer matrix building materials, can solve the difficult problems of improving the comprehensive performance of thermoplastic resin building formwork, endangering the ecological environment of mines and human survival, and being unable to realize large-scale industrial production. To achieve the effect of simplifying the management of production materials and processing operations, improving mechanical properties and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

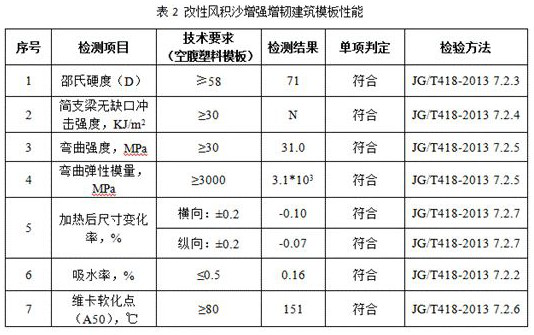

Examples

Embodiment 1

[0037] Components of aeolian sand-reinforced and toughened thermoplastic resin building formwork: 61 parts of a mixture of homopolymerized PP resin and copolymerized PP resin with a mass ratio of 4.5:1, 35 parts of modified aeolian sand, 1.5 parts of LLDPE, boric acid ester 1.0 parts of P7S, 0.15 parts of anti-aging agent 1010, 0.15 parts of anti-aging agent 168, 1.2 parts of titanium dioxide. The modified aeolian sand is modified by grinding and refining with 3% polyfunctional borate surfactant P20, with a particle size of 900 mesh. Put all the components into the mixer, mix for 15 minutes, add the mixture from the hopper of the extruder, melt and extrude through the twin-screw extruder, cool, dry, and pelletize to obtain aeolian sand-reinforced thermoplastic building formwork composition . The heating temperature range of the extruder is 172°C in the feeding section, 185°C in the melting section, 190°C in the homogenizing section, and 188°C in the extruding temperature of t...

Embodiment 2

[0039] Components of modified aeolian sand-reinforced and toughened thermoplastic resin building formwork: 55.5 parts of a mixture of homopolymerized PP resin and copolymerized PP resin at a mass ratio of 5.5:1, 40 parts of modified aeolian sand, 2 parts of LLDPE, poly 1.0 parts of vinyl wax, 0.25 parts of anti-aging agent 1010, 0.25 parts of anti-aging agent 168, 1.0 part of titanium dioxide. The modified aeolian sand is modified by grinding and refining with 3% polyfunctional borate surfactant P20, with a particle size of 900 mesh. Put all the components into the mixer, mix for 15 minutes, add the mixture from the hopper of the extruder, melt and extrude through the twin-screw extruder, cool, dry, and pelletize to obtain aeolian sand-reinforced thermoplastic building formwork composition . The heating temperature range of the extruder is 172°C in the feeding section, 185°C in the melting section, 190°C in the homogenizing section, and 188°C in the extruding temperature of t...

Embodiment 3

[0041]Components of modified aeolian sand reinforced and toughened thermoplastic resin building formwork: 55.5 parts of a mixture of homopolymerized PP resin and copolymerized PP resin with a mass ratio of 6.2:1, 40 parts of modified aeolian sand, 2 parts of LLDPE, boron 1.0 parts of acid ester P7S, 0.25 parts of anti-aging agent 1010, 0.25 parts of anti-aging agent 168, 1.0 parts of titanium dioxide. The modified aeolian sand is modified by grinding and refining with 3% polyfunctional borate surfactant P20, with a particle size of 900 mesh. Put all the components into the mixer, mix for 15 minutes, add the mixture from the hopper of the extruder, melt and extrude through the twin-screw extruder, cool, dry, and pelletize to obtain aeolian sand-reinforced thermoplastic building formwork composition . The heating temperature range of the extruder is 175°C in the feeding section, 183°C in the melting section, 192°C in the homogenizing section, and 190°C at the head extrusion tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com