Mxene-based flame-retardant unsaturated resin material and preparation method thereof

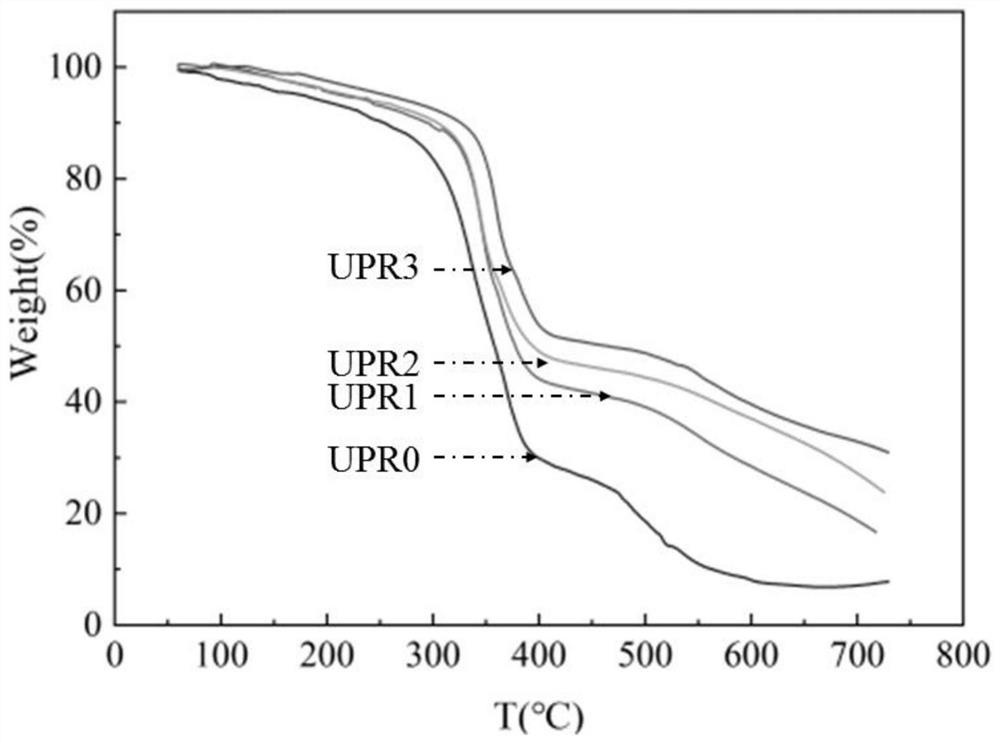

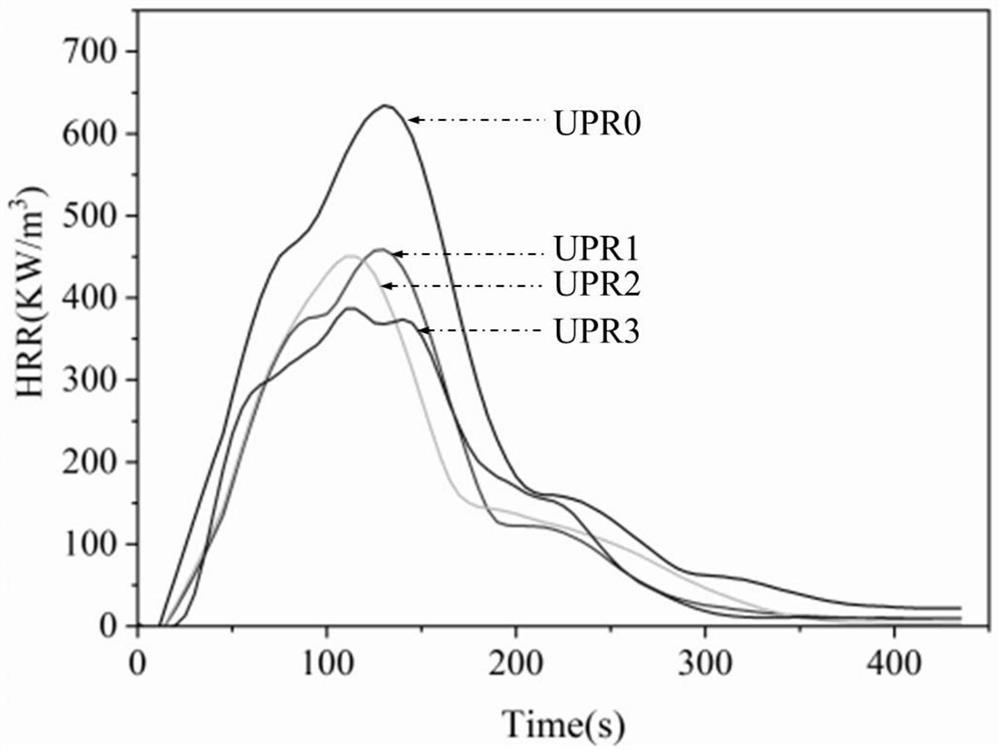

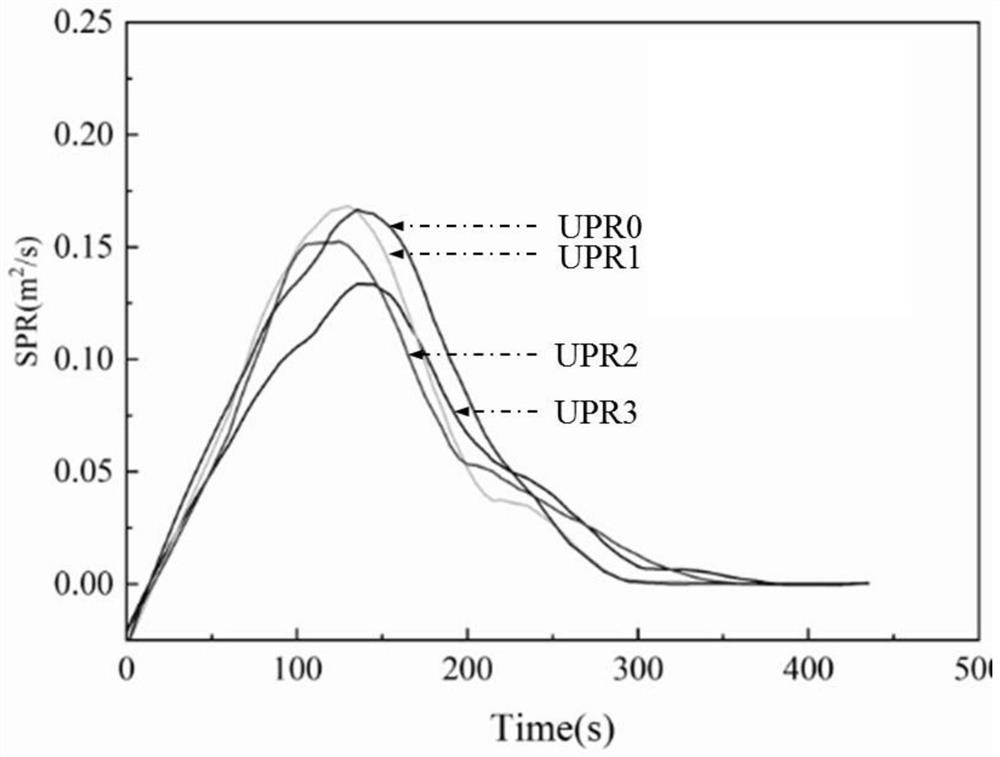

A resin material and unsaturated technology, which is applied in the field of Mxene-based flame-retardant unsaturated resin materials and its preparation, can solve the problems of producing toxic smoke, a large amount of smoke, and affecting the mechanical properties of polymers, so as to improve the flame-retardant performance , toughness and continuity improvement, and the effect of reducing the total amount of heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. MXene (Ti 3 C 2 x n ) Preparation of materials

[0030] Dissolve 1g LiF in 30mL 6M HCl solution to prepare etching solution, and then 1gTi 3 A1C 2 Slowly add the above etching solution to react for 7h. After the reaction is completed, wash with deionized water and centrifuge, and repeat the washing several times until a dark green supernatant with pH>6 is obtained. Then, the obtained precipitate was sonicated in an ice bath in absolute ethanol for 1 h, centrifuged, and then 40 mL of deionized water was added to the precipitate, sonicated for 20 min, and after centrifugation, the supernatant was freeze-dried for 24 hours to obtain the MXene material.

[0031] 2. Preparation of MXene-based flame-retardant unsaturated resin materials and MXene-based flame-retardant unsaturated resin molding materials

[0032] (1) Selection of the amount of ammonium polyphosphate (APP)

[0033]The total mass of the MXene-based flame-retardant unsaturated resin material is set to 9...

Embodiment 2

[0047] 1. MXene (Ti 3 C 2 x n ) modification

[0048] (1) Weigh 0.2g of the MXene material prepared in Example 1 and disperse it in 50mL of absolute ethanol, seal it with a plastic wrap and ultrasonically disperse it for 30min to obtain a uniform dispersion of the MXene material;

[0049] (2) After adding 1mL 1-butyl-3-methylimidazolium hexafluorophosphate (IL) and 20mL deionized water, magnetically stir, and add 0.1mL (2 drops) of silane coupling agent KH550 (3 -aminopropyltriethylsilane), stirred and reacted for 1 hour;

[0050] (3) Suction filtration and washing with absolute ethanol for 3 times, drying and grinding to obtain the modified MXene material.

[0051] 2. Preparation of MXene-based flame-retardant unsaturated resin materials and MXene-based flame-retardant unsaturated resin molding materials

[0052] The total mass of the MXene-based flame-retardant unsaturated resin material is set to 94 parts, the content of APP is set to 17 parts, and the content of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com