A kind of preparation method of completely degradable solid corrosion inhibitor

A completely degradable corrosion inhibitor technology, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of excessive corrosion inhibitor waste, oil well blockage, and large anti-corrosion blocks, etc., to achieve Anti-corrosion and dissolution, long service life, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

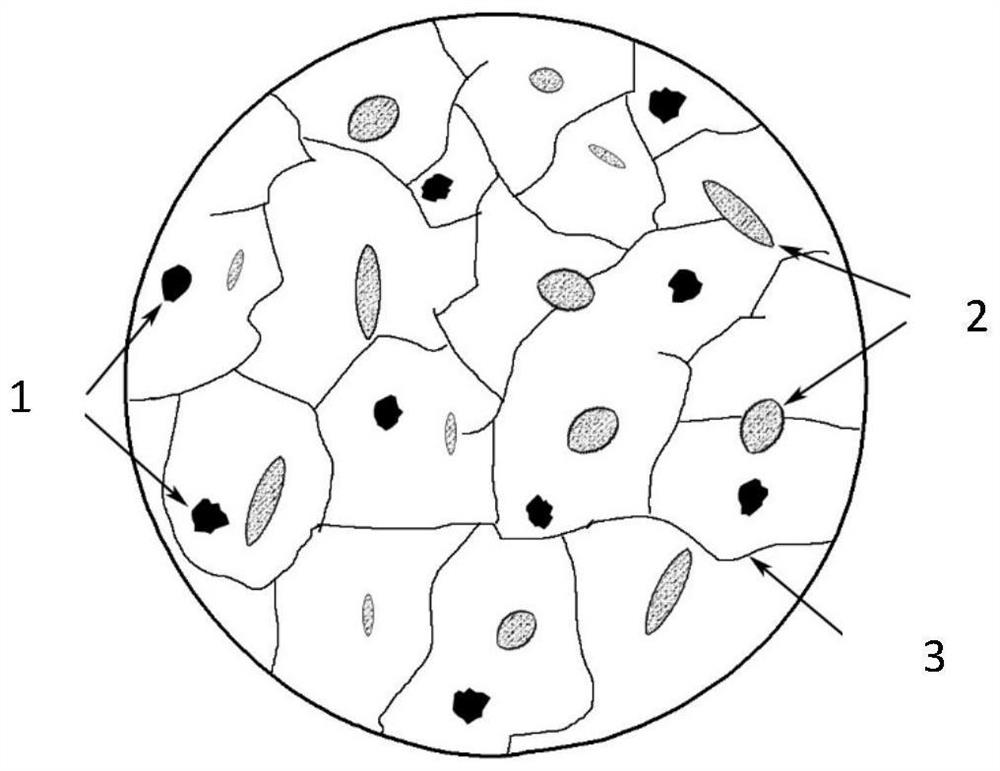

[0031] The preparation method of the corrosion inhibitor of the present invention is as follows: firstly, polylactic acid and other components (toughening, increasing oil absorption) are copolymerized in a reaction kettle to obtain a lactic acid copolymer with good toughness, oil absorption and stability, which is used as a retarder. Slow-release matrix material for etchant;

[0032] Slowly add the corrosion inhibitor and auxiliary agent to the lactic acid copolymer and stir evenly;

[0033] Then add a certain amount of zinc powder or aluminum powder, stir evenly, to improve the slow release performance of the corrosion inhibitor and adjust the density of the corrosion inhibitor;

[0034] Further adding an appropriate amount of peroxide, stirring quickly and evenly, slightly cross-linking the lactic acid copolymer, so that the corrosion inhibitor phase encapsulated in the polymer is more stable, and the corrosion inhibitor has a longer service life.

[0035] Finally, it is gr...

Embodiment 1

[0051] 1) The lactic acid and the catalyst stannous chloride were mixed uniformly in a mass ratio of 100:0.3 and then put into a kettle type reactor, decompressed at 60°C (90Pa) for 2h, then heated to 80°C at 90Pa for 2h reaction, and then heated up The reaction was carried out at 100 °C for 2 h, and then heated to 120 °C for 2 h to obtain a lactic acid oligomer.

[0052] 2) under 90Pa, be warming up to 140 ℃, continue to add ethylenedicaprolactone in the lactic acid oligomer in the polylactic acid reactor, the mass ratio of the quality of the feed and the lactic acid oligomer is 3:100, then heat up The reaction was carried out at 160 °C for 2 hours, and then heated to 180 °C for 2 hours to obtain a lactic acid copolymer.

[0053] 3) Keep the pressure of the reaction kettle at 90Pa, reduce the temperature of the reaction kettle to 140°C, slowly add the corrosion inhibitor imidazoline to the polymer of lactic acid, the mass of the corrosion inhibitor added is 40% of the mass of...

Embodiment 2

[0062] 1) The lactic acid and the catalyst stannous chloride were mixed uniformly in a mass ratio of 100:0.4 and then put into a kettle type reactor, decompressed at 65°C (85Pa) for 1 hour, then heated to 80°C at 85Pa for 3 hours, and then heated again. The reaction was carried out at 100 °C for 3 hours, and finally heated to 120 °C for 3 hours to obtain lactic acid oligomers.

[0063] 2) Under 85Pa, heat up to 140°C, continue to add caprolactone to the lactic acid oligomer in the polylactic acid reactor, and the mass ratio of the mass of the feed to the lactic acid is 7:100, then heat up to 160°C and react for 3h , and then the temperature was raised to 180 °C for 3 h to obtain a lactic acid copolymer.

[0064] 3) keep reactor pressure 85Pa, the temperature of reactor is reduced to 140 ℃, in the polymer of lactic acid, slowly add ethylenediaminetetramethylenephosphonic acid, and the quality that diaminetetramethylenephosphonic acid adds is lactic acid quality 70%, and stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com