Preparation method of bean dreg extruded puffed food

A technology of puffed food and bean dregs, which is applied in the forming of food, the function of food ingredients, food ingredients, etc., to achieve the effects of reducing environmental pollution, high dietary fiber, water absorption and water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

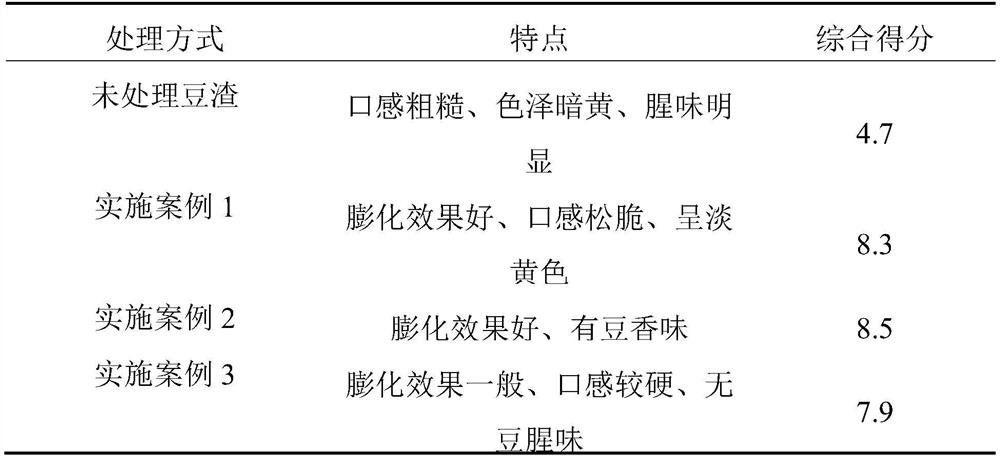

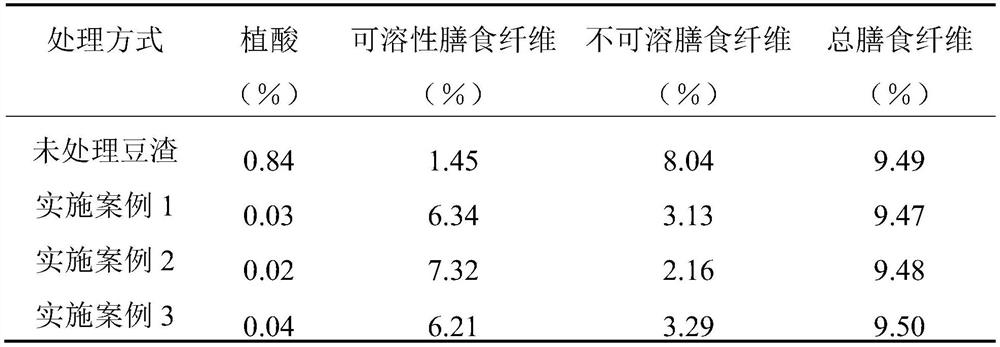

Embodiment 1

[0031] (1) Enzyme treatment of wet bean dregs

[0032] Add 3‰ (3g) of phytase to 1000g of fresh bean dregs, and perform dephytic acid treatment at 45°C for 2h;

[0033] (2) Maillard reaction for flavoring

[0034] Take the pretreated bean dregs obtained in step (1), add 5% (50 g) of glucose and 5% (50 g) of arginine by the mass of the bean dregs, and react in a sterilizing pot at 190° C. for 0.5 h;

[0035] (3) Material compatibility

[0036] The bean dregs in step (2) are taken, dried at 75° C. until the water content is 20%, and the dried bean dregs are ground and sieved with a high-speed universal grinder. Okara powder is mixed with cornstarch and wheat germ in a mass ratio of 8:2:1;

[0037] (4) Moisture adjustment

[0038] The moisture content of the extruded raw material of step (3) is adjusted to 35%;

[0039] (5) Preparation of extrusion puffed products

[0040] Put the raw materials of step (4) into the extrusion extruder, the rotating speed is 110r / min, the tem...

Embodiment 2

[0042] (1) Enzyme treatment of wet bean dregs

[0043] Add 5‰ (5g) of phytase to 1000g of fresh bean dregs, and perform dephytic acid treatment at 65°C for 2h;

[0044] (2) Maillard reaction for flavoring

[0045] Take the pretreated bean dregs obtained in step (1), add 5% (50 g) of glucose and 5% (50 g) of arginine by the quality of the bean dregs, and react in a sterilizing pot at 100° C. for 1.0 h;

[0046] (3) Material compatibility

[0047] Take the bean dregs in step (2), dry them at 85° C. until the water content is 15%, and use a high-speed universal grinder to grind the dried bean dregs into powder and sieve. Okara powder is mixed with cornstarch and wheat germ in a mass ratio of 10:3:1;

[0048] (4) Moisture adjustment

[0049] The moisture content of the extruded raw material of step (3) is adjusted to 30%;

[0050] (5) Preparation of extrusion puffed products

[0051] Put the raw materials of step (4) into the extrusion extruder, the rotating speed is 110r / mi...

Embodiment 3

[0053] (1) Enzyme treatment of wet bean dregs

[0054] To 1000g of fresh bean dregs, add phytase with a quality of 4‰ (4g) of bean dregs, and perform dephytic acid treatment at 55°C for 2 hours;

[0055] (2) Maillard reaction for flavoring

[0056] Take the pretreated bean dregs obtained in step (1), add 5% (50 g) of glucose and 5% (50 g) of arginine in the bean dregs mass, and react in a sterilizing pot at 90° C. for 2.0 h;

[0057] (3) Material compatibility

[0058] The bean dregs in step (2) are taken, dried at 65° C. until the water content is 30%, and the dried bean dregs are ground and sieved with a high-speed universal grinder. Okara powder is mixed with cornstarch and wheat germ in a mass ratio of 8:4:1;

[0059] (4) Moisture adjustment

[0060] The moisture content of the extruded raw material of step (3) is adjusted to 25%;

[0061] (5) Preparation of extrusion puffed products

[0062] Put the raw materials of step (4) into the extrusion extruder, the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com