MDF tail gas up-to-standard emission process

The technology of tail gas and process is applied in the field of tail gas treatment of wood-based panel manufacturing, which can solve the problems of uncontrolled tail gas components, high formaldehyde content and high dust content, and achieves harmless emission, simple process method, and reduced processing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

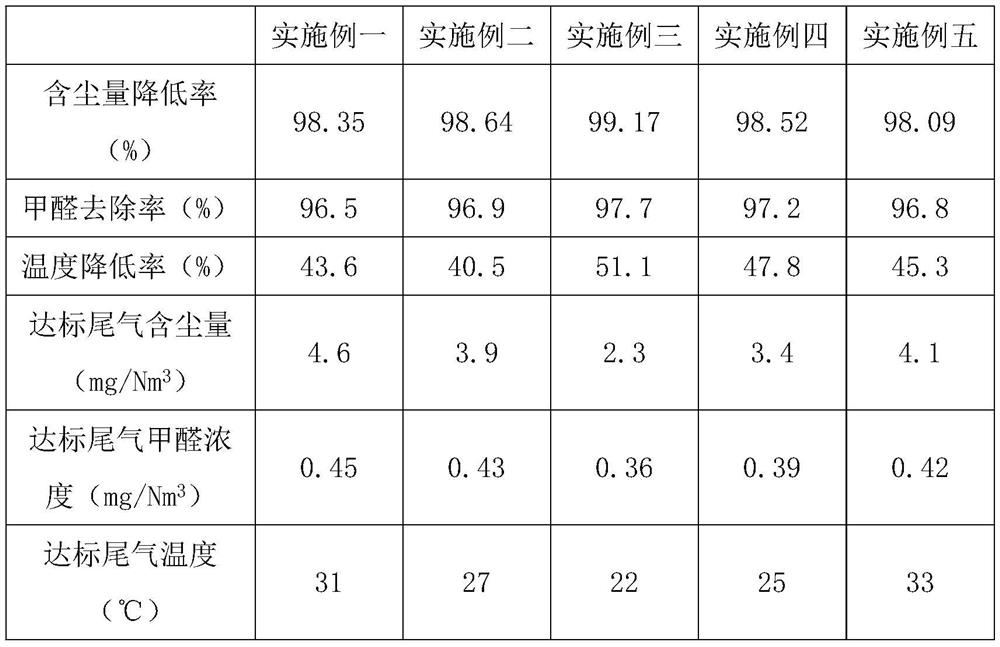

Examples

Embodiment 1

[0021] A kind of MDF tail gas up-to-standard discharge process that the present invention proposes comprises the following steps:

[0022] S1. Control the air intake speed to 1.8L / s, pass the MDF tail gas discharged from the production into the spray tower, and control the amount of spray water to 0.5m 3 / h, the temperature of the spray water is 2°C, and the spray water is used for spray treatment to obtain the spray liquid, which is passed into the condensation pipe and cooled to normal temperature;

[0023] S2. Add the cooled spray liquid in step S1 to the reactor, adjust the pH value to neutral, control the mass ratio of the spray liquid to the activated carbon-supported catalyst to be 1:0.02, add the activated carbon-supported catalyst, and heat up to 50°C , after stirring and reacting for 3h, leave it to stand and centrifuge to obtain the treatment solution and sediment, and the treatment solution is reused in step S1 to replace the spray water. The activated carbon-loade...

Embodiment 2

[0026] A kind of MDF tail gas up-to-standard discharge process that the present invention proposes comprises the following steps:

[0027] S1. Control the air intake speed to 2L / s, pass the MDF tail gas discharged from the production into the spray tower, and control the amount of spray water to 0.8m 3 / h, the temperature of the spray water is 5°C, and the spray water is used for spray treatment to obtain the spray liquid, which is passed into the condensation pipe and cooled to normal temperature;

[0028] S2. Add the cooled spray liquid in step S1 to the reactor, adjust the pH value to neutral, control the mass ratio of the spray liquid to the activated carbon-supported catalyst to be 1:0.03, add the activated carbon-supported catalyst, and raise the temperature to 55°C , after stirring and reacting for 3.5h, leave it to stand and centrifuge to obtain the treatment solution and sediment, and the treatment solution is reused in step S1 to replace the spray water. The activate...

Embodiment 3

[0031] A kind of MDF tail gas up-to-standard discharge process that the present invention proposes comprises the following steps:

[0032] S1. Control the air intake speed to 2.2L / s, pass the MDF tail gas discharged from the production into the spray tower, and control the amount of spray water to 1m 3 / h, the temperature of the spray water is 8°C, and the spray water is used for spray treatment to obtain the spray liquid, which is passed into the condensation pipe and cooled to normal temperature;

[0033] S2. Add the cooled spray liquid in step S1 to the reactor, adjust the pH value to neutral, control the mass ratio of the spray liquid to the activated carbon-supported catalyst to be 1:0.04, add the activated carbon-supported catalyst, and heat up to 60°C , after stirring and reacting for 4h, leave it to stand and centrifuge to obtain the treatment solution and sediment, and the treatment solution is reused in step S1 to replace the spray water. The activated carbon-loaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com