Metallurgical high-concentration nitrogen oxide flue gas rotary treatment device

A nitrogen oxide and treatment device technology, applied in gas treatment, combined device, inert gas generation and other directions, can solve the problems of affecting other structural stability, high pressure of absorption tower, large consumption of reducing agent, etc., to achieve the protection of structural integrity, The effect of high adsorption capacity and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

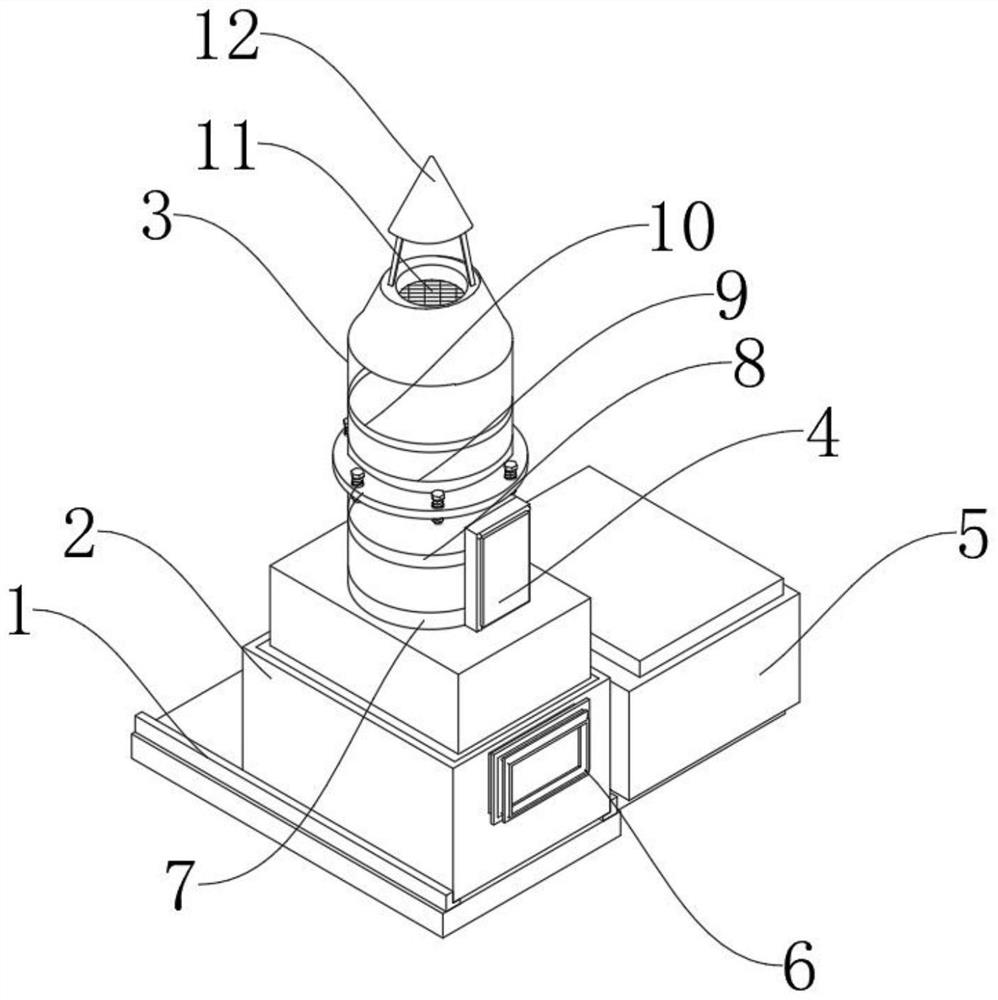

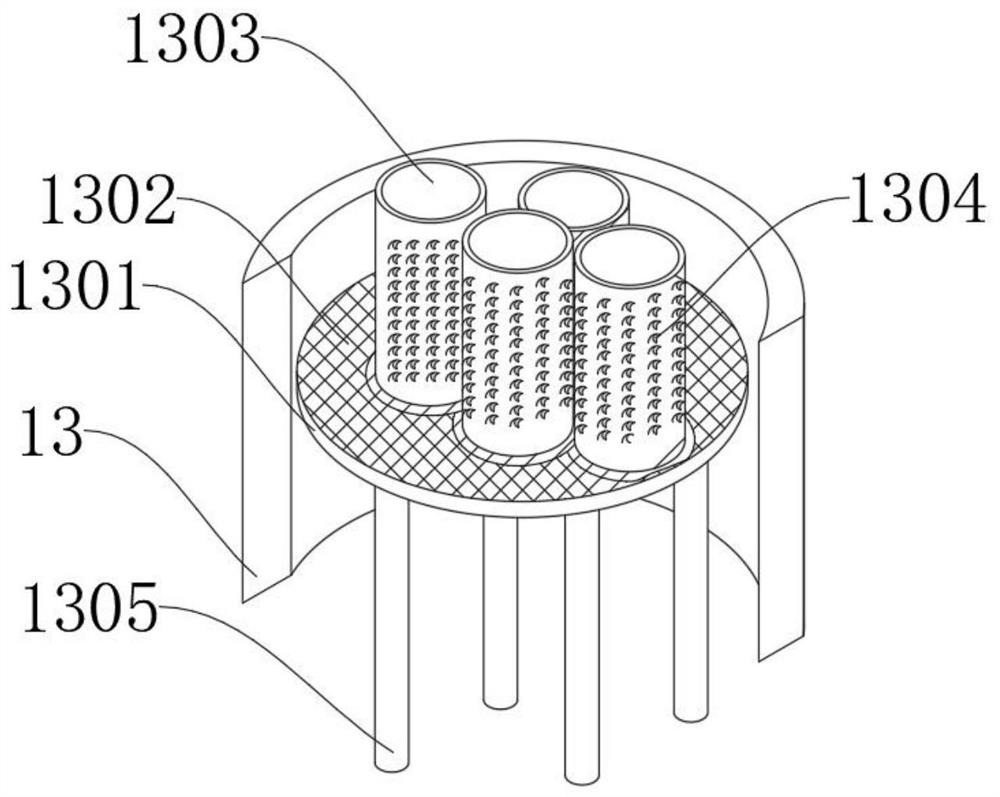

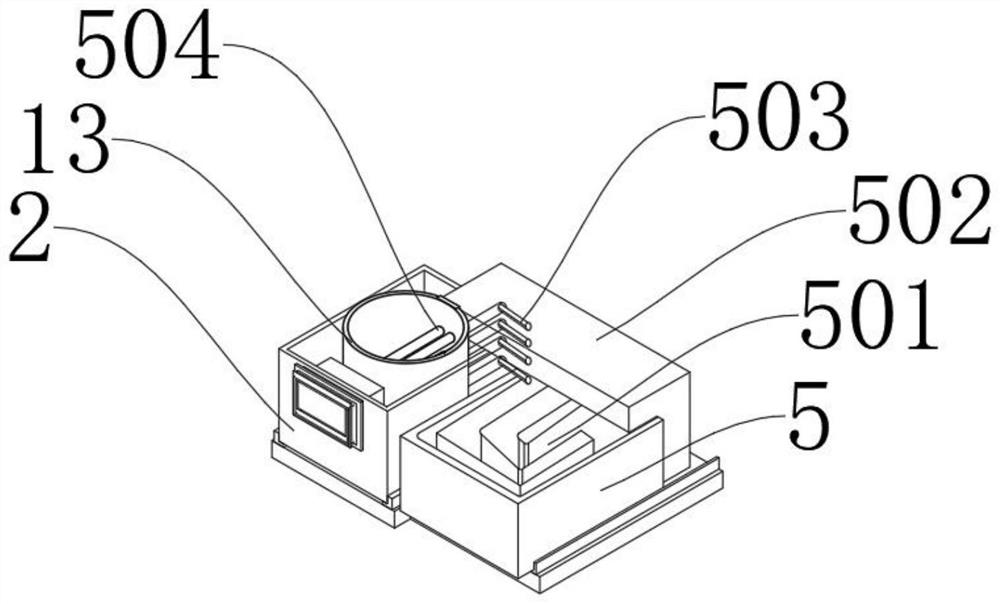

[0035] The present invention provides such Figure 1-9 A metallurgical high-concentration nitrogen oxide flue gas rotary treatment device is shown, including a steel frame base 1, a protective base 2 is fitted and fixed above the steel frame base 1, and the upper central axis of the protective base 2 is vertical An absorption tower 3 is installed, and the front side surface of the absorption tower 3 is integrally provided with a maintenance window 4, and a water tank 5 is arranged in parallel on the right side of the protective base 2, and a waste gas inlet 6 is opened in the middle of the front side of the protective base 2, and the absorption tower 3 A rotary mechanism 7 is installed at the inner bottom of the rotary mechanism 7, and a transitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com