Zinc stannate photocatalyst rich in oxygen vacancies, preparation method and application

A technology of photocatalyst and zinc stannate, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as air pollution and water pollution, and achieve equipment Low requirements, broadened response range, and good visible light response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) 0.18g of SnCl 2 2H 2 O, 0.109g of ZnCl 2 , 0.20 g of NaOH and 0.0032 g of sodium dodecylbenzenesulfonate (SDBS) were dissolved in 80 mL of 50% ethanol solution to obtain a mixed solution. Transfer the mixed solution to a 100mL polytetrafluoroethylene sealed autoclave, hydrothermally react at 190°C for 20h to obtain the reaction product, wash with ethanol and deionized water three times in turn after filtration, and dry at 70°C for 5h to prepare stannic acid Zinc Zn 2 SnO 4 powder;

[0041] (2) the Zn of step (1) 2 SnO 4 The powder was soaked in 10g / L potassium persulfate solution for 60min, washed 3 times with deionized water after taking it out, and dried at 60°C for 6h to obtain the zinc stannate photocatalyst OVs-Zn rich in oxygen vacancies 2 SnO 4 -1.

Embodiment 2

[0043] (1) 0.20g of SnCl 2 2H 2 O, 0.110g of ZnCl 2 , 0.12g of NaOH and 0.0040g of SDBS were dissolved in 80mL of 60% ethanol solution to obtain a mixed solution. The mixed solution was transferred to a 100mL polytetrafluoroethylene sealed autoclave, and the reaction product was obtained by hydrothermal reaction at 180°C for 18h. After filtration, it was washed with ethanol and deionized water for 3 times, and dried at 60°C for 7h to prepare stannic acid. Zinc Zn 2 SnO 4 powder;

[0044] (2) the Zn of step (1) 2 SnO 4 The powder was soaked in 7.5g / L potassium peroxodisulfate solution for 60min, washed 3 times with deionized water after taking it out, and dried at 70°C for 5h to obtain the zinc stannate photocatalyst OVs-Zn rich in oxygen vacancies 2 SnO 4 -2.

[0045] sample analysis

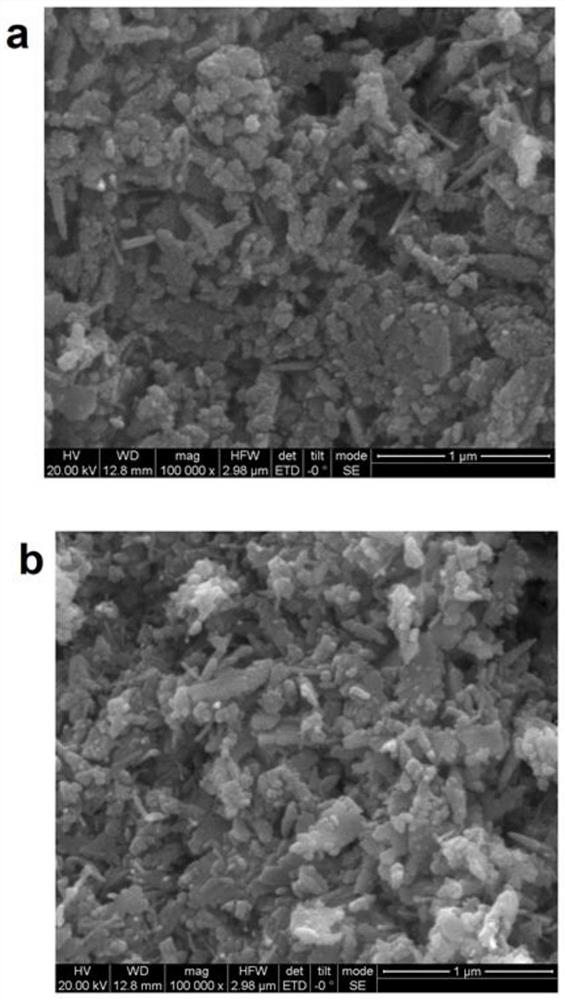

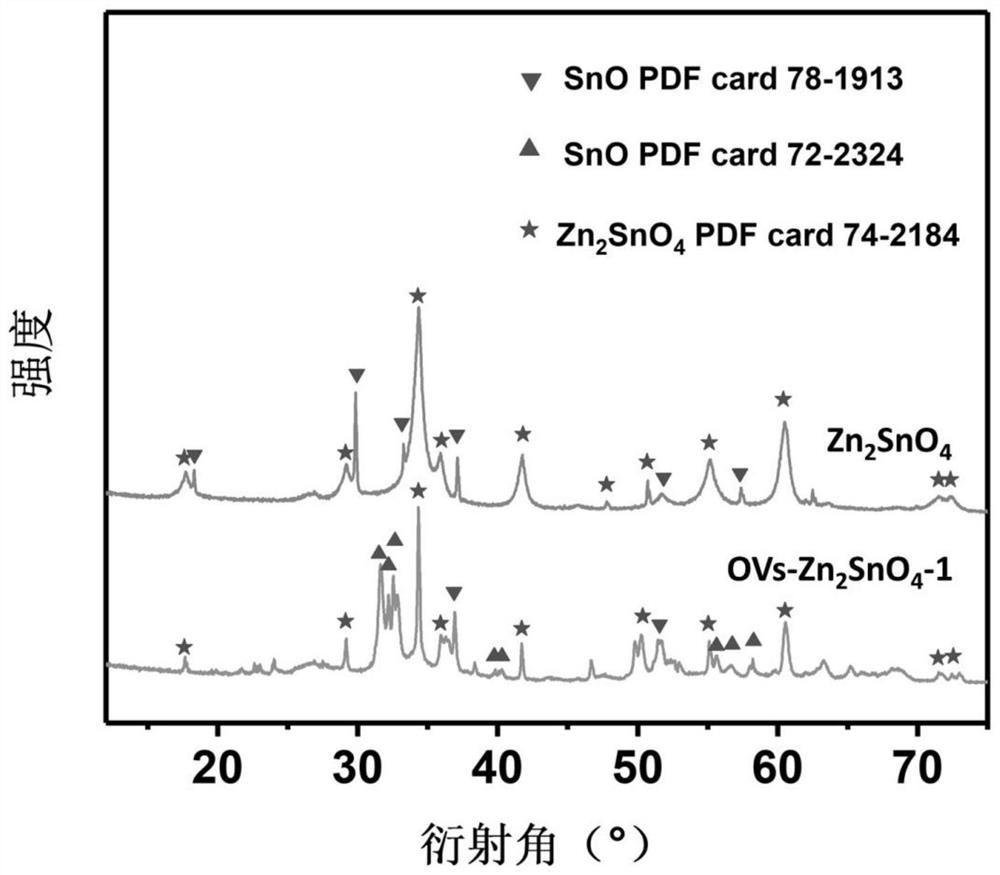

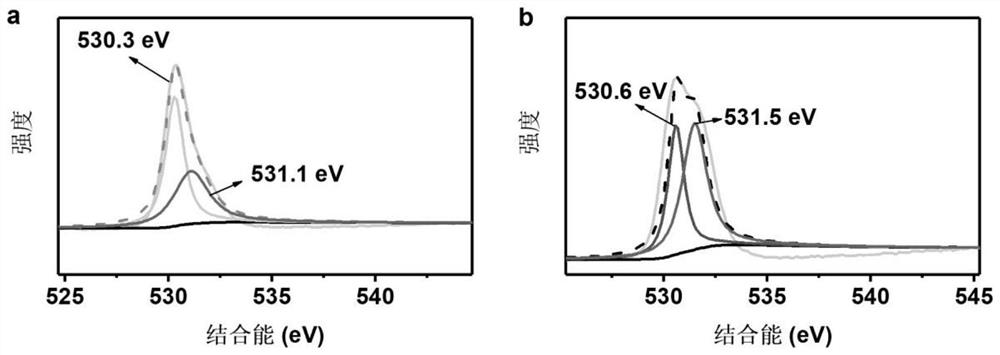

[0046] figure 1 For Zn in Example 1 2 SnO 4 and OVs-Zn 2 SnO 4 The scanning electron microscope picture of -1, where a is Zn 2 SnO 4 , b is OVs-Zn 2 SnO 4 -1, zinc stannate Zn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com