Modified suspended biological filler, preparation method thereof and sewage treatment method

A sewage treatment method and biological filler technology, applied in water/sludge/sewage treatment, aerobic and anaerobic process treatment, chemical instruments and methods, etc., can solve the problems of limited membrane filtration flux capacity and hydraulic shock load Poor ability, serious pollution and other problems, to achieve the effect of enhancing hydrophilicity and bio-affinity, improving surface properties, and high film-hanging capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

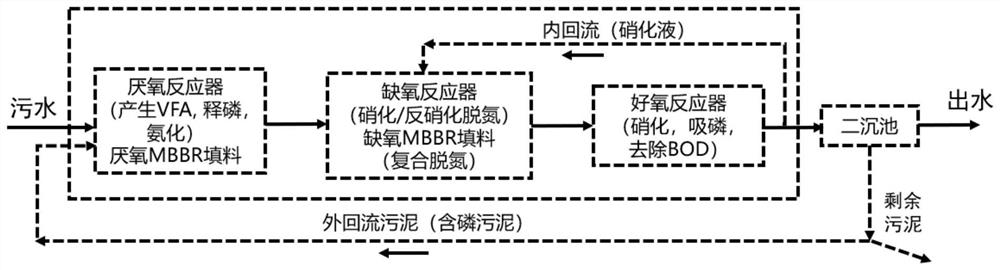

Method used

Image

Examples

Embodiment 1

[0044] Example 1 Preparation of modified suspended biological filler

[0045] 99 parts by weight of high-density polyethylene, 0.4 parts by weight of CaCO 3 Mix powder (particle size not greater than 15 μm), 0.4 parts by weight of talc powder (particle size not greater than 15 μm), 0.1 part by weight of ethoxylated alkylamine antistatic agent, and 0.1 part by weight of magnetic powder, and stir evenly in a mixer , and then put the mixture into the hopper of the injection molding machine, and extrude it through the filler mould.

[0046] The physical parameters of the filler prepared in this example are as follows: the material is HDPE, the structure material is a cylinder with 19 holes, the specification is Ф25×12mm, and the effective specific surface area of the filler is 620m 2 / m 3 , the density is 0.97~0.98g / cm 3 , bulk density is 140kg / m 3 .

Embodiment 2

[0047] Example 2 Preparation of modified suspended biological filler

[0048] 98.5 parts by weight of high-density polyethylene, 0.6 parts by weight of CaCO 3 Mix powder (particle size not greater than 10 μm), 0.6 parts by weight of talc powder (particle size not greater than 10 μm), 0.15 parts by weight of ethoxylated alkylamine antistatic agent, and 0.15 parts by weight of magnetic powder, and stir evenly in a mixer , and then put the mixture into the hopper of the injection molding machine, and extrude it through the filler mould.

[0049] The physical parameters of the filler prepared in this example are as follows: material HDPE, cylindrical 19-hole structure material, specification Ф25×12mm, effective specific surface area 620m 2 / m 3 , the density is 0.97~0.98g / cm 3 , bulk density is 140kg / m 3 .

Embodiment 3

[0050] Example 3 Preparation of modified suspended biological filler

[0051] 98 parts by weight of high-density polyethylene, 0.8 parts by weight of CaCO 3 Mix powder (particle size not greater than 10 μm), 0.8 parts by weight of talc powder (particle size not greater than 10 μm), 0.2 parts by weight of ethoxylated alkylamine antistatic agent, and 0.2 parts by weight of magnetic powder, and stir evenly in a mixer , and then put the mixture into the hopper of the injection molding machine, and extrude it through the filler mould.

[0052] The physical parameters of the filler prepared in this example are as follows: the material is HDPE, the structure material is a cylinder with 19 holes, the specification is Ф25×12mm, and the effective specific surface area of the filler is 620m 2 / m 3 , the density is 0.97~0.98g / cm 3 , bulk density is 140kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com