Low-cost comprehensive galvanizing wastewater treatment method

A technology that integrates wastewater and treatment methods. It is applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of high cost of chemicals and complex resource utilization, achieve good decolorization effect and improve oxidation reaction efficiency. , the effect of low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

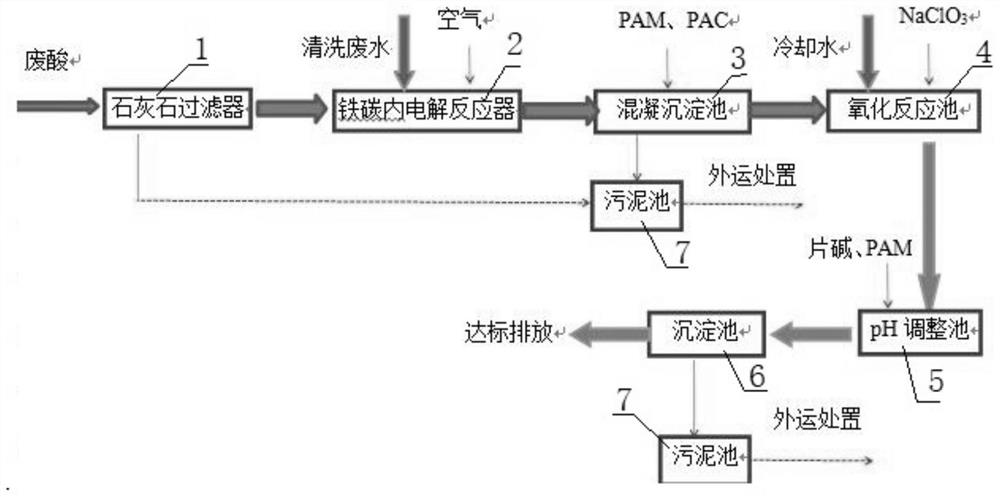

[0026] Example 1, such as figure 1 As shown, the low-cost galvanized comprehensive wastewater treatment system of the present invention is composed of limestone filter 1, iron-carbon inner electrolytic cell 2, coagulation sedimentation tank 3, oxidation reaction tank 4, pH adjustment tank 5, sedimentation tank 6 and sludge tank 7 composition.

[0027] The particle size of the limestone in the limestone filter 1 is 2-4mm. The outlet pipe of the limestone filter 1 is connected to the water inlet pipe of the iron-carbon inner electrolytic cell 2, and the iron-carbon inner electrolytic cell 2 is also provided with a cleaning liquid inlet pipe, and the outlet pipe of the iron-carbon inner electrolytic cell 2 is connected to the coagulation sedimentation tank 3 The water inlet pipe of the coagulation sedimentation tank 3 is connected with the water inlet pipe of the oxidation reaction tank 4. The water inlet pipe of the oxidation reaction tank 4 is also provided with a cooling wate...

Embodiment 2

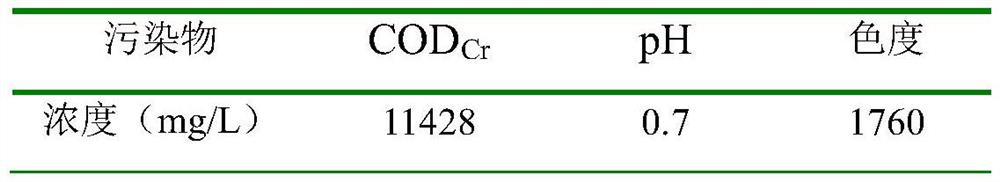

[0029] Waste acid influent water quality:

[0030]

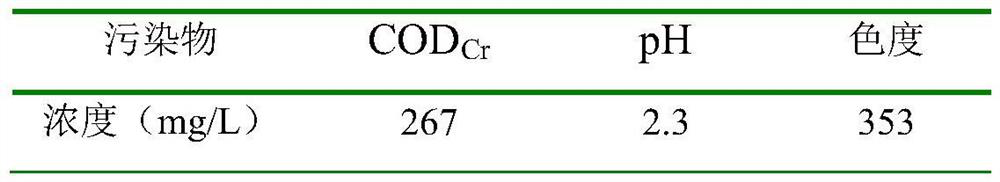

[0031] Cleaning wastewater influent water quality:

[0032]

[0033] Amount of waste acid 4m 3 / d, cleaning waste water is 10m 3 / d, cooling water is 20m 3 / d

[0034] The processing steps are as follows:

[0035] (1) Use a limestone filter to remove fine suspended matter, and at the same time, limestone reacts with acid to increase the pH value of wastewater to 2-3.

[0036] (2) The wastewater filtered by the limestone filter enters the iron-carbon inner electrolytic cell together with the plating piece cleaning wastewater, and iron flowers (also can be debris, which can be discarded in the factory processing process) are added in the iron-carbon inner electrolytic cell. The iron-carbon filler composed of iron flower) and granular activated carbon can increase the pH value of the wastewater from the iron-carbon internal electrolytic cell to 5-6.

[0037] (3) The wastewater from the iron-carbon internal electroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com