Marine drilling platform diesel engine waste heat recovery system with heat storage function

A technology for offshore drilling platforms and waste heat recovery systems, applied in heat storage equipment, steam generation methods using heat carriers, preheating, etc., can solve the problems of poor chemical stability of phase change heat storage materials, corrosion of heat exchanger pipes, and heat transfer problems. Poor capacity and other problems, to achieve the effect of improving energy utilization efficiency, saving floor space, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

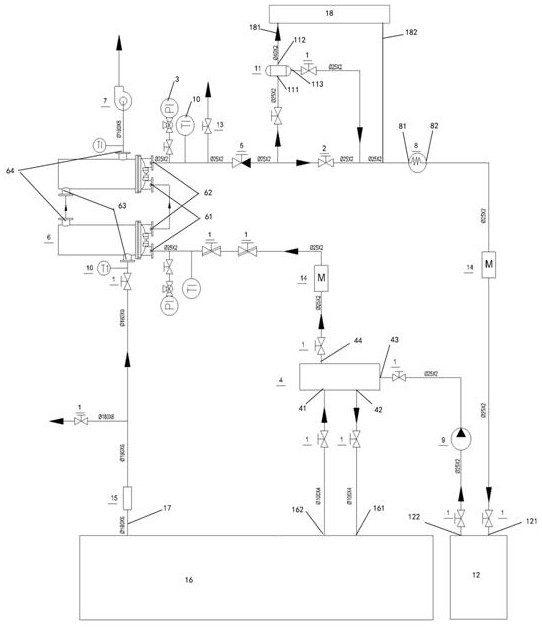

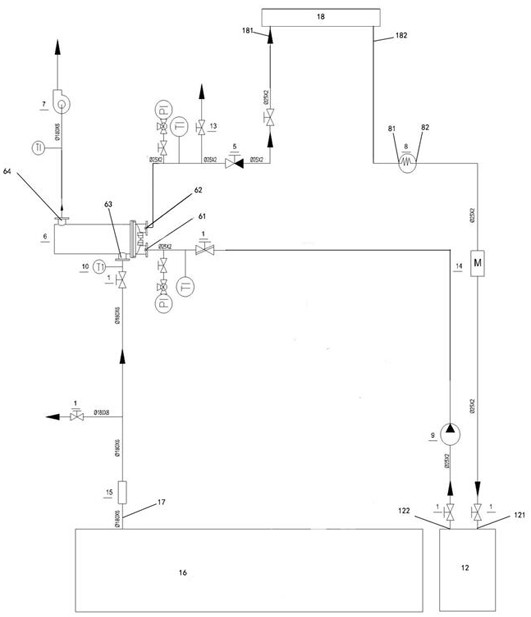

[0016] Embodiment one, such as figure 1 As shown, a diesel engine waste heat recovery system on an ocean drilling platform with heat storage function includes a diesel engine 16, a heat storage heat exchanger 6, an induced draft fan 7, a water tank 12, a jacket water preheating heat exchanger 4, a muffler 15, Pressure gauge 3, thermometer 10, flow meter 14, water pump 9, valve A2, shut-off valve 5 and other valves 1 used to control the on-off of the pipeline in the pipeline, wherein the heat storage heat exchanger 6 can be set as multiple units in series , in order to improve the efficiency of waste heat recovery, there are two in the figure; the thermometer 10 is a Vientiane bimetallic thermometer; the flowmeter 14 is a turbine flowmeter; the pressure gauge is a 3-digit marine pressure gauge; the valve 1 is a butterfly valve equipped with a metal hard seal.

[0017] Diesel engine 16 is provided with exhaust gas pipe 17, first cylinder jacket water inlet and outlet 161 and 162...

Embodiment 2

[0025] A diesel engine waste heat recovery system on an ocean drilling platform with heat storage function, comprising a diesel engine, a heat storage heat exchanger, a shut-off valve, steam-using equipment, a condenser, and a water tank.

[0026] The diesel engine is provided with an exhaust pipe, and the steam-using equipment is provided with a steam supply pipe and a water return pipe, and also includes a heat storage heat exchanger, a water tank, and a water pump. The heat storage heat exchanger is provided with a flue gas inlet and outlet and a second A circulating water inlet and outlet, the water tank is provided with water supply and return ports; the waste gas pipe is connected to the flue gas inlet; the water supply port is connected to the water pump, the water pump is connected to the first circulating water inlet, and the first circulating water outlet is connected to the The steam supply pipe is connected, and the water return pipe is connected with the water retu...

Embodiment 3

[0031] A method for recovering waste heat from a diesel engine on an ocean drilling platform with a heat storage function. First, the high-temperature flue gas flows through a heat storage heat exchanger, and the heat storage heat exchanger absorbs and stores the heat energy brought by the high-temperature flue gas, and then the circulating water flows through the jacket water Preheating heat exchanger, through the jacket water preheating heat exchanger, the heat energy of the jacket water is exchanged to the circulating water to preheat the circulating water, and finally the preheated circulating water is sent to the heat storage heat exchanger to absorb The heat energy stored in the heat exchanger further increases the temperature to generate wet steam, and then transports the wet steam to the steam-consuming equipment, and the circulating water circulated by the steam-consuming equipment returns to the water tank through the return pipe to complete the waste heat recovery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com