Double-layer polypropylene non-woven fabric membrane assembly and membrane pollution control method thereof

A polypropylene non-woven fabric and control method technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of increasing the content of suspended solids in effluent and improving the difficulty of water plant operation and management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

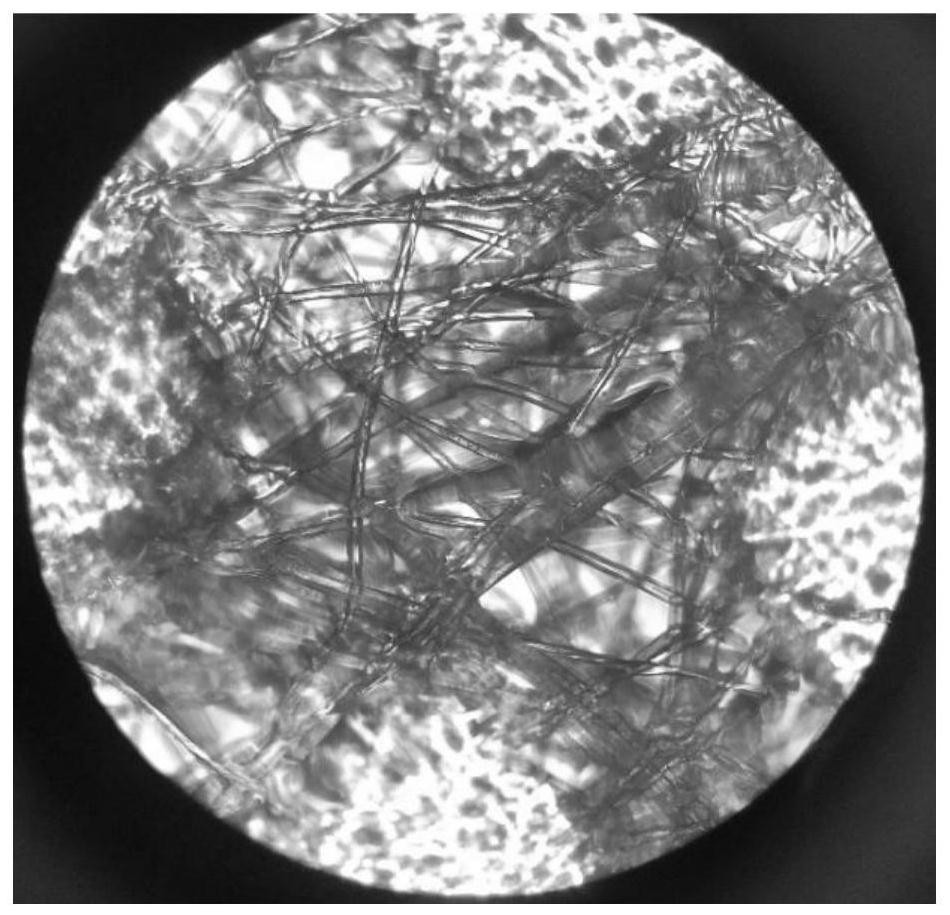

[0023] Membrane effluent suspended solids (SS) non-woven polypropylene membrane bilayer embodiment different flux of Example 1 and the content of the transmembrane pressure

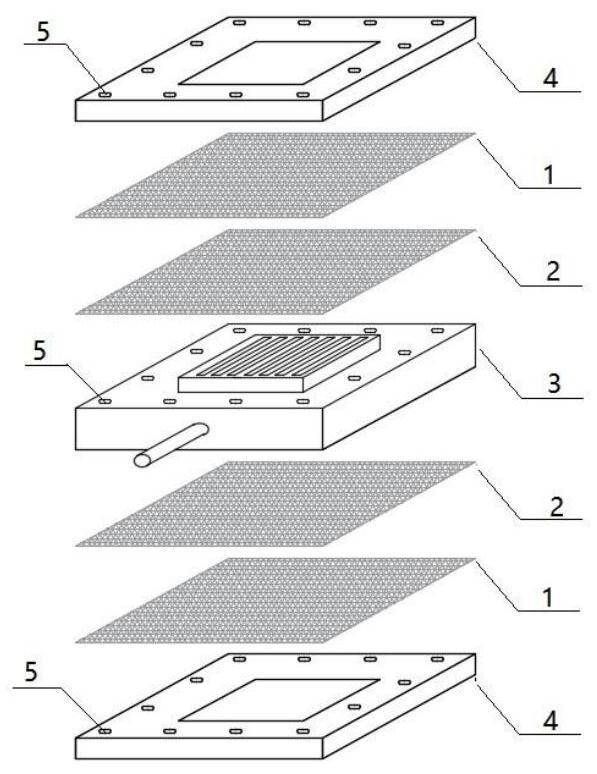

[0024] A two-layer nonwoven polypropylene membrane and membrane fouling control method using a first layer of polypropylene nonwoven fabric (1) a polypropylene nonwoven fabric and the second layer (2) made of a polypropylene non-bilayer as the nonwoven fabric filter membrane, in particular as membrane module assembly method: two double coated polypropylene nonwoven fabric (3) on both sides of the porous support frame, respectively, from two fixation panel frame (4) are respectively overlaid on the two double-layer polypropylene nonwoven fabric, a porous supporting frame (3) and two from the fixation panel frame (4) is provided with preformed holes (5), via a screw and a nut made of stainless steel prepared hole (5) the porous supporting frame (3), two-layer polypropylene nonwoven fabric (1,2) and two from the...

Embodiment 2

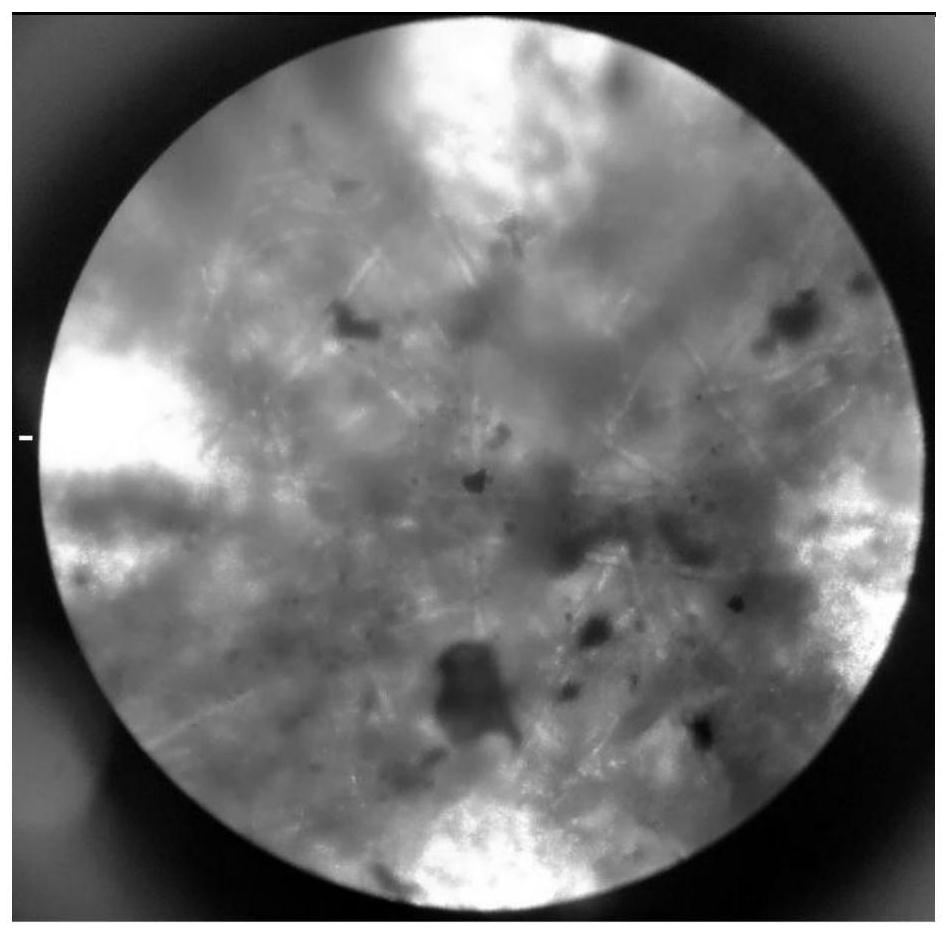

[0028] Example 2 aerobic membrane bilayer nonwoven polypropylene based membrane bioreactor wastewater treatment simulation

[0029] A two-layer nonwoven polypropylene membrane and membrane fouling control method using a first layer of polypropylene nonwoven fabric (1) a polypropylene nonwoven fabric and the second layer (2) made of a polypropylene non-bilayer as the nonwoven fabric filter membrane, in particular as membrane module assembly method: two double coated polypropylene nonwoven fabric (3) on both sides of the porous support frame, respectively, from two fixation panel frame (4) are respectively overlaid on the two double-layer polypropylene nonwoven fabric, a porous supporting frame (3) and two from the fixation panel frame (4) is provided with preformed holes (5), via a screw and a nut made of stainless steel prepared hole (5) the porous supporting frame (3), two-layer polypropylene nonwoven fabric (1,2) and two from the fixation panel frame (4) are pressed and fixed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com