Micro-reaction equipment and method for preparing 2-nitro-4-methylsulfonyl toluene

A methylsulfonyltoluene and microreaction technology, which is applied in the field of 2-nitro-4-methylsulfonyltoluene synthesis, can solve the problems of poor mass transfer, poor heat transfer effect, small single-channel processing capacity, uneven material mixing, and the like, To achieve the effect of short material residence time, large single-channel processing capacity, and increased mass transfer surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

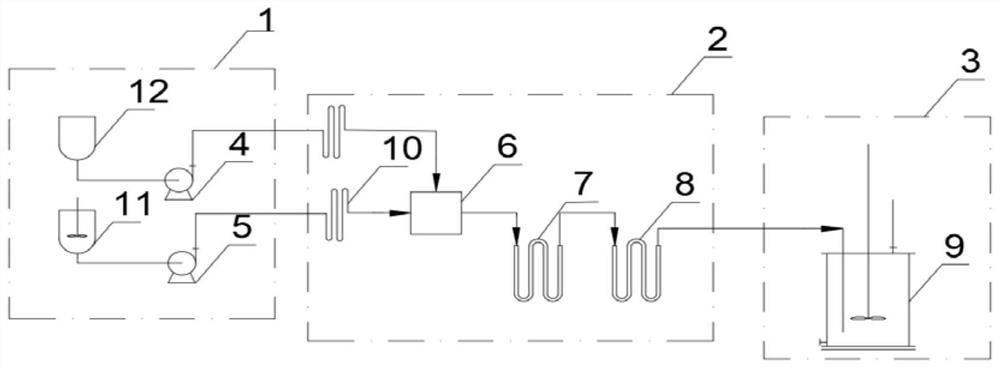

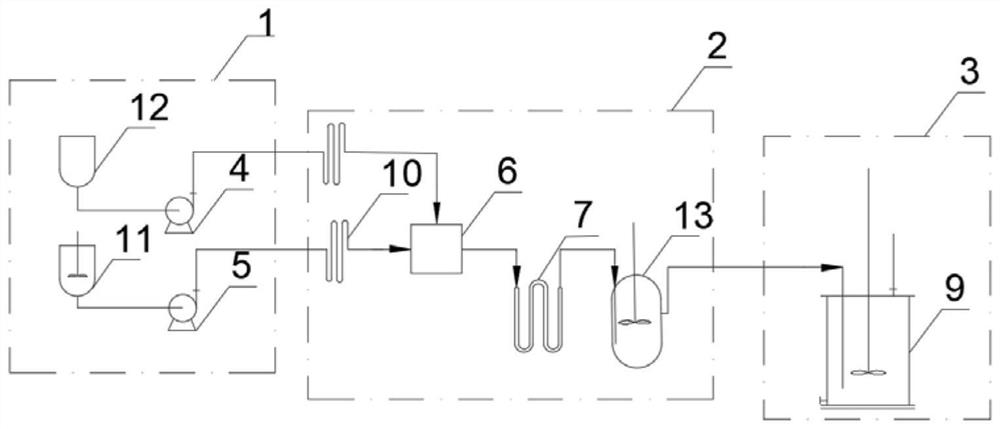

[0048] The present invention also provides a method for synthesizing 2-nitro-4-methylsulfonyltoluene, which adopts the equipment in the above scheme to complete, and the method comprises the following steps:

[0049] (1) p-methylsulfonyltoluene and concentrated sulfuric acid are mixed and dissolved in a molar ratio of 1:2-10 to prepare a raw material solution.

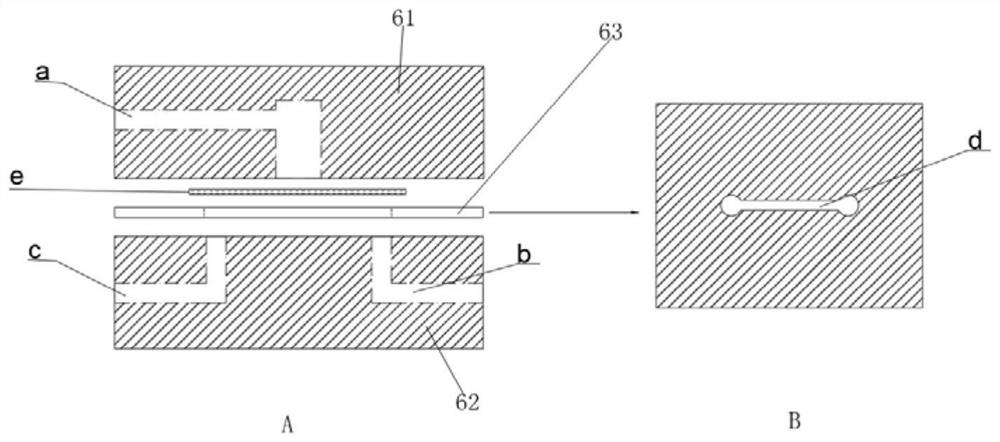

[0050] (2) The advection pump 5 transports the raw material liquid to the continuous phase inlet of the microreactor 6, and the concentrated nitric acid of the dispersed phase is transported to the disperse phase inlet of the microreactor 6 by the advection pump 4, and is dispersed into tiny particles through the microreactor 6 microdispersion medium membrane After the droplets are mixed with the raw material liquid and react.

[0051] (3) The reaction solution enters the material collection tank 9 through the first-level pipeline reactor 7, and the second-level pipeline reactor 8 or the stirred tank reactor 13 after t...

Embodiment 1

[0058] Add p-methylsulfonyl toluene and concentrated sulfuric acid to the raw material tank, stir fully to dissolve p-methylsulfonyl toluene and mix it evenly, turn on the temperature-controlled water bath, control the reaction temperature of the micro-reactor and the primary pipeline reactor to 20°C, and control The reaction temperature of the secondary pipeline reactor is 50°C. After the temperature is stabilized, the advection pump is turned on to control the feed molar ratio of p-methylsulfonyltoluene, concentrated nitric acid and concentrated sulfuric acid to be 1:1.1:5, and the mass of concentrated sulfuric acid is 1:1.1:5. The fraction is 98%, the mass fraction of nitric acid is 65%, the total feed flow rate is 150ml / min, the dispersion medium of the microreactor is a 1um microfiltration membrane, the system pressure is 0.5mpa during the reaction, and water is added to the reaction solution after the reaction. The precipitated solid was filtered, washed and dried to obta...

Embodiment 2

[0060] Add p-methylsulfonyltoluene and concentrated sulfuric acid to the raw material tank, stir fully to dissolve p-methylsulfonyltoluene and mix evenly, turn on the temperature-controlled water bath, control the reaction temperature of the micro-reactor and the first-stage pipeline reactor to 30°C, and control The reaction temperature of the secondary pipeline reactor is 50°C. After the temperature is stabilized, the advection pump is turned on to control the feed molar ratio of p-methylsulfonyltoluene, concentrated nitric acid and concentrated sulfuric acid to be 1:1.1:5, and the mass of concentrated sulfuric acid is 1:1.1:5. The fraction is 98%, the mass fraction of nitric acid is 70%, the total feed flow rate is 120ml / min, the dispersion medium of the microreactor is a 1um microfiltration membrane, the system pressure is 0.2mpa during the reaction, and water is added to the reaction solution after the reaction. The solid was precipitated, and after suction filtration, wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com