Method for synthesizing methoxyamine hydrochloride

A technology of methoxyamine hydrochloride and mixed solution, which is applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, etc., can solve problems such as cumbersome operation, and achieve The effect of uniform reaction, low emission, and reduced investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

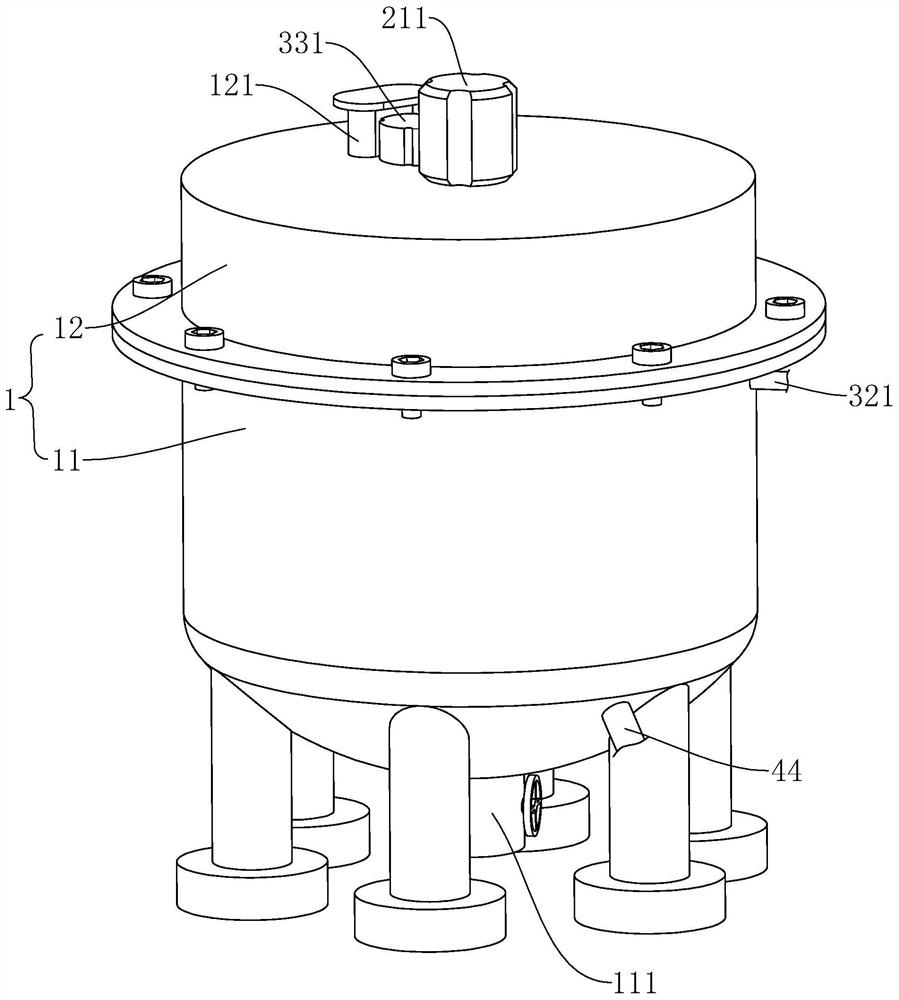

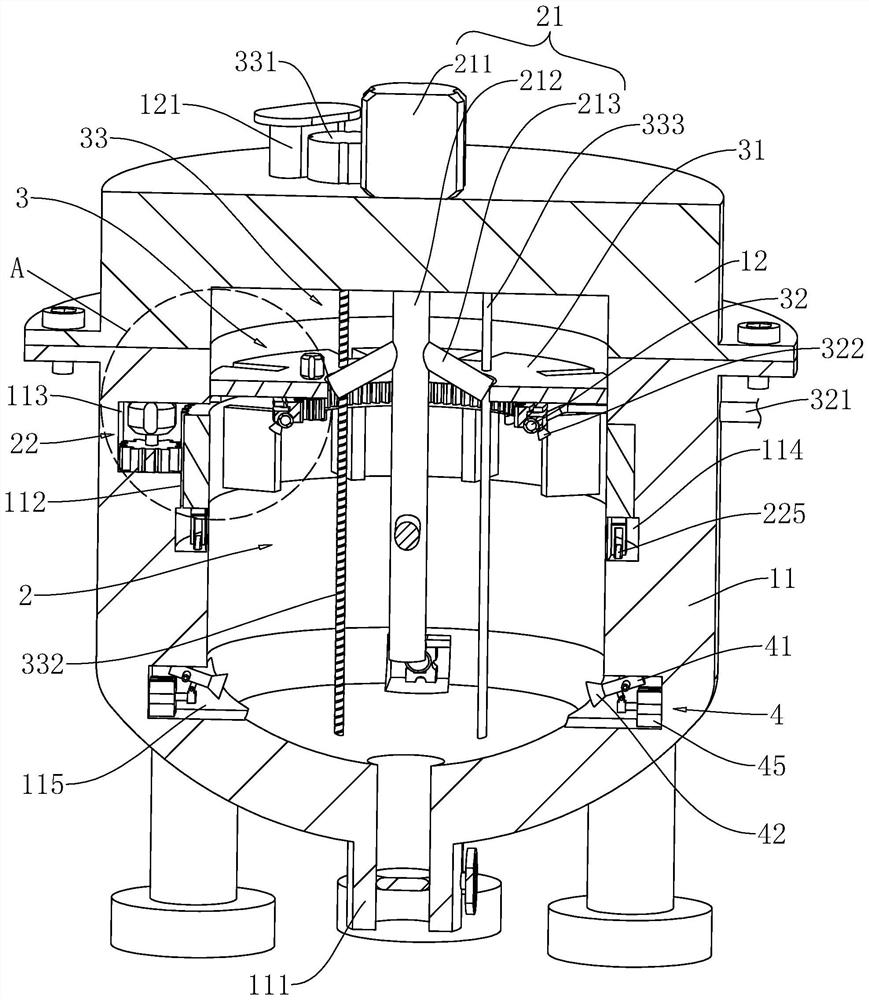

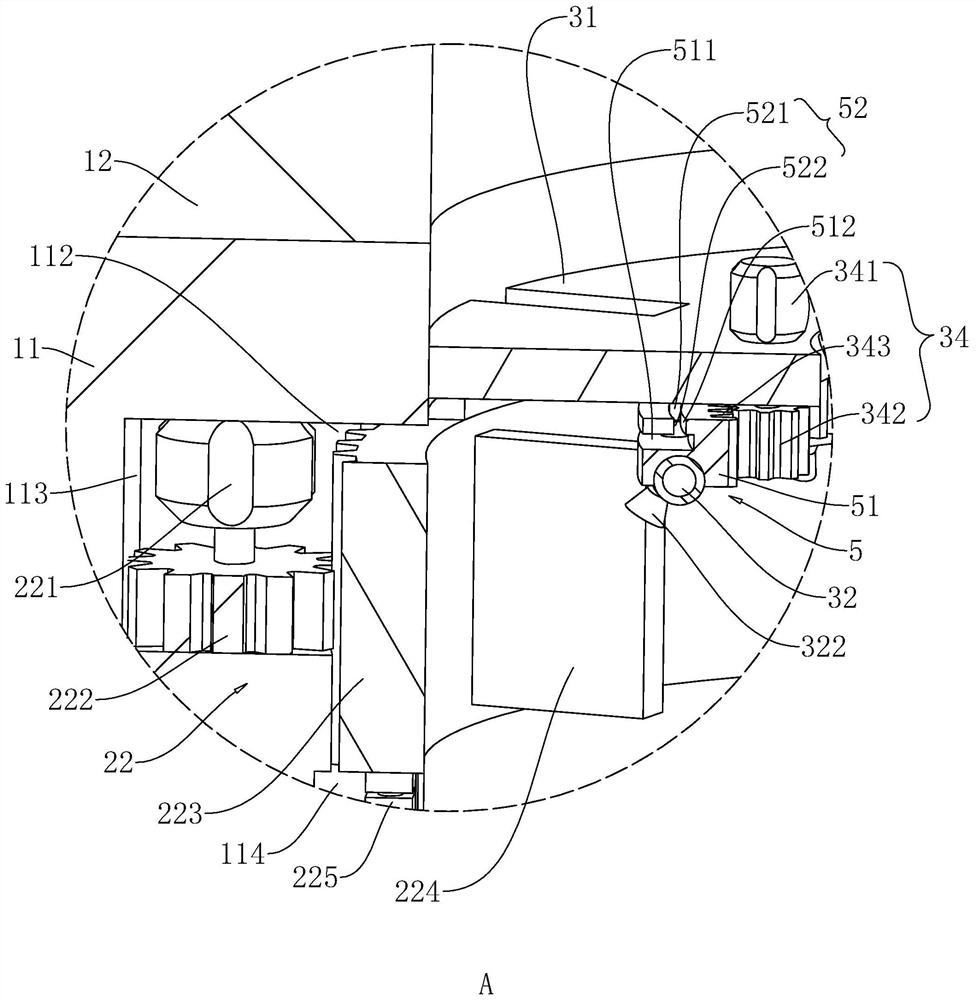

[0041] The following is attached Figure 1-4 The application is described in further detail.

[0042] The embodiment of the present application discloses a method for synthesizing methoxyamine hydrochloride. refer to figure 1 , figure 2 , the method for synthesizing methoxyamine hydrochloride comprises the steps:

[0043] S1. Add water and sodium hydroxide to reactor 1, stir and dissolve at room temperature, then add butanone oxime and a phase transfer catalyst, wherein the phase transfer catalyst is PEG500;

[0044] S2. Cool the inside of the reactor 1 to 0-15°C, specifically, to 5°C, and add a methylating reagent to the reactor 1, wherein the methylating reagent is dimethyl sulfate;

[0045] S3. After the addition is completed, react at a temperature of 10°C for 4 hours, then cool to below 5°C and stand to separate layers to obtain an organic layer and a water layer, distill the water layer and collect the distillate, then combine the oil layer and the distillate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com