Biosynthesis method of starch

A technology of amylose and synthetic starch, which is applied in the direction of transferase and fermentation, can solve the problems of lack of technology and methods, and achieve the effect of reducing agricultural land and shortening the synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

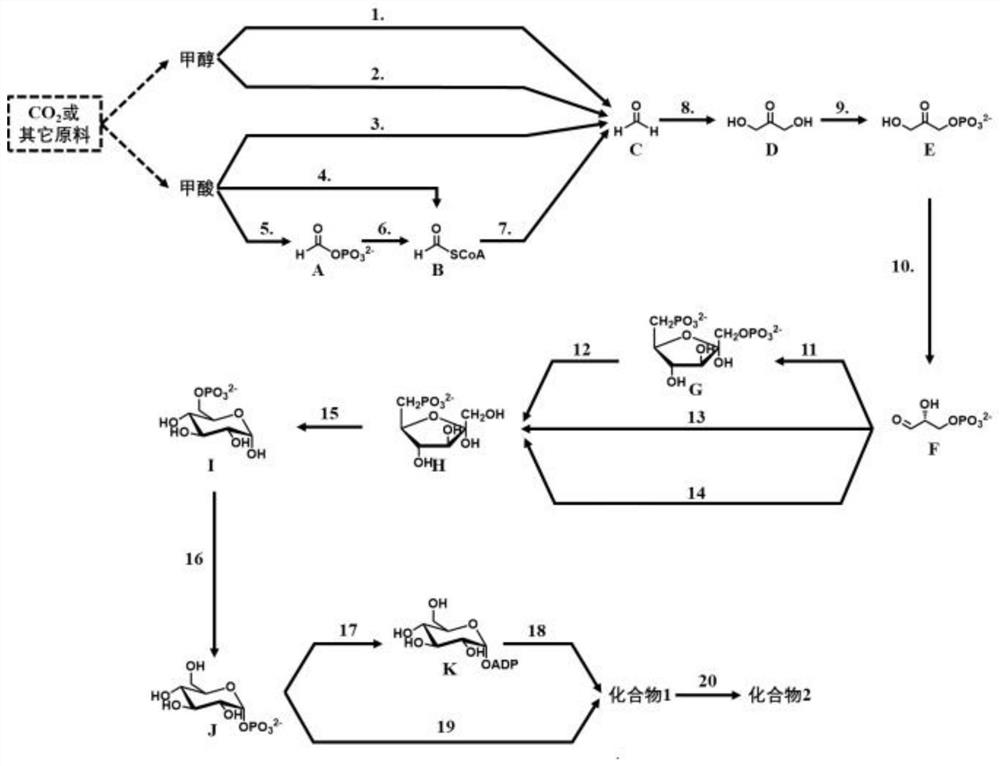

[0172] Embodiment 1 is from formic acid or methyl alcohol to the synthesis of compound C i.e. formaldehyde

[0173] There are five pathways for the conversion of formic acid or methanol to compound C, namely: pathway 1 (from methanol to formaldehyde), pathway 2 (from methanol to formaldehyde), pathway 3 (from formic acid to formaldehyde), pathways 4-7 (from formate to formyl-CoA to formaldehyde), and pathway 5-6-7 (from formate to formyl phosphate to formyl-CoA to formaldehyde) (reaction numbers see figure 1 ). Catalysts (ie, enzymes) that can catalyze each chemical reaction of each pathway are first selected (see Table 1), but enzymes with corresponding catalytic functions are not limited to those listed in Table 1. Then different catalysts are combined according to the route to establish a corresponding reaction system, and after a period of reaction, the production of formaldehyde is detected.

[0174] The output of compound C was detected according to the following metho...

Embodiment 2

[0180] Embodiment 2 is from methyl alcohol to the synthesis of compound D i.e. dihydroxyacetone

[0181] The synthesis from methanol to compound D can be achieved through the following routes:

[0182] Route 2-8: The reaction system is Hepes buffer 100mM at pH 7.5, NaCl 100mM, Mg 2+ 5mM, Zn 2+ 10μM, AOX 1U / mL, CAT 300U / mL, methanol 20mM, FLS 5mg / mL; after 2 hours of reaction, the yield of compound D was 2.1mM.

[0183] The detection method of compound D: 5mM dilute sulfuric acid as mobile phase, HX87 column (Bio-Rad, Aminex@, 300mm×78mm), flow rate 0.6mL / min, sample volume 10μL / needle, calculate compound D according to DHA standard curve Yield. Figure 4 The yields of pathways 2-8 from methanol to compound D are shown in .

Embodiment 3

[0184] Embodiment 3 is from formaldehyde to the synthesis of compound D i.e. dihydroxyacetone

[0185] The synthesis from formaldehyde to compound D can be realized through the following routes:

[0186] Route 8: The reaction system is Hepes buffer 100mM at pH 7.5, NaCl 100mM, Mg 2+ 5mM, Zn 2+ 10 μM, formaldehyde 25 mM, TPP 0.5 mM, FLS (source: Pseudomonasputida) 10 mg / mL; react for 2 hours, and use the method in Example 2 to detect compound D. Results: The yield of compound D synthesized by formaldehyde lyase FLS is 7.092 mM.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap