Zinc-based electrode capable of delaying nucleation of zinc dendrites as well as preparation method and application of zinc-based electrode

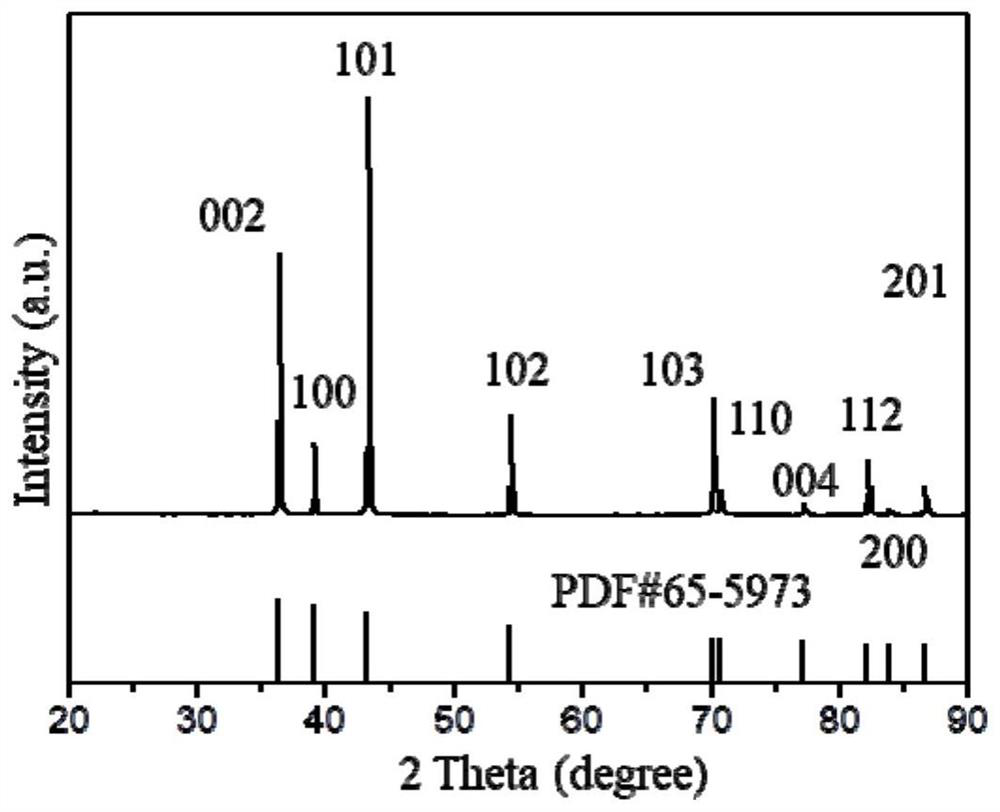

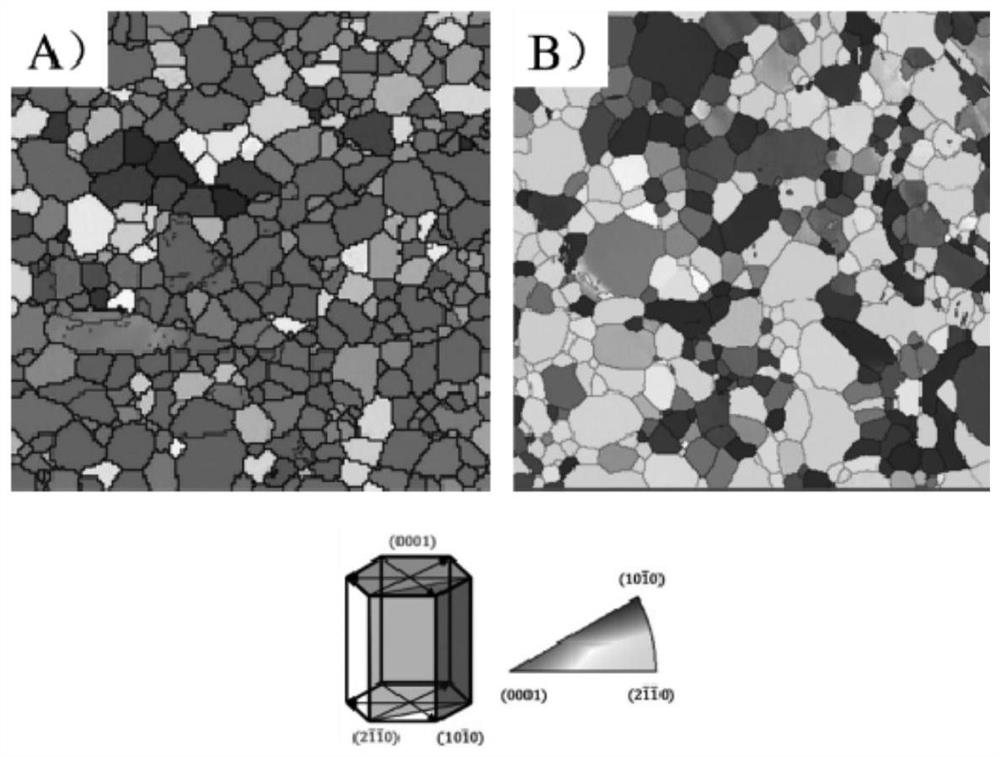

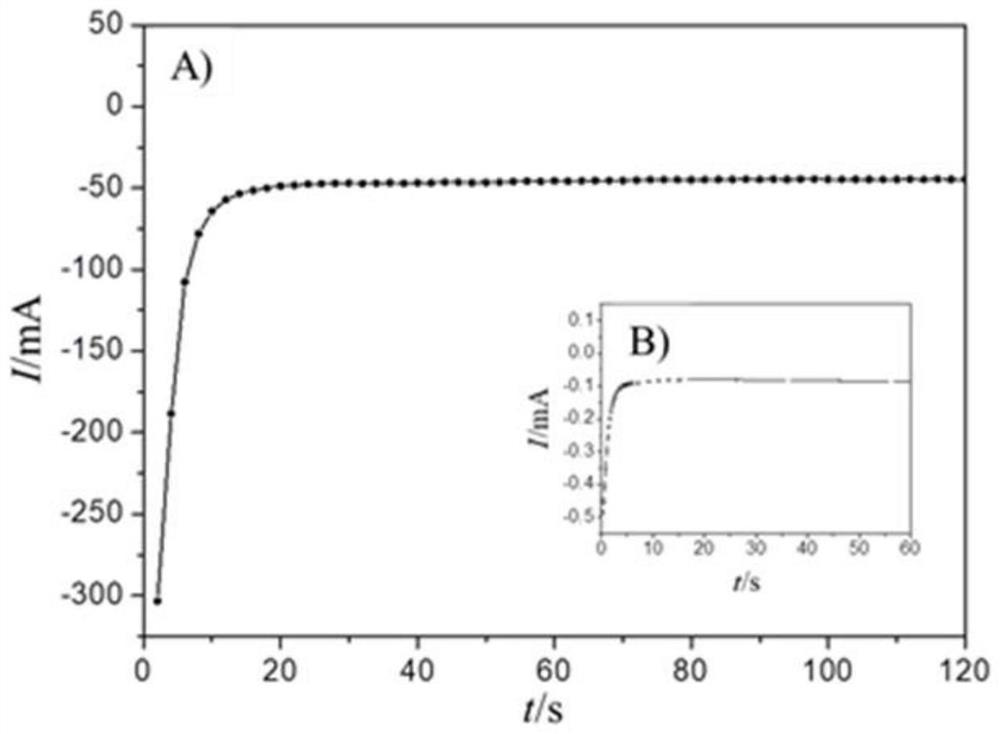

A zinc dendrite, zinc-based technology, applied in electrode manufacturing, electrode rolling/calendering, battery electrodes, etc., can solve the problem of low lattice mismatch between zinc-based and substrate, water-based zinc-ion batteries Poor electrode stability, short battery life and other issues, to avoid internal short-circuit battery failure, delay the growth of dendrite orientation, and not easy to short-circuit the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A preferred embodiment of the present invention provides a method for preparing a zinc-based electrode material, the method specifically comprising:

[0041] Use commercially available zinc ingots, which are pure zinc (purity above 95%) polycrystalline or binary or multi-element zinc alloys with a zinc content (mass fraction) above 85% or zinc and zinc oxide composite materials, after a constant temperature of 100°C Under the condition of heat preservation for 3 hours, adjust the rolling temperature of the mechanical rolling mill to 100°C or slightly higher than 100°C, preheat to the rolling temperature, adjust the relative height of the rollers of the rolling mill, and use the hot (warm) rolling plastic deformation processing method in the Single-pass or reciprocating multi-pass rolling at a temperature of 100°C to form a zinc plate, and keep the rolling plate and rolling direction unchanged during the rolling process. At the same time, by adjusting the relative height...

Embodiment 1

[0050] This embodiment 1 provides a battery, which is prepared by the following steps:

[0051] S1: heat a commercially available pure zinc plate with a purity of more than 95% in a vacuum oven at a constant temperature of 100°C for 3 hours;

[0052] S2: Adjust the rolling temperature of the hot rolling mill to 100°C, and start hot rolling (warm rolling) the above-mentioned thermal insulation zinc plate after the surface temperature of the roll reaches the preset temperature;

[0053] S3: Control the deformation of the zinc ingot by adjusting the height of the roll to an appropriate value, avoid edge cracks due to excessive deformation during the rolling process of the zinc plate, and keep the zinc plate and the rolling direction unchanged during the rolling process;

[0054] S4: In order to avoid the thermal effect caused by mechanical cutting to change the physical and chemical properties of the material, the high-pressure water jet cutting machine is used as a cold working ...

Embodiment 2

[0059] This embodiment 2 provides a battery, which is prepared by the following steps:

[0060] S1: heat a commercially available pure zinc column with a purity of more than 95% in a vacuum oven at a constant temperature of 100°C for 3 hours;

[0061] S2: Adjust the temperature of the metal drawing machine to 100°C. When the temperature reaches the preset temperature, start the drawing experiment of the above-mentioned thermal insulation zinc column;

[0062] S3: By uniformly controlling the deformation of the zinc ingot, avoiding the breakage of the zinc column due to excessive deformation during the drawing process, while keeping the zinc column and the drawing direction unchanged during the drawing process;

[0063] S4: In order to avoid changing the physical and chemical properties of the material due to the thermal effect caused by mechanical cutting, a high-pressure water jet cutting machine is used as a cold processing method to cut the drawn zinc column or zinc wire in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com