Three-dimensional carbon structure loaded GaN catalyst and preparation method thereof

A carbon structure and catalyst technology, applied in the field of three-dimensional carbon structure supported gallium nitride catalyst and its preparation, can solve the problems of low catalytic efficiency, low activity of non-precious metal catalyst, poor stability of non-precious metal catalyst, etc. The effect of improving the performance of electrocatalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

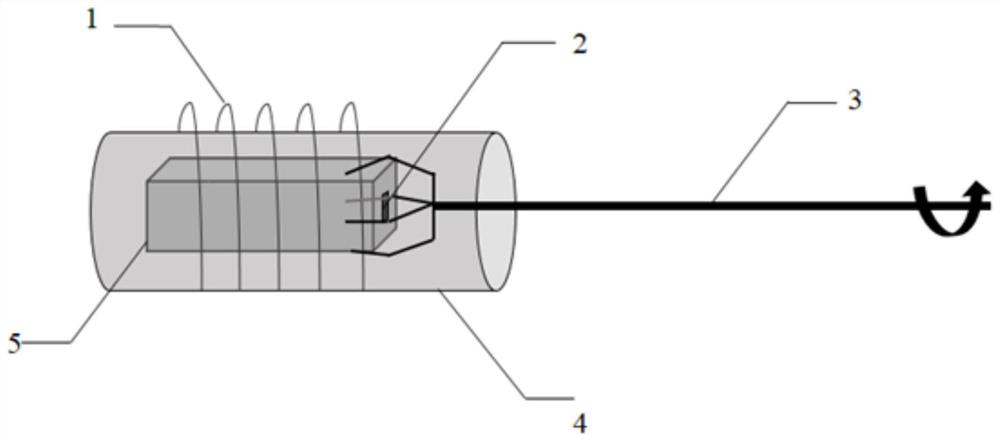

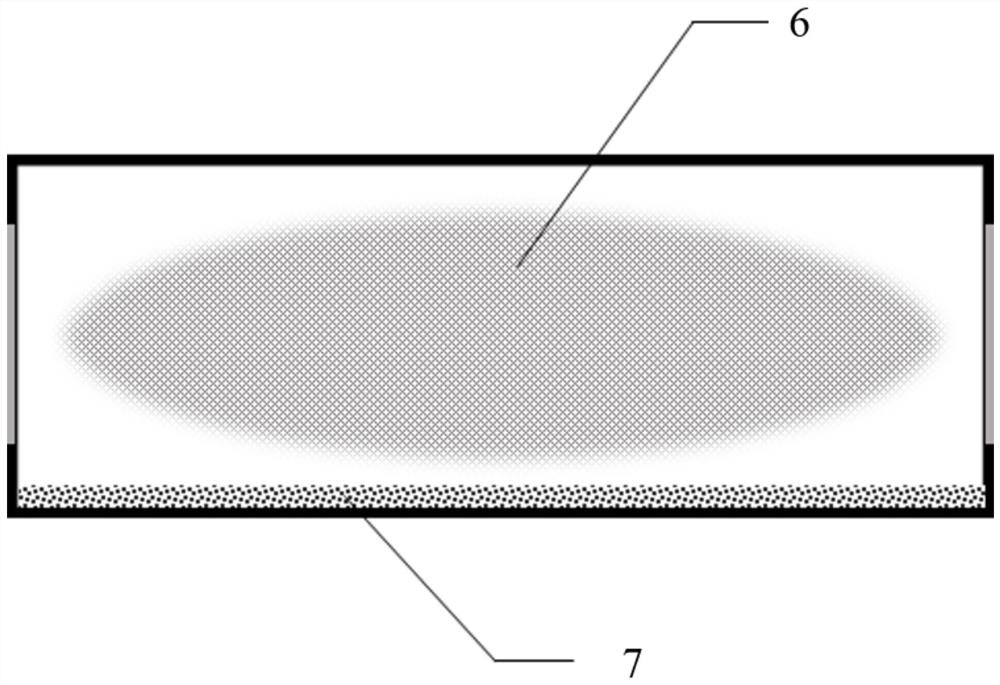

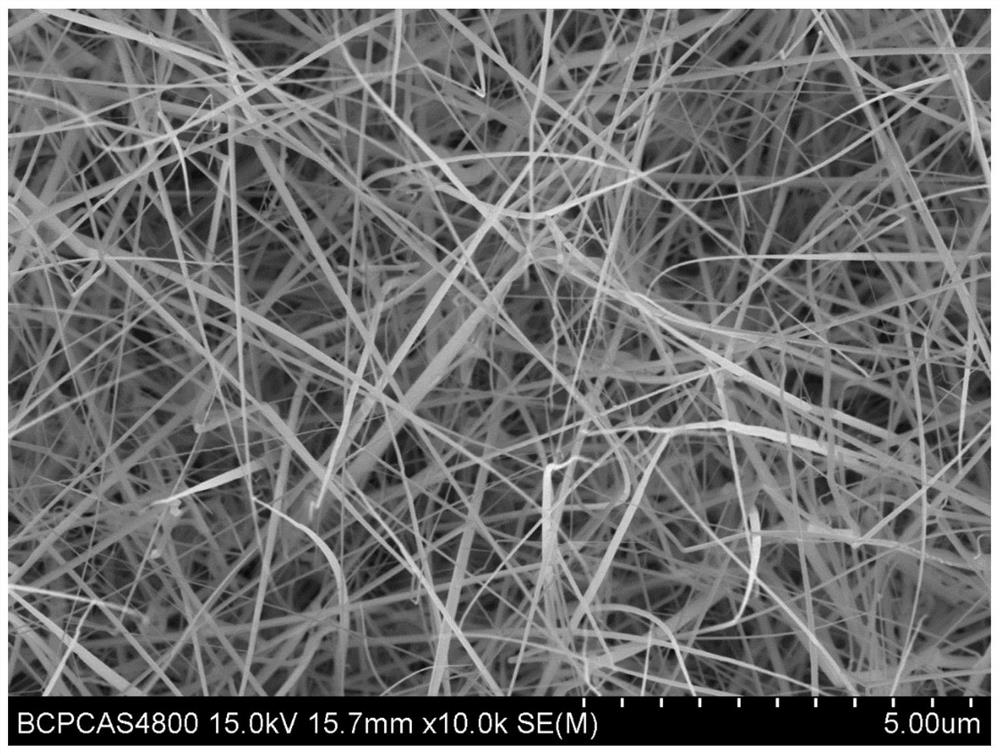

[0028] Weigh 0.5g of carbon nanotubes, 0.5g of graphene, 0.5g of fullerene, and 1g of carbon black to make a uniformly mixed powder, add 10g of 10wt% nitric acid solution to the powder, and stir at 60°C for 5 hours , the resulting mixture was washed with water and suction-filtered and dried at 60°C for 5 hours, and the dried product was ball-milled at 250rpm for 1 hour to obtain a three-dimensional carbon structure powder; the powder was placed in a rotatable ceramic crucible of a plasma-enhanced chemical vapor deposition system, The thickness of the powder is 1mm, the rotation speed of the crucible is 1rpm, and N 2 The gas flow rate is 5 sccm, the radio frequency power is 150W, and the holding temperature is 100°C, and plasma treatment is carried out for 1 hour; 1 g of gallium oxide powder and 0.5 g of activated carbon powder are weighed to prepare a mixed powder, and placed in a microwave plasma chemical vapor deposition system In the crucible, the pre-prepared surface sputt...

Embodiment 2

[0030] Just change the ratio of the three-dimensional carbon structure raw material in step 1 to: 1.5g of carbon nanotubes, 1.5g of graphene, 1.5g of fullerene, and 10g of carbon black to make a uniformly mixed powder, and other conditions remain unchanged, the same as in the embodiment 1. The mass activity of the prepared three-dimensional carbon structure-supported GaN catalyst is 87.4 mA / mg, and its mass activity decays by 23.9% after 10,000 cycles of aging test.

Embodiment 3

[0032] Just change the process in step 1 to: add 10g of 10wt% nitric acid solution to the powder, stir at 80°C for 10 hours, wash the resulting mixture with water and suction filter and dry at 80°C for 10 hours, and ball mill the dried product at 400rpm for 2 hours, Other conditions remain the same, as in Example 1, the prepared three-dimensional carbon structure-supported GaN catalyst has a mass activity of 90 mA / mg, and after 10,000 cycles of aging test, its mass activity decays to 24.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com