Radix morindae officinalis processed product oligosaccharide composition, and preparation method and application thereof

A composition and technology of Morinda officinalis salt are applied in the field of oligosaccharide composition of processed Morinda officinalis and its preparation, and can solve the problems of restricting the application of processed Morinda officinalis products and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] The preparation of embodiment 1 Morinda officinalis processed product oligosaccharide

[0097] 1. Preparation of oligosaccharides from various processed products of Morinda officinalis

[0098] 1.1 Preparation of Raw Morinda officinalis and processed products of Morinda officinalis

[0099] Take fresh Morinda officinalis, remove the soil and fibrous roots, remove the wood core, and dry at 60°C to obtain raw Morinda officinalis;

[0100] Take 1000g of raw Morinda officinalis, cut it into short sections of 1-1.5cm, add 700mL of water and moisten it for 4 hours until the water is completely absorbed, and steam it in a stainless steel pot at 160°C for 4h, take it out, let it cool, dry at 60°C, and sieve Remove the debris, and you can get the processed product of Morinda officinalis: Morinda officinalis meat;

[0101] Take 1000g of raw Morinda officinalis, cut it into short sections of 1-1.5cm, add 700mL of saline with 3% of the medicinal material, moisten it for 4 hours u...

Embodiment 2

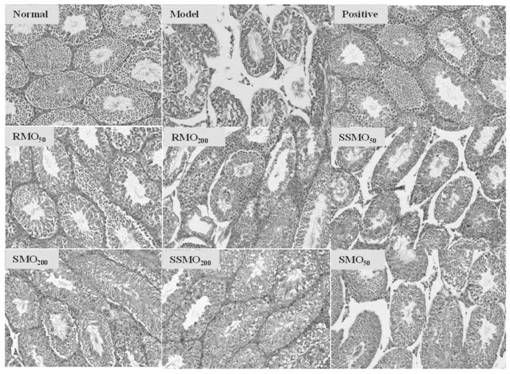

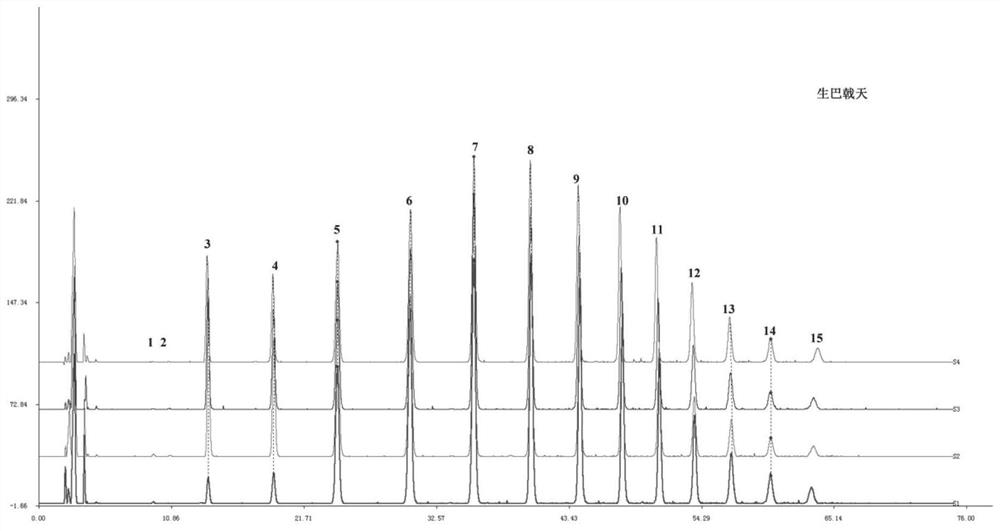

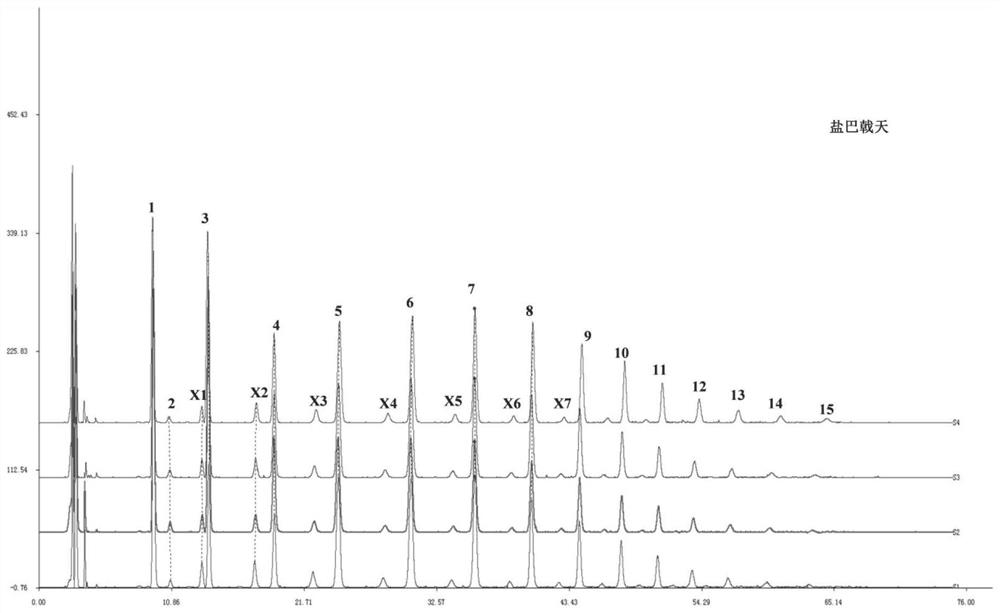

[0108] Example 2 Determination of oligosaccharide components of raw Morinda officinalis and processed products of Morinda officinalis

[0109] Take 0.1 g of oligosaccharides of raw Morinda officinalis, Morinda officinalis meat, and Morinda officinalis salt, accurately weigh the weight, add 60% acetonitrile to dissolve and dilute to 10 mL, shake well, pass through a 0.22 μm microporous membrane, as Samples to be tested; 6 kinds of inulin-type oligosaccharides were taken as reference substances: D-fructose, D(+)-anhydroglucose, sucrose, 1-kestose, nassose and 1 F - Fructofuranosyl Nessose, accurately weighed, placed in a measuring bottle, added 60% volume fraction of acetonitrile to dissolve and set the volume to 10mL, shake the solution, and make each 1mL containing D-fructose 1.378mg, D- (+)-Anhydrous Glucose 0.828mg, Sucrose 1.210mg, 1-Kestose 0.832mg, Nessose 1.280mg, 1 F -The mixed reference substance solution of 1.658 mg of fructofuranosyl Nessose.

[0110] Both the test...

Embodiment 3

[0112] Example 3 Separation and identification of oligosaccharide component X in Morinda officinalis processed products

[0113] 1. Separation of oligosaccharide component X in Morinda officinalis processed products

[0114] 1.1 Preparation of acetylated oligosaccharides from Morinda officinalis processed products

[0115] (1) Get 15g of oligosaccharides of Morinda officinalis Morinda officinalis processed product salt Morinda officinalis of embodiment 1, join in 500mL dry round bottom flask, add pyridine 200mL, stir at room temperature to make oligosaccharides all dissolve, then add acetic anhydride 200mL, Shake well and react at room temperature for 36h. The mixture was concentrated under reduced pressure to obtain acetylated oligosaccharide extract.

[0116] (2) Take 25g of Morinda officinalis processed product oligosaccharide acetylate extract, add appropriate amount of methanol to dissolve it completely, add 50g of 100-200 mesh silica gel and stir, make the silica gel e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com