Super-hydrophobic modification method of nanocellulose

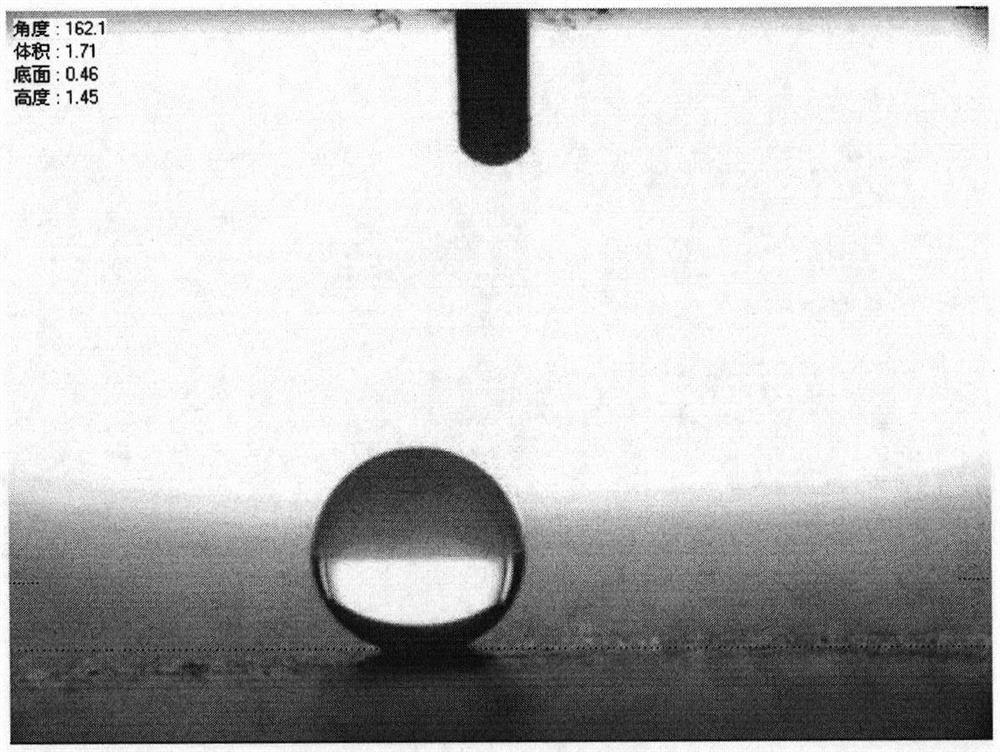

A technology of nanocellulose and superhydrophobic modification, which is applied in the field of superhydrophobic modification of nanocellulose, can solve the problems of limiting the development speed of nanocellulose and decreasing the stiffness of nanocellulose materials, and achieves enhanced superhydrophobicity, The effect of strengthening long hydrophobic chains and loose structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of nanocellulose: Weigh 30g of dry bleached sulfate hardwood pulp, soak it in 5% NaOH solution for 12 hours, carry out dispersing (20000r), PFI beating (4000r), washing with distilled water and centrifuging three times (8000r) / min, 20min), freeze-dried for 48h. 5 g of the freeze-dried pulp sample was weighed, and 95 ml of distilled water was added to obtain a cellulose suspension with a concentration of 5%. 0.5 g of NaBr, 0.06 g of TEMPO, and 20 mmol of NaClO were added in sequence, and 0.1 mol / L of HCl and 0.1 mol / L of NaOH were added dropwise to control the pH of the reaction system to remain constant at 10. The slurry sample was then placed into a tank-type ultrasonic wave for ultrasonic vibration treatment for 3 hours, ethanol was added to terminate the reaction, centrifuged and washed three times (8000 r / min, 15 min), and freeze-dried to obtain nanocellulose powder;

[0027] (2) Preparation of hydrophobic nanocellulose particles: weigh 2g of nanoc...

Embodiment 2

[0030] (1) Preparation of nanocellulose: Weigh 30g of dry bleached sulfate hardwood pulp, soak it in 8% NaOH solution for 12 hours, carry out dispersing (20000r), PFI beating (4000r), washing with distilled water and centrifuging three times (8000r) / min, 20min), freeze-dried for 48h. 5 g of the freeze-dried pulp sample was weighed, and 95 ml of distilled water was added to obtain a cellulose suspension with a concentration of 5%. 0.5 g of NaBr, 0.06 g of TEMPO, and 40 mmol of NaClO were successively added, and 0.1 mol / L of HCl and 0.1 mol / L of NaOH were added dropwise to control the pH of the reaction system to remain constant at 10. The slurry sample was then placed into a tank-type ultrasonic wave for ultrasonic vibration treatment for 3 hours, ethanol was added to terminate the reaction, centrifuged and washed three times (8000 r / min, 15 min), and freeze-dried to obtain nanocellulose powder;

[0031] (2) Preparation of hydrophobic nanocellulose particles: weigh 1g of nano...

Embodiment 3

[0034](1) Preparation of nanocellulose: Weigh 30g of dry bleached sulfate hardwood pulp, soak it in 10% NaOH solution for 12 hours, carry out dispersing (20000r), PFI beating (4000r), washing with distilled water and centrifuging three times (8000r) / min, 20min), freeze-dried for 48h. 5 g of the freeze-dried pulp sample was weighed, and 95 ml of distilled water was added to obtain a cellulose suspension with a concentration of 5%. 0.5 g of NaBr, 0.06 g of TEMPO, and 60 mmol of NaClO were added in sequence, and 0.1 mol / L of HCl and 0.1 mol / L of NaOH were added dropwise to control the pH of the reaction system to remain constant at 10. The slurry sample was then placed into a tank-type ultrasonic wave for ultrasonic vibration treatment for 3 hours, ethanol was added to terminate the reaction, centrifuged and washed three times (8000 r / min, 15 min), and freeze-dried to obtain nanocellulose powder;

[0035] (2) Preparation of hydrophobic nanocellulose particles: weigh 1g of nanoc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com