Low-temperature-resistant stretchable flexible hot melt adhesive and preparation method thereof

A low-temperature-resistant, hot-melt adhesive technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve complex problems, achieve enhanced flexibility and stretchability, wide application prospects, and improve uniformity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

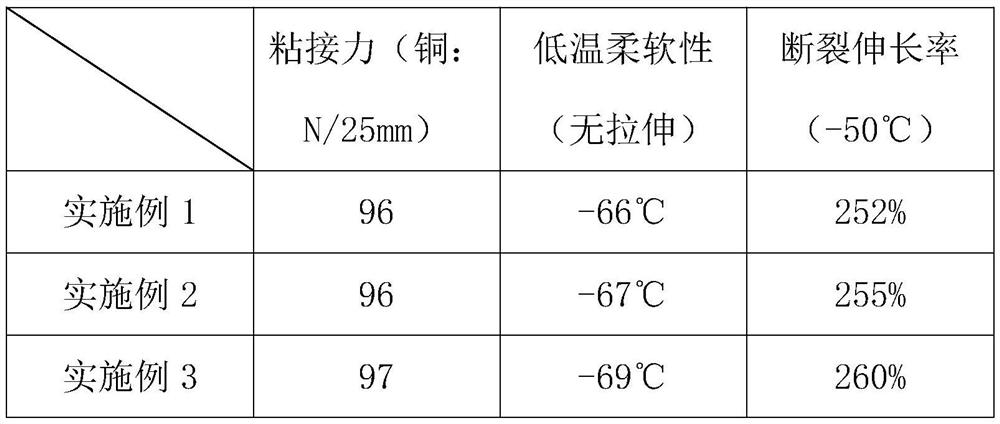

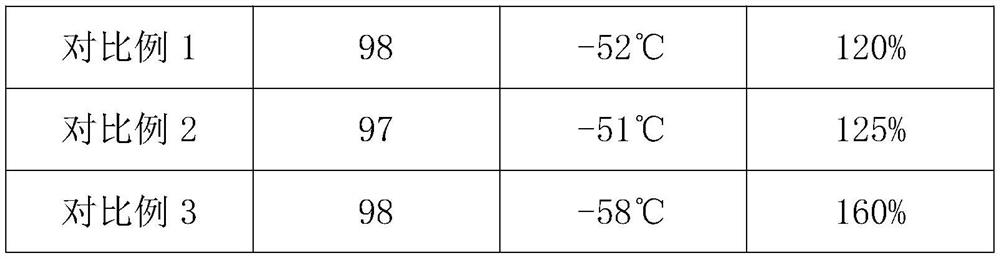

Examples

Embodiment 1

[0028] A flexible hot-melt adhesive resistant to low temperature and stretchable, which is composed of the following components in parts by weight: 100 parts of butyl rubber, 36 parts of silicone modified epoxy resin, 18 parts of polymethyl methacrylate, syndiotactic poly 6 parts of styrene-polyethylene block copolymer, 10 parts of paraffin wax, 2 parts of organic ultraviolet light absorber and 20 parts of talcum powder.

[0029] In this embodiment, the silicone-modified epoxy resin is prepared by condensation reaction of bisphenol-propane epoxy resin and dimethylpolysiloxane.

[0030] The preparation method of above-mentioned flexible hot-melt adhesive comprises the following steps:

[0031] S1: Weigh each raw material according to the weight of the configuration, first heat the base resin and silicone-modified epoxy resin to 110°C-120°C, melt and stir for 60-100min, then add 70% of the filler, continue to stir and mix, Obtain primary mixture;

[0032] S2: Add polymethyl me...

Embodiment 2

[0035] A flexible hot-melt adhesive resistant to low temperature and stretchable, which is composed of the following components in parts by weight: 100 parts of butyl rubber, 48 parts of silicone modified epoxy resin, 24 parts of polymethyl methacrylate, syndiotactic poly 8 parts of styrene-polyethylene block copolymer, 20 parts of paraffin wax, 4 parts of organic ultraviolet light absorber and 30 parts of talcum powder;

[0036] In this embodiment, the silicone-modified epoxy resin is prepared by condensation reaction of bisphenol-propane epoxy resin and dimethyl polysiloxane.

[0037] The preparation method of above-mentioned flexible hot-melt adhesive comprises the following steps:

[0038] S1: Weigh each raw material according to the weight of the configuration, first heat the base resin and silicone-modified epoxy resin to 110°C-120°C, melt and stir for 60-100min, then add 70% of the filler, continue to stir and mix, Obtain primary mixture;

[0039] S2: Add polymethyl m...

Embodiment 3

[0042] A low temperature resistant and stretchable flexible hot melt adhesive, which consists of the following components in parts by weight: 100 parts of butyl rubber, 42 parts of silicone modified epoxy resin, 21 parts of polymethyl methacrylate, syndiotactic poly 7 parts of styrene-polyethylene block copolymer, 15 parts of paraffin wax, 3 parts of organic ultraviolet light absorber and 25 parts of talcum powder;

[0043] In this embodiment, the silicone-modified epoxy resin is prepared by condensation reaction of bisphenol-propane epoxy resin and dimethyl polysiloxane.

[0044] The preparation method of above-mentioned flexible hot-melt adhesive comprises the following steps:

[0045] S1: Weigh each raw material according to the weight of the configuration, first heat the base resin and silicone-modified epoxy resin to 110°C-120°C, melt and stir for 60-100min, then add 70% of the filler, continue to stir and mix, Obtain primary mixture;

[0046]S2: Add polymethyl methacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile properties | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com