Method for optimizing corrosion inhibition efficiency of corrosion inhibitors in carrier

A corrosion inhibitor and carrier technology, which is applied in the field of optimizing the corrosion inhibition efficiency of corrosion inhibitors in carriers, can solve unfavorable loading corrosion inhibitor carrier technology development and application of self-healing coating technology, and the carrier cannot exert the effect of corrosion inhibitors to antagonize Effect and other issues, to achieve the effect of optimizing corrosion inhibition efficiency, improving corrosion inhibition performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Two different corrosion inhibitors: benzotriazole (BTA) and cerium nitrate (Ce(NO 3 ) 3 ) according to the total concentration of 0.2g / L, respectively dissolved in 3.5wt% NaCl solution in the mass ratio of 0:4, 1:3, 2:2, 3:1, 4:0.

[0041] (2) Soak the Q235 carbon steel sample in the above NaCl solution, take it out after an interval of 1h, and observe the surface morphology of the Q235 carbon steel sample.

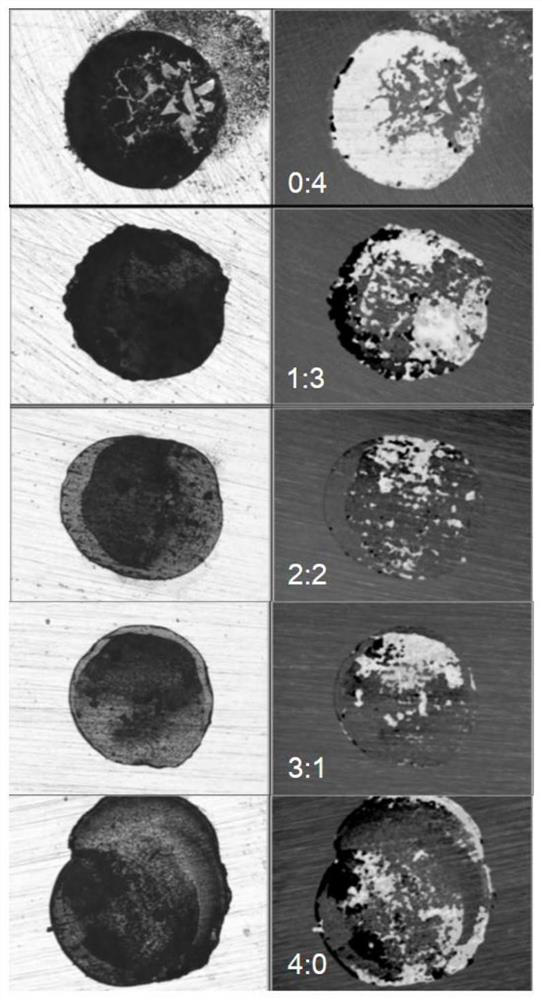

[0042] figure 1 For example 1 with BTA and Ce (NO 3 ) 3 In order to compound the corrosion inhibitor system, different proportions of corrosion inhibitors were dissolved in 3.5wt.% NaCl solution, and the metal sample was selected as Q235 carbon steel sample, and the corrosion product morphology on the surface of Q235 carbon steel sample . This example shows that when benzotriazole (BTA) and cerium nitrate (Ce(NO 3 ) 3 ) when the ratio of the corrosion inhibitor is 2:2, the corrosion products produced on the surface of the Q235 carbon steel sample are the...

Embodiment 2

[0044] (1) Put two different corrosion inhibitors: benzotriazole (BTA) and 2-mercaptobenzothiazole (2-MBT) according to the total concentration of 0.6g / L, 6:0, 5:1, 4: The mass ratio of 2 is dissolved in 3.5wt% NaCl solution.

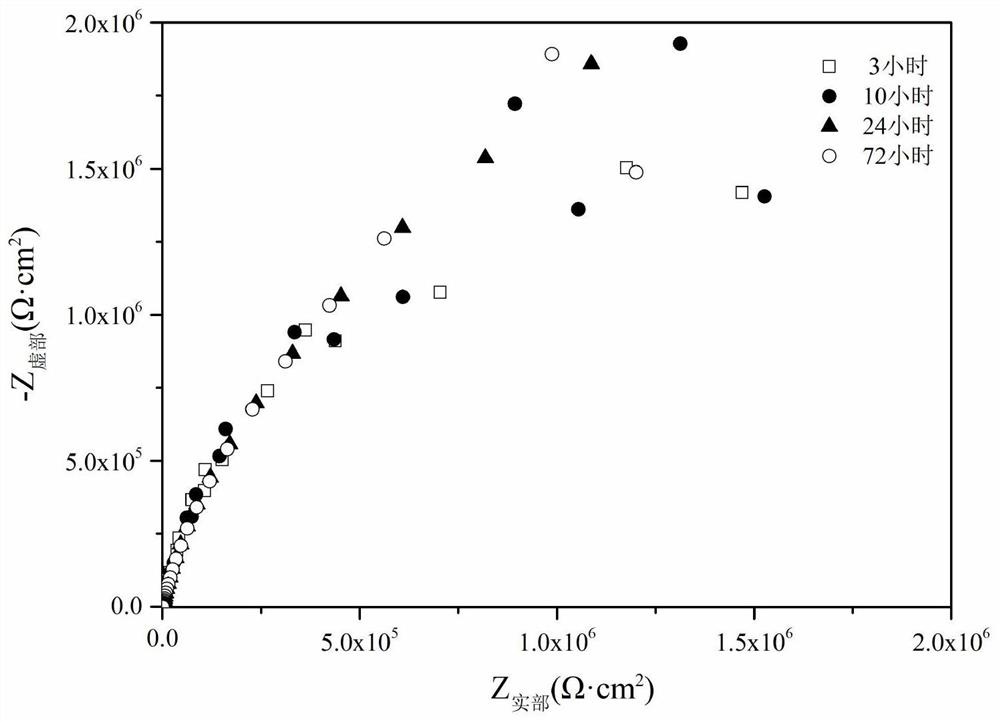

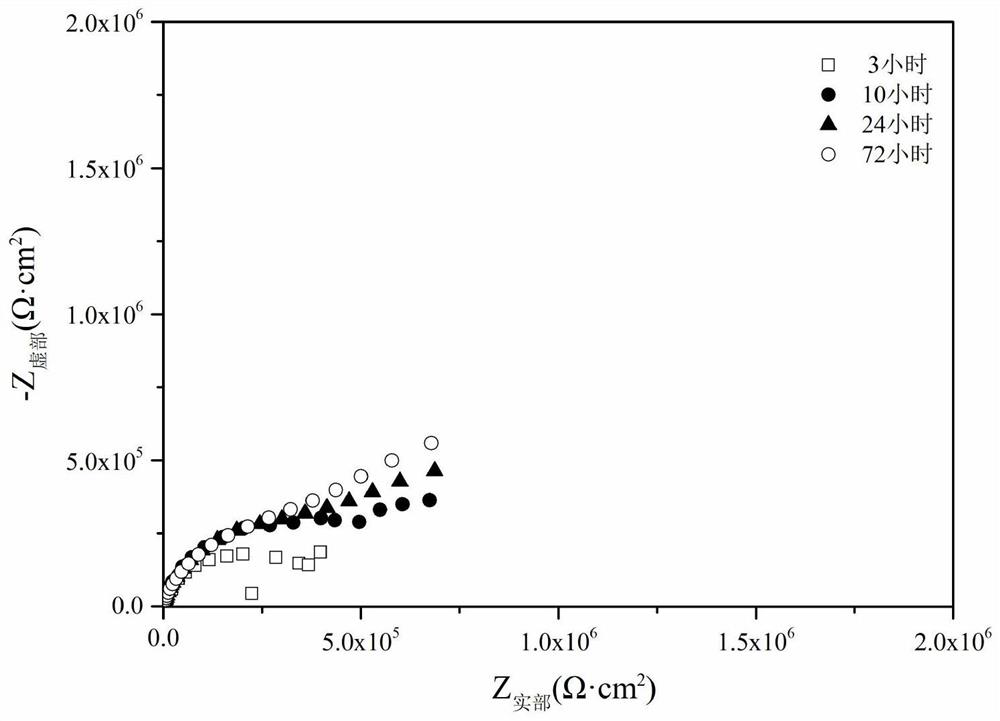

[0045] (2) Soak the AA2024 aluminum alloy in the 3.5wt% NaCl solution containing the corrosion inhibitor, use the electrochemical impedance spectroscopy of the three-electrode measurement system, and compare the impedance modulus to determine the quality of the synergistic effect of the corrosion inhibitor. The ratio is 5:1.

[0046] (3) BTA and 2-MBT with a mass ratio of 5:1 were simultaneously loaded in mesoporous silica nanospheres by a one-step in-situ loading method, and the actual loading in the nanocarrier was measured by a UV-visible spectrophotometer. The ratio of the corrosion inhibitor concentration, if the ratio is not equal to 5:1, then adjust the mass ratio of BTA and 2-MBT added to the mesoporous silica, and prepare the mesoporous silica...

Embodiment 3

[0051] (1) Dissolve benzotriazole (BTA) and 2-mercaptobenzothiazole (2-MBT) in 3.5 wt. % NaCl solution.

[0052] (2) Soak the AA2024 aluminum alloy in the above-mentioned corrosion inhibitor solution, use the three-electrode system to measure the electrochemical impedance spectrum of the system, and compare the impedance modulus, it is determined that the optimal compounding ratio of the corrosion inhibitor synergistic effect is 5: 1.

[0053] (3) To prepare calcium carbonate micro-nanospheres, load BTA and 2-MBT respectively in calcium carbonate micro-nanospheres by low-pressure loading method: mix sodium dodecylbenzenesulfonate and sodium carbonate at a ratio of 1:1 to obtain Emulsion A, calcium chloride and sodium dodecylbenzenesulfonate were uniformly mixed to obtain emulsion B, and emulsion A and emulsion B were mixed and reacted for 20 minutes to obtain calcium carbonate micro-nanospheres. The prepared calcium carbonate micro-nanospheres and the corrosion inhibitor sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com