SOI LDMOS device capable of improving self-heating effect

A self-heating effect and device technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of hindering heat release, total dose effect, etc., to reduce the amount of collection, improve the overall performance, and ensure the performance of anti-single particle burnout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

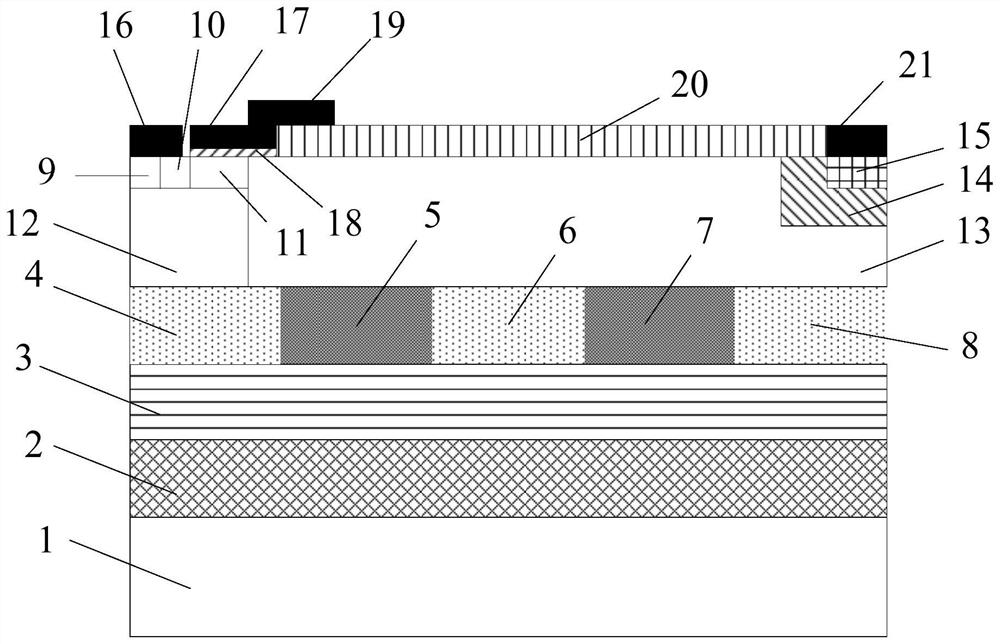

[0017] This application discloses a SOI LDMOS device that improves the self-heating effect, please refer to figure 1 , the SOI LDMOS device includes a substrate silicon layer 1, a P-type heavily doped silicon layer 2, an N-type lightly doped semiconductor layer 3 and an active region structure, and the P-type heavily doped silicon layer 2 is stacked on the substrate silicon layer 1, the N-type lightly doped semiconductor layer 3 is stacked on the P-type heavily doped silicon layer 2, and the active region structure is set on the N-type lightly doped semiconductor layer 3, and the N-type lightly doped semiconductor layer 3 adopts a wide Made of forbidden material. Wherein, the heavy doping and light doping of the P-type heavily doped silicon layer 2 and the N-type lightly doped semiconductor layer 3 are relative, and there is no specific dop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com