Electrolyte containing phenyl sulfonate compound and lithium ion battery

A technology containing phenyl sulfonate and lithium-ion batteries, which can be used in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., and can solve the problems of effectively improving the high-temperature cycle performance of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

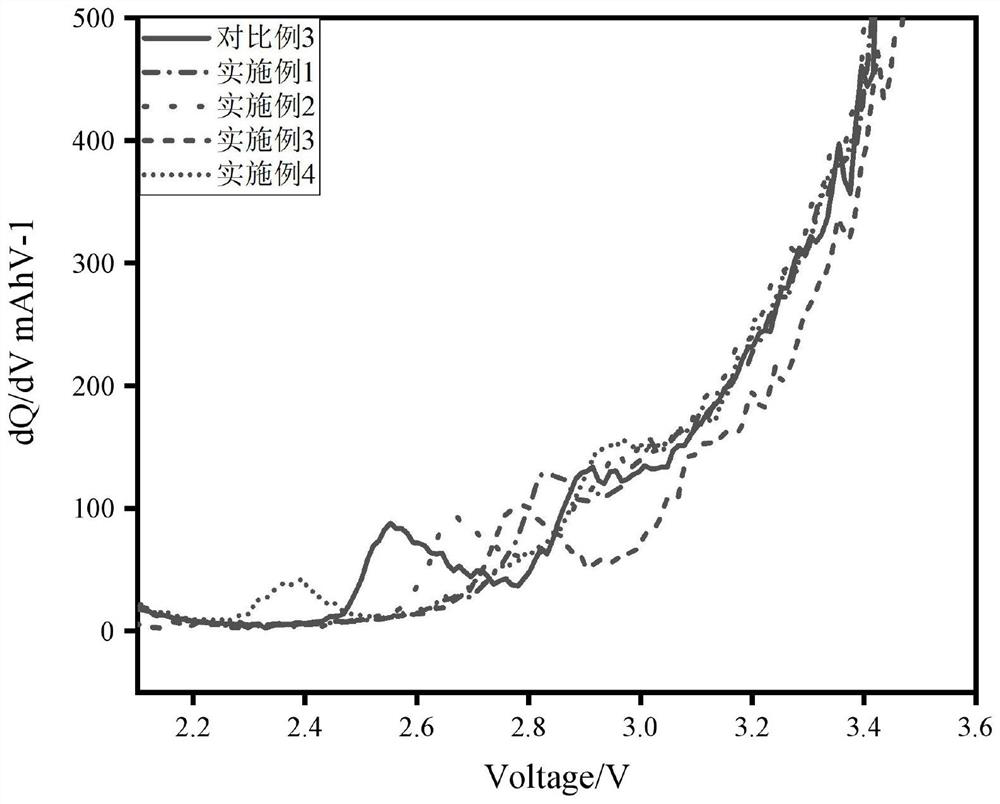

Embodiment 1

[0032] (1) Electrolyte composition:

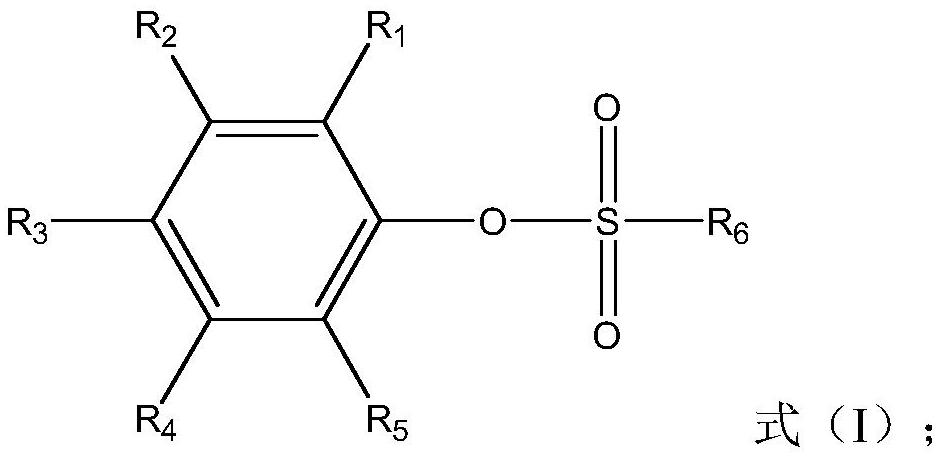

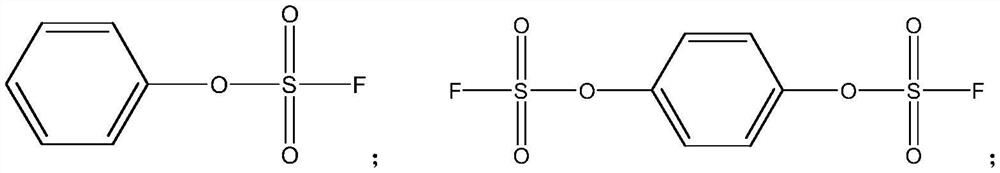

[0033] The structural formula of the electrolyte first additive in the present embodiment is as formula (I 1 ) shown.

[0034]

[0035] Formula (I 1) compound is prepared by adding phenol, toluene and triethylamine into the reactor at room temperature under a nitrogen atmosphere, and then adding sulfonyl fluoride into the reactor at 0°C to 10°C. The reaction temperature is adjusted to 40° C. to 50° C.; the reaction time is 1 h to 4 h. Wherein the ratio of sulfonyl fluoride to phenol is 1:1. The ratio of the amount of substance of sulfonyl fluoride to the amount of substance of triethylamine was 1:1.

[0036] In the present embodiment, formula (I 1 ) represents 1% of the weight of the electrolytic solution; the second additive is citraconic anhydride, which accounts for 0.5% of the weight of the electrolytic solution; the lithium salt is lithium hexafluorophosphate, and the lithium salt accounts for 13% of the weight of the electrol...

Embodiment 2

[0040] (1) Electrolyte composition:

[0041] The structural formula of the electrolyte first additive in the present embodiment is as formula (I 2 ) shown.

[0042]

[0043] Formula (I 2 ) compound is prepared by adding hydroquinone, toluene and triethylamine into the reaction kettle at room temperature under nitrogen protection atmosphere, and then adding sulfonyl fluoride into the reaction kettle at 0°C to 10°C. The reaction temperature is adjusted to 40° C. to 50° C.; the reaction time is 1 h to 4 h. Wherein the ratio of sulfonyl fluoride to hydroquinone is 2:1. The ratio of the amount of substance of sulfonyl fluoride to the amount of substance of triethylamine was 1:1.

[0044] In the present embodiment, formula (I 2 ) represents 1% of the weight of the electrolytic solution; the second additive is citraconic anhydride, which accounts for 0.5% of the weight of the electrolytic solution; the lithium salt is lithium hexafluorophosphate, and the lithium salt accounts...

Embodiment 3

[0048] (1) Electrolyte composition:

[0049] The structural formula of the electrolyte first additive in the present embodiment is as formula (I 3 ) shown.

[0050]

[0051] In the present embodiment, formula (I 3 ) represents 1% of the weight of the electrolytic solution; the second additive is citraconic anhydride, which accounts for 0.5% of the weight of the electrolytic solution; the lithium salt is lithium hexafluorophosphate, and the lithium salt accounts for 13% of the weight of the electrolytic solution; the solvent It is a solvent mixed with ethylene carbonate and ethyl methyl carbonate at a weight ratio of 1:2; the electrolyte solution of this example was prepared according to the conventional electrolyte preparation method.

[0052] (2) Assemble the lithium-ion battery:

[0053] The cathode material is LiNi 0.8 co 0.1 mn 0.1 o 2 ; The negative electrode material is artificial graphite; the diaphragm is polyethylene film; the electrolyte is the electrolyte ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com