Optical fiber isolator

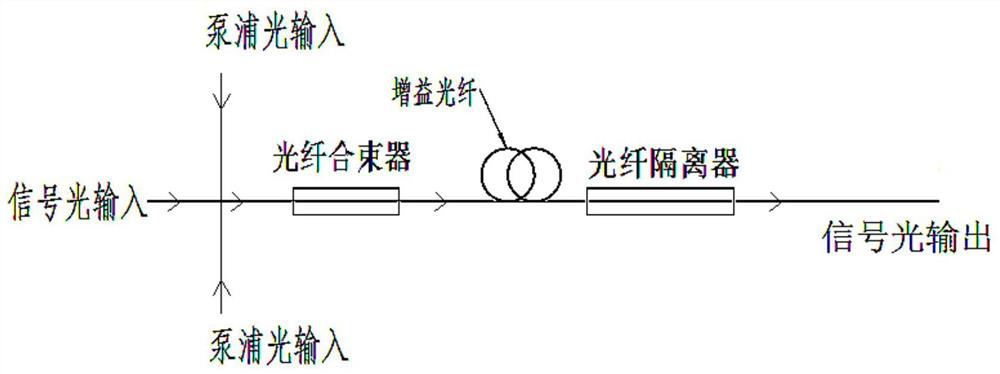

A fiber optic isolator and isolation module technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of complex system structure, low integration, and multiple melting points, so as to reduce production costs, reduce fusion points, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

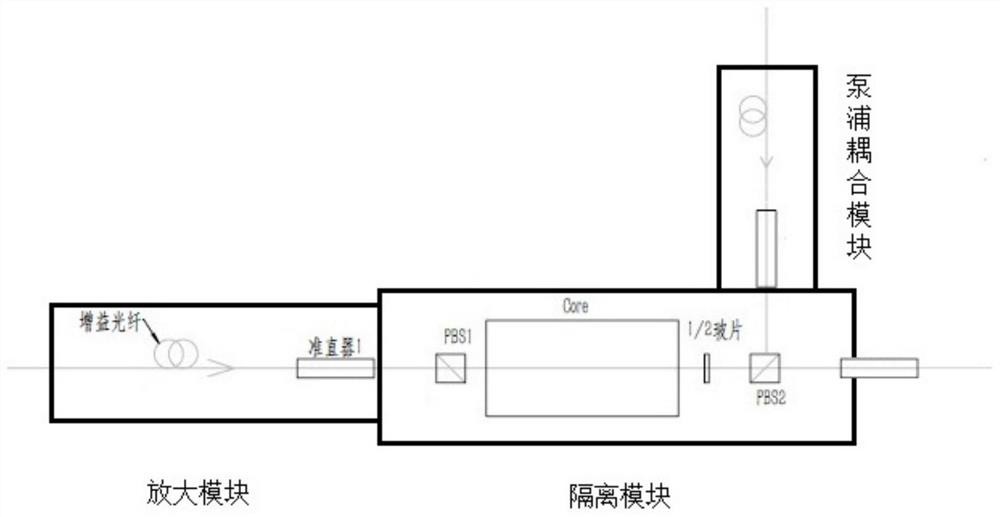

[0040] Such as figure 2 As shown, the fiber isolator in this embodiment includes an amplification module, a pump coupling module and an isolation module; the amplification module includes a gain fiber and a collimator 1 connected in sequence; the pump coupling module includes a passive fiber 1 connected in sequence and the second collimator; the isolation module includes the first polarization beamsplitter prism (PBS1), Faraday rotator (Core), 1 / 2 glass slide, the second polarization beamsplitter prism (PBS2), the third collimator and Passive optical fiber 2; wherein, the pump coupling module is arranged at the rear end of the isolation module, which is suitable for polarization-maintaining fiber core pump amplification mode, and plays the role of pump reverse coupling, amplification and isolation.

Embodiment 2

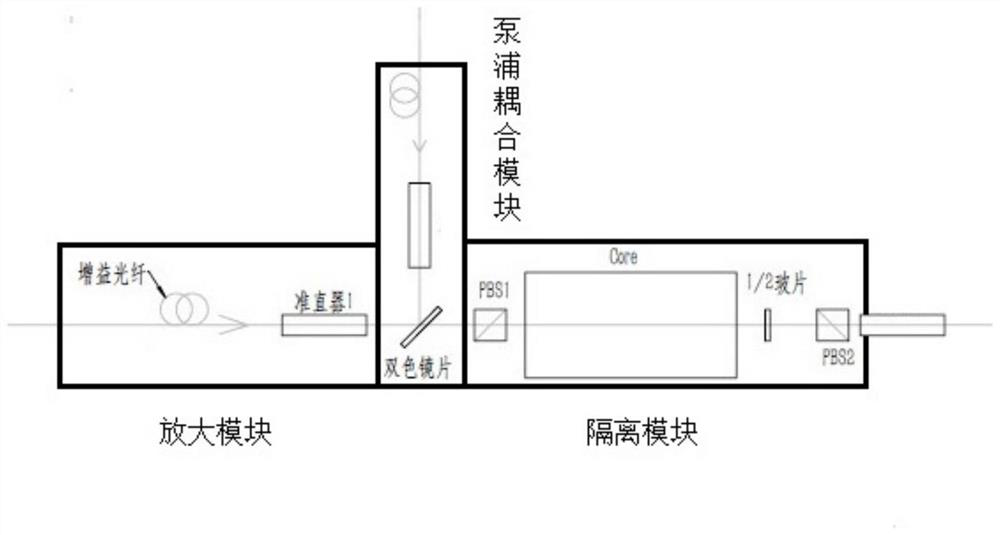

[0042] Such as image 3 As shown, the difference from Embodiment 1 is that the pump coupling module in the fiber isolator in this embodiment is arranged at the front end of the isolation module, which is suitable for core pumping and cladding pumping, and the pumping light does not pass through the Faraday optical rotator.

Embodiment 3

[0044] Such as Figure 4 As shown, on the basis of Embodiment 1, further, the output mode of the optical fiber isolator in this embodiment is optical fiber output, that is, an online optical fiber isolator, which is generally used in the middle of a fiber laser system to serve as a coupling pump , amplification, and isolation; its structure includes: gain fiber, collimator 1 (the first collimator), PBS1 (the first polarization beam splitter), Core (Faraday rotator), 1 / 2 slide, PBS2 ( second polarization beam splitter), collimator 2 (second collimator); wherein, gain fiber, collimator 1, PBS1, Faraday rotator, 1 / 2 slide, PBS2, collimator 3 and passive The optical fiber 2 is connected sequentially; the passive optical fiber 1 is directly connected to the input end of the collimator 2, and the output end of the collimator 2 is connected to the PBS2. After being collimated by the collimator 3, the amplified signal light passes through the wireless Source fiber 2 output. The firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com