High-flame-retardant antimony trioxide master batch

A technology of antimony trioxide and high flame retardancy, which is applied in the field of high flame retardancy antimony trioxide masterbatch, which can solve the problems of reduced flame retardancy, carcinogenicity, dermatitis, etc., achieves favorable flame retardancy and improves compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example A

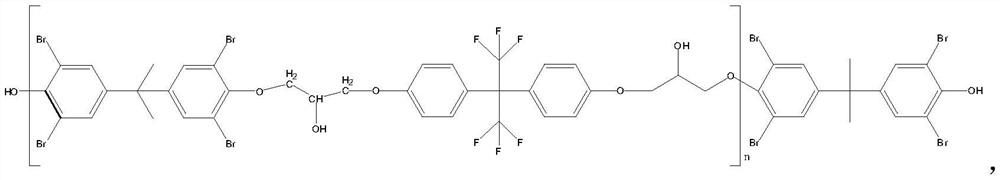

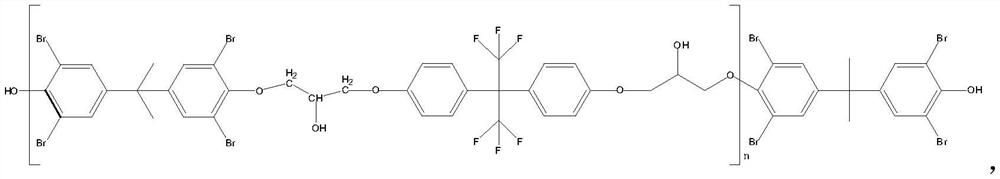

[0030] Add 1kg of hexafluorobisphenol A into a 5L reactor, add 3.3kg of epichlorohydrin, and start stirring.

[0031] Raise the temperature of the reaction kettle to 45°C, wait until the hexafluorobisphenol A is completely dissolved in epichlorohydrin, add 165g of sodium hydroxide, raise the temperature to 60°C, and continue the reaction for 4 hours, then start vacuuming, and control the vacuum degree to 20kPa, epichlorohydrin begins to reflux; In the reaction solution, add 693g of 50% sodium hydroxide aqueous solution dropwise at a constant speed, after the dropwise addition is completed, the temperature is raised to 75°C, and water removal begins. After the water removal is completed, the temperature is raised to 130°C, start to remove excess epichlorohydrin;

[0032] After epichlorohydrin was completely removed, add 2kg of methyl isobutyl ketone (MIBK) to the system, and 50% aqueous sodium hydroxide solution of 693g, after fully stirring, layering removes the water layer, ...

Synthetic example B1

[0035] Add 225g of the hexafluorobisphenol A epoxy resin obtained in Synthesis Example A and 326g of tetrabromobisphenol A into the system, raise the temperature to 85°C under stirring, add 6g of catalyst triphenylphosphine, and the system will naturally release Heat, control the temperature not to exceed 120°C.

[0036] Continue the temperature control reaction until the heat needs to be supplemented to keep warm. Start timing at 120°C, and then measure the epoxy value every two hours until the epoxy value <0.01 to stop the reaction, and the flame retardant synergist is obtained.

Synthetic example B2

[0038] Add 202g of hexafluorobisphenol A epoxy resin obtained in Synthesis Example A and 272g of tetrabromobisphenol A into the system, raise the temperature to 85°C under stirring, add 5.5g of catalyst triphenylphosphine, and the system will naturally Exothermic, control the temperature not to exceed 120°C.

[0039] Continue the temperature control reaction until the heat needs to be supplemented to keep warm. Start timing at 120°C, and then measure the epoxy value every two hours until the epoxy value <0.01 to stop the reaction, and the flame retardant synergist is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com