Glass pretreatment liquid, and preparation method and application thereof

A technology of pretreatment liquid and preparation method, which is applied in chemical instruments and methods, detergent compounding agent, preparation of detergent mixture compositions, etc., can solve problems such as poor use effect, and reduce operation complexity and raw material price Inexpensive, good cleaning results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

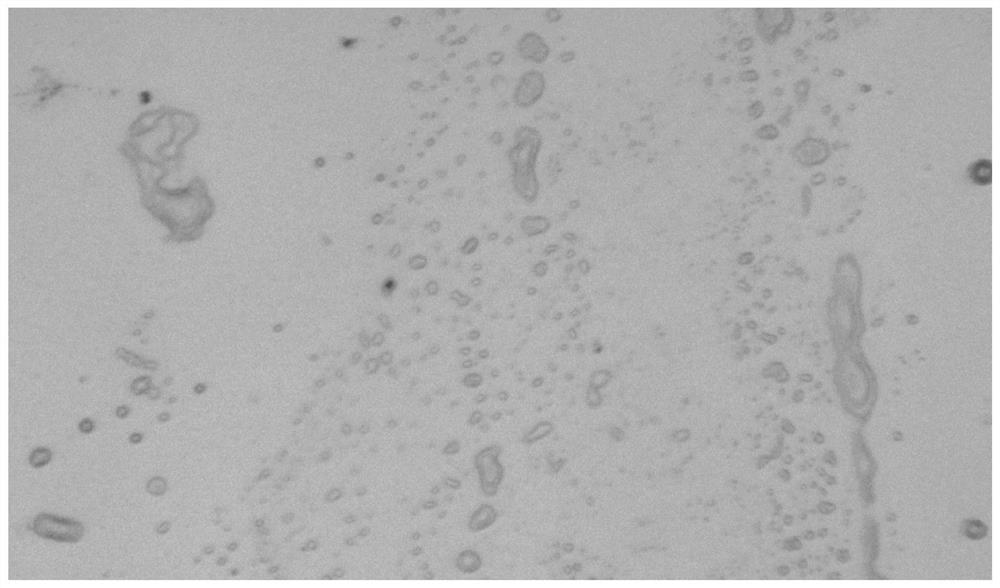

Image

Examples

Embodiment 1

[0040] The present embodiment provides a kind of preparation method of glass pretreatment liquid, and its step comprises:

[0041] S100, taking sulfuric acid according to a certain volume ratio and adding an appropriate amount of deionized water to mix evenly to obtain a mixed solution A; wherein the mass fraction of sulfuric acid is 98%;

[0042] S200. Weigh ammonium bifluoride and sodium fluoride according to a certain weight ratio and add them to the mixed solution A, and mix evenly to obtain the mixed solution B;

[0043] S300. Measure nitric acid according to a certain volume ratio and add it to the mixed solution B and mix evenly to obtain the mixed solution C;

[0044] S400. Measure benzalkonium bromide according to a certain volume ratio and add it to the mixed solution C and mix evenly to obtain the glass pretreatment solution.

[0045] The above steps are carried out at a temperature above 45°C, and the pretreatment liquid prepared by the above steps includes 5% nitri...

Embodiment 2

[0048] The preparation steps of this embodiment are basically the same as those of Example 1, except that the glass pretreatment solution prepared in this embodiment includes the following components: 8% nitric acid, 15% sulfuric acid, 9% ammonium bifluoride, 3.5% sodium fluoride, 2% benzalkonium bromide and appropriate amount of deionized water; wherein, the temperature of the solution is controlled above 45° C. to obtain a finished product. By using nitric acid, sulfuric acid, ammonium bifluoride, sodium fluoride, benzalkonium bromide and deionized water as raw materials to prepare glass pretreatment liquid, it is not only cheap, but also has a good cleaning effect, and does not need to be cleaned many times, reducing work strength. At the same time, the glass pretreatment solution prepared in this embodiment is used to treat the glass to be etched, and the treatment effect is basically the same as that in embodiment 1.

Embodiment 3

[0050] The preparation steps of this embodiment are basically the same as those of Example 1, except that the glass pretreatment solution prepared in this embodiment includes the following components: 10% nitric acid, 15% sulfuric acid, 8% ammonium bifluoride, 3.5% sodium fluoride, 2% benzalkonium bromide, and an appropriate amount of deionized water; wherein, the temperature of the solution is controlled above 45°C to obtain a finished product; by using nitric acid, sulfuric acid, ammonium bifluoride, sodium fluoride, Benzalkonium bromide and deionized water are used as raw materials to prepare the glass pretreatment solution, which is not only cheap, but also has a good cleaning effect, without the need for multiple cleanings, which reduces the work intensity. At the same time, the glass pretreatment solution prepared in this embodiment is used to treat the glass to be etched, and the treatment effect is basically the same as that in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com