Multifunctional sensing integrated flexible fabric-based sensor and application thereof

A flexible fabric and sensor technology, applied in the direction of converting sensor output, fabric, and using electromagnetic/magnetic devices to transmit sensing components, can solve the problems of inability to meet the working environment of the sensor, interfere with the accuracy of the pressure signal, and single sensor function, and achieve Excellent flexibility and anti-interference performance, optimized overall performance, high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

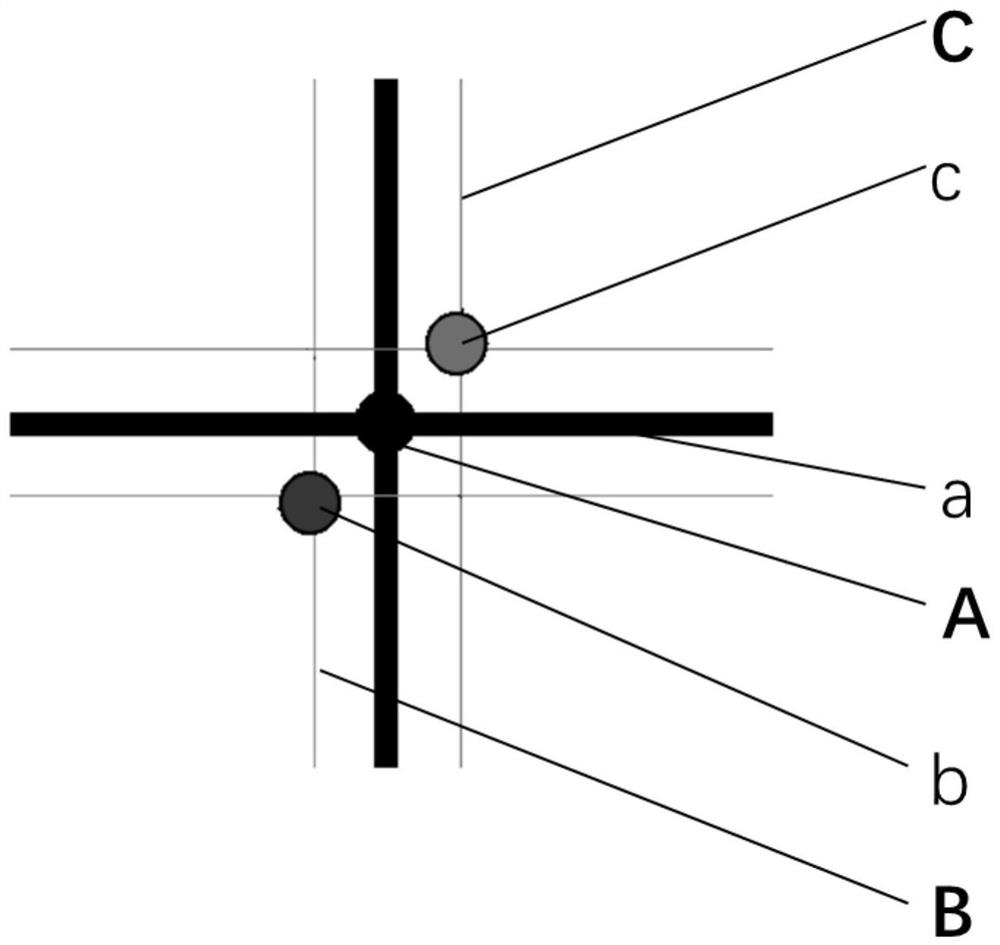

[0065] see figure 1As shown, the embodiment of the present invention provides a flexible fabric-based sensor with multifunctional sensor integration. The flexible fabric-based sensor integrated with multifunctional sensing is obtained by interweaving three sets of mutually independent warp and weft yarn systems composed of three different sensing function yarns; the three sets of mutually independent The warp and weft systems are warp and weft system A composed of pressure sensing functional yarns, warp and weft system B composed of temperature sensing functional yarns, and warp and weft system C composed of humidity sensing functional yarns ; The ends of the pressure sensing functional yarn, the temperature sensing functional yarn, and the humidity sensing functional yarn are all provided with collecting electrodes for collecting the pressure sensing functional yarn, the temperature Sensing functional yarns, signals at both ends of the humidity sensing functional yarns and s...

Embodiment 2

[0088] The difference from Embodiment 1 is that in Embodiment 2, the types of dielectric materials used are different.

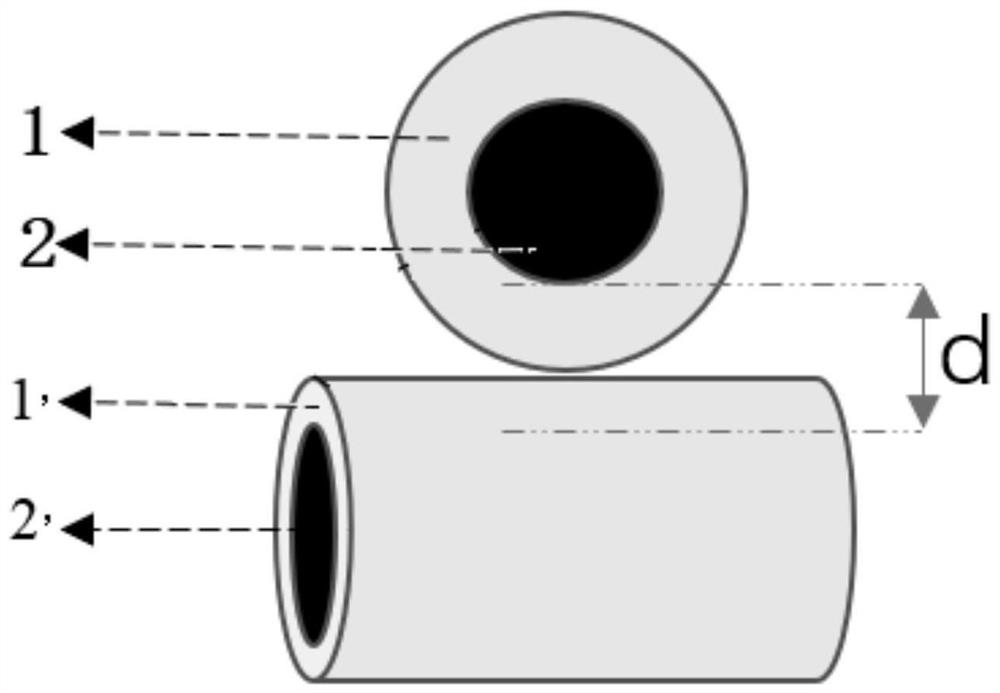

[0089] According to the capacitance calculation formula C=εS / d, ε is the dielectric coefficient, S is the electrode area, and d is the electrode distance. In the case of a certain yarn area, in order to increase the capacitance of the sensing unit, it is necessary to increase the dielectric coefficient ε, that is, by changing the ε of the dielectric layer material. The effect of optimizing the overall performance can be achieved by increasing ε.

[0090] In this solution, the elastic medium material is polyurethane; in the temperature-sensitive polymer material added with heat-conducting filler, the heat-conducting filler is graphene, and the temperature-sensitive polymer material is temperature-sensitive rubber; the humidity-sensitive polymer The material is chitosan.

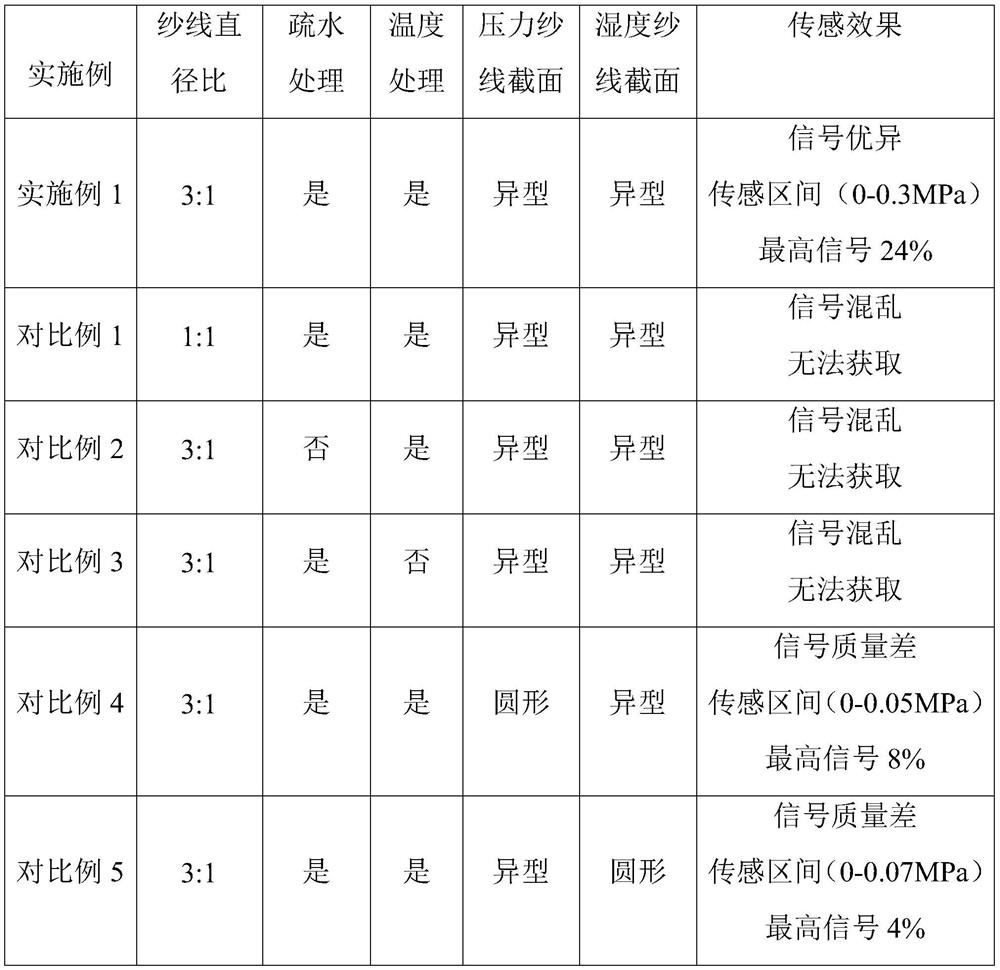

[0091] Such as Figure 4 As shown, the pressure, temperature, and humidity sensing ef...

Embodiment 3

[0111] The difference from Example 1 is that in Example 3, the sensory functional yarn is a composite yarn composed of several sensory functional fibers; the sensory functional fiber is a two-component sheath-core structure In the composite fiber, the skin layer is the dielectric material with sensing function, and the core layer is the electrode material.

[0112] After anti-interference treatment and fibers with different sensing functions are compounded into three different functional yarns, the flexible fabrics are woven through three independent warp and weft yarn systems respectively, and a flexible sensor integrated with multifunctional sensors is prepared. Fabric based sensors. The three interwoven but independent sub-sensor systems (pressure sensor, temperature sensor, humidity sensor) in the flexible fabric-based sensor perform independent functional signal sensing with high stability and do not interfere with each other, and the final signal system Integration for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com