Binder composition for electricity storage devices, slurry for electricity storage device electrodes, electricity storage device electrode, and electricity storage device

A technology for electrical storage devices and compositions, which is applied to non-aqueous electrolyte battery electrodes, battery electrodes, electrode current collector coatings, etc., can solve problems such as capacity reduction, active material peeling, and inability to maintain tightness, and achieve improved performance. Flexibility and adhesion, and the effect of improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0188] 2.2.4. Preparation method of slurry for storage device electrodes

[0189] The slurry for electrical storage device electrodes which concerns on this embodiment can be manufactured by any method as long as it contains the binder composition for electrical storage devices mentioned above, and an active material. From the viewpoint of more efficiently and inexpensively producing a slurry with better dispersibility and stability, it is preferable to add an active material and any optional additive components used as necessary to the binder composition for electrical storage devices. These are mixed and manufactured. As a specific production method, the method described in Japanese Patent No. 5999399 etc. is mentioned, for example.

[0190] 3. Electrode of electrical storage equipment

[0191] The electrical storage device electrode according to the present embodiment includes a current collector and an active material layer formed by applying and drying the above-mention...

Embodiment 2~22

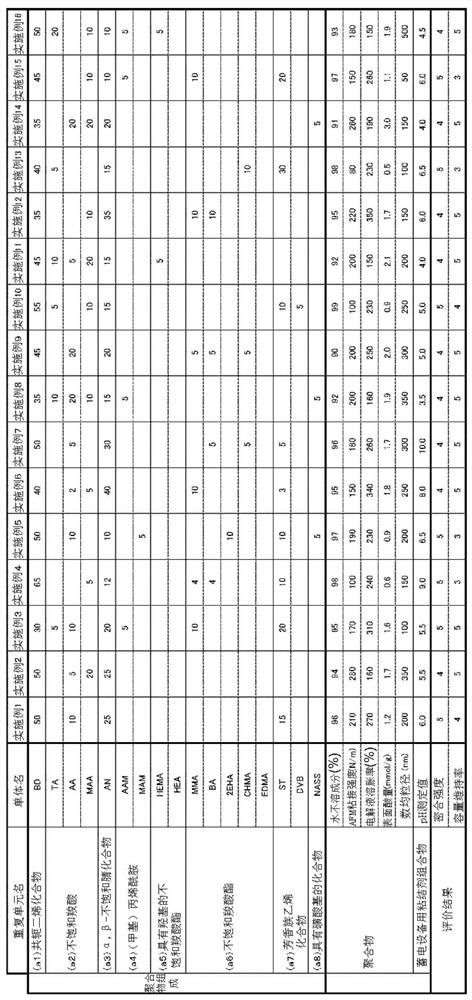

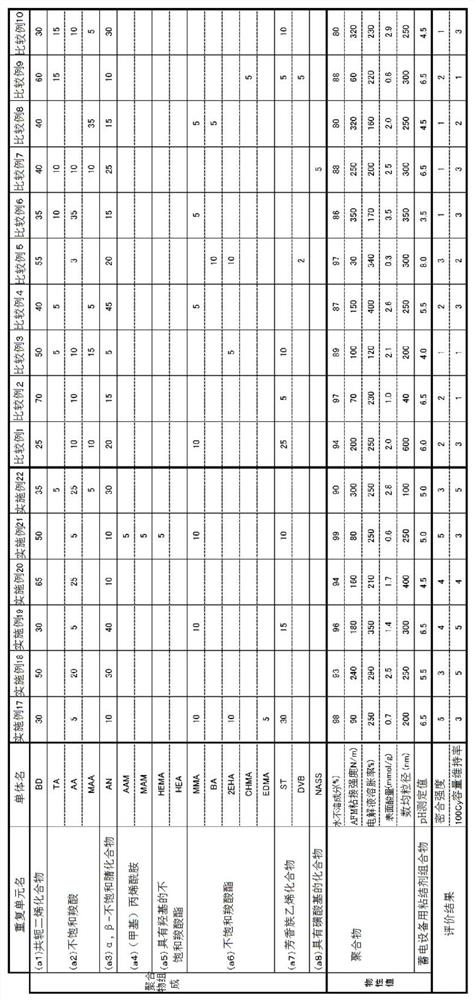

[0251] 5.2. Examples 2-22, Comparative Examples 1-10

[0252] In the above "5.1.1. Preparation and evaluation of binder composition for electrical storage equipment (1) Preparation of binder composition for electrical storage equipment", the types and amounts of each monomer are listed in Table 1 or the following table respectively As described in 2, except that, the binder composition for electrical storage devices containing 20 mass % of polymer particles was obtained similarly.

[0253] And, using the binder composition for an electrical storage device prepared above, except that, the slurry for an electrical storage device electrode was prepared in the same manner as in the above-mentioned Example 1, and an electrical storage device electrode and an electrical storage device were respectively prepared. Evaluation was performed in the same manner as in Example 1 above.

Embodiment 23

[0255] In Example 20, as the thickener, 0.9 parts by mass of CMC (trade name "CMC2200", manufactured by Daicel Co., Ltd.) and CNF (trade name "CELISH KY-100G" manufactured by Daicel Co., Ltd., fiber diameter 0.07 μm) 0.1 parts by mass, the slurry for electrical storage device electrodes was prepared in the same manner as in Example 20, and an electrical storage device electrode and an electrical storage device were produced, respectively, and evaluated in the same manner as in Example 1 above. The results are shown in Table 3 below.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap