Chinese chestnut pudding and preparation method thereof

A technique for chestnut and pudding, applied in the field of slow-digestion and anti-digestion chestnut pudding preparation, can solve problems such as long shelf life and lack of systematic research, and achieve bright color, good gel formability, and simple preparation process and processing equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

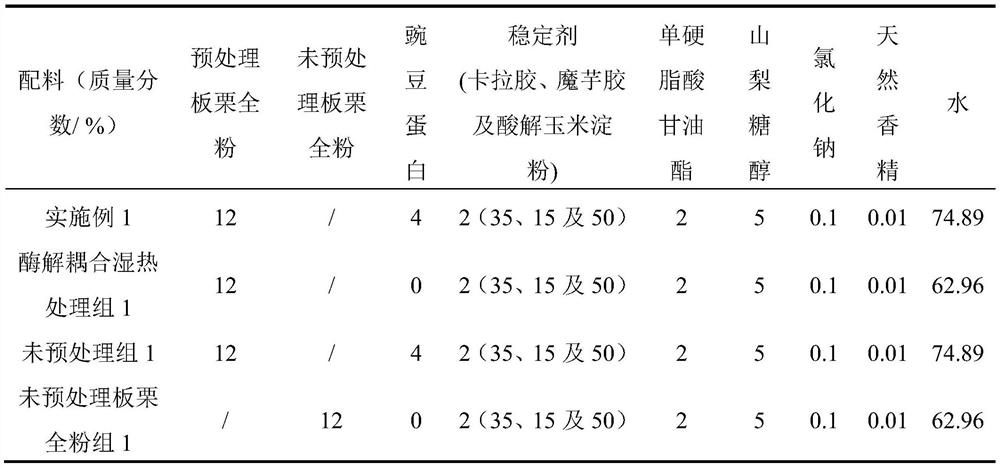

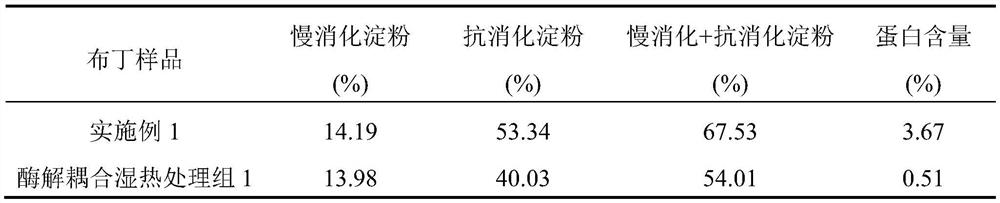

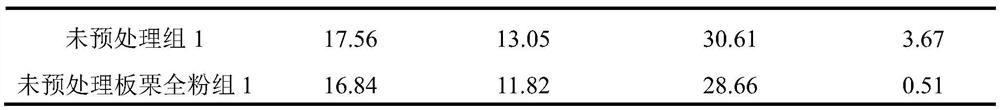

Embodiment 1

[0028]Accurately weigh 1 kg of whole chestnut powder, add an appropriate amount of water to adjust to 8% (w / w) slurry, add pullulanase in an amount of 25U / g (dry basis of whole chestnut powder), and enzyme at 58°C hydrolysis treatment for 60 minutes; then adjust the moisture content of enzymatic hydrolysis chestnut whole powder to 25%, and wet heat treatment at 110° C. for 120 minutes to obtain enzymatic hydrolysis coupling wet heat treatment chestnut whole powder.

[0029] The pea protein and the whole chestnut powder treated with enzymatic hydrolysis coupled with heat and humidity were added to water at a mass ratio of 1:3 to form a slurry with a total solid content of 25%; then sheared at 90°C and 6000rpm for 25 minutes at a high-speed thermal shear rate. This slurry is pre-mixed with stabilizers (carrageenan, konjac gum and acid hydrolyzed cornstarch), glyceryl monostearate, sorbitol, sodium chloride and natural flavors prepared according to the ratio of each component in T...

Embodiment 2

[0043] Accurately weigh 1kg of whole chestnut powder, add an appropriate amount of water to adjust to 8% (w / w) slurry, add pullulanase in an amount of 100U / g (dry basis of whole chestnut powder), and enzyme at 58°C hydrolysis treatment for 30 minutes; then adjust the moisture content of enzymatic hydrolysis chestnut whole powder to 30%, and wet heat treatment at 90° C. for 180 minutes to obtain enzymatic hydrolysis coupling wet heat treatment chestnut whole powder. The pea protein and the whole chestnut powder treated with enzymatic hydrolysis coupled with heat and humidity were added to water at a mass ratio of 1:2 to form a slurry with a total solid content of 25%; then sheared at 95°C and 4500rpm for 10 minutes at a high-speed thermal shear rate. This slurry is pre-mixed with the stabilizer (carrageenan, konjac gum and acid hydrolyzed cornstarch), glyceryl monostearate, sorbitol, sodium chloride and natural essence etc. prepared according to the ratio of each component in Ta...

Embodiment 3

[0052] Accurately weigh 1 kg of whole chestnut powder, add an appropriate amount of water to adjust to an 8% (w / w) slurry, add pullulanase in an amount of 10 U / g (dry basis of whole chestnut powder), and enzyme at 58°C hydrolysis treatment for 120 minutes; then adjust the moisture content of enzymatic hydrolysis chestnut whole powder to 15%, and heat and heat treatment at 120°C for 60 minutes to obtain whole chestnut powder coupled with enzymatic hydrolysis and heat and humidity treatment. The pea protein and the whole chestnut powder treated with enzymatic hydrolysis coupled with heat and humidity were added to water at a mass ratio of 1:4 to form a slurry with a total solid content of 25%; then sheared at 85°C and 7500rpm for 15 minutes at a high-speed thermal shear rate. This slurry is pre-mixed with the stabilizer (carrageenan, konjac gum and acid hydrolyzed cornstarch), glyceryl monostearate, sorbitol, sodium chloride and natural essence etc. prepared according to the rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com