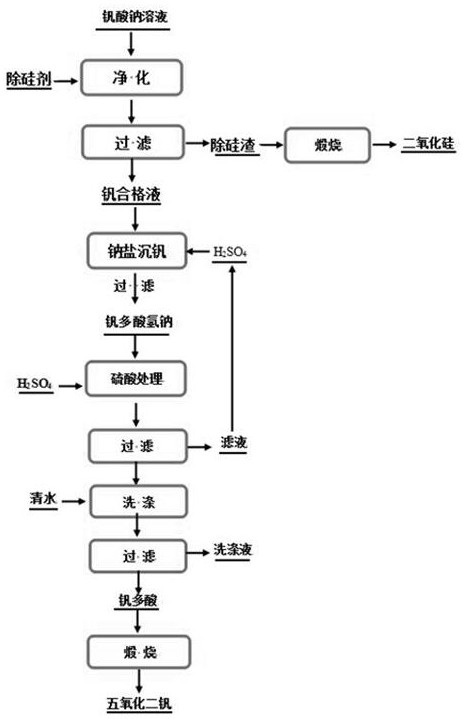

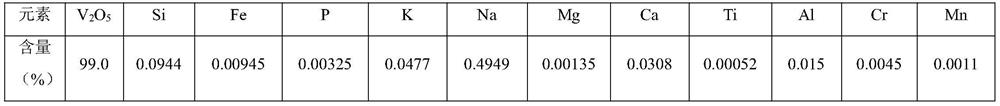

Method for preparing high-purity vanadium pentoxide through sodium salt vanadium precipitation of sodium vanadate solution

A technology of vanadium pentoxide and sodium vanadate, which is applied in the direction of vanadium oxide, etc., can solve the problems of low purity, large consumption of chemicals, increased process cost, etc., and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing high-purity vanadium pentoxide by precipitating vanadium from sodium vanadate solution, comprising the following steps:

[0031] 1) Take 50mL of sodium vanadate solution (the content of vanadium element is 41.79g / L, the content of silicon element is 1.2585g / L), after adjusting the pH of the sodium vanadate solution to 2.4 with sulfuric acid, add 0.1g of anionic polyacrylamide CPAM, stirred and reacted at a stirring speed of 200r / min at room temperature for 30min; stood still for 14h, suction filtered, and washed the filter residue with deionized water for 2 to 3 times, the measured desiliconization rate was 86.04%, the vanadium loss rate was 0.19%, and the filtrate Known as vanadium qualified liquid;

[0032] 2) At room temperature, add the qualified vanadium solution dropwise to 0.5 mol / L sulfuric acid solution while stirring until the pH of the mixed solution is 1.8, and stir the mixed solution at T=90°C at a stirring speed of 200r / min. After 6...

Embodiment 2

[0040] A method for preparing high-purity vanadium pentoxide by precipitating vanadium from sodium vanadate solution, comprising the following steps:

[0041] 1) Sodium vanadate solution 50mL, adjust the pH of the solution to 2.8 with sulfuric acid, add 0.1g of anionic polyacrylamide CPAM, stir and react at room temperature at a stirring speed of 200r / min for 50min, let stand for 14h, suction filter, and wash with deionized water Filter residue 2 to 3 times, the measured desiliconization rate is 87.67%, vanadium loss rate is 0.29%, and the filtrate is called vanadium qualified liquid;

[0042] 2) At room temperature, add the qualified vanadium solution dropwise to 1 mol / L sulfuric acid solution while stirring until the pH of the mixed solution is 2.0, then stir and react the mixed solution at T=90°C with a stirring speed of 200r / min for 90min , the solution was naturally cooled to room temperature, the solid and liquid were separated by suction filtration, and the solid was co...

Embodiment 3

[0046] A method for preparing high-purity vanadium pentoxide by precipitating vanadium from sodium vanadate solution, comprising the following steps:

[0047] 1) Sodium vanadate solution 50mL, adjust the pH of the solution to 3.0 with sulfuric acid, add 0.35g of anionic polyacrylamide CPAM, stir and react at room temperature at a stirring speed of 200r / min for 60min, let stand for 14h, suction filter, and use a little deionized water Wash the filter residue 2 to 3 times, the measured desiliconization rate is 88.66%, the vanadium loss rate is 0.14%, and the filtrate is called vanadium qualified liquid;

[0048] 2) At room temperature, add the qualified vanadium solution dropwise to 1mol / L sulfuric acid solution while stirring, until the pH of the mixed solution is 2.4, and stir the mixed solution at T=90°C for 90min at a stirring speed of 200r / min , the solution was naturally cooled to room temperature, the solid and liquid were separated by suction filtration, and the solid wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com