Ultrahigh-strength steel quick-setting concrete polyurea composite material as well as preparation method and application thereof

A composite material and ultra-high-strength steel technology, used in buildings and building structures, etc., can solve the problems of difficult to achieve compaction of blast-proof wall concrete, vibration noise pollution, low early strength, etc., to increase compactness and reduce hydration heat. , the effect of enhancing strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

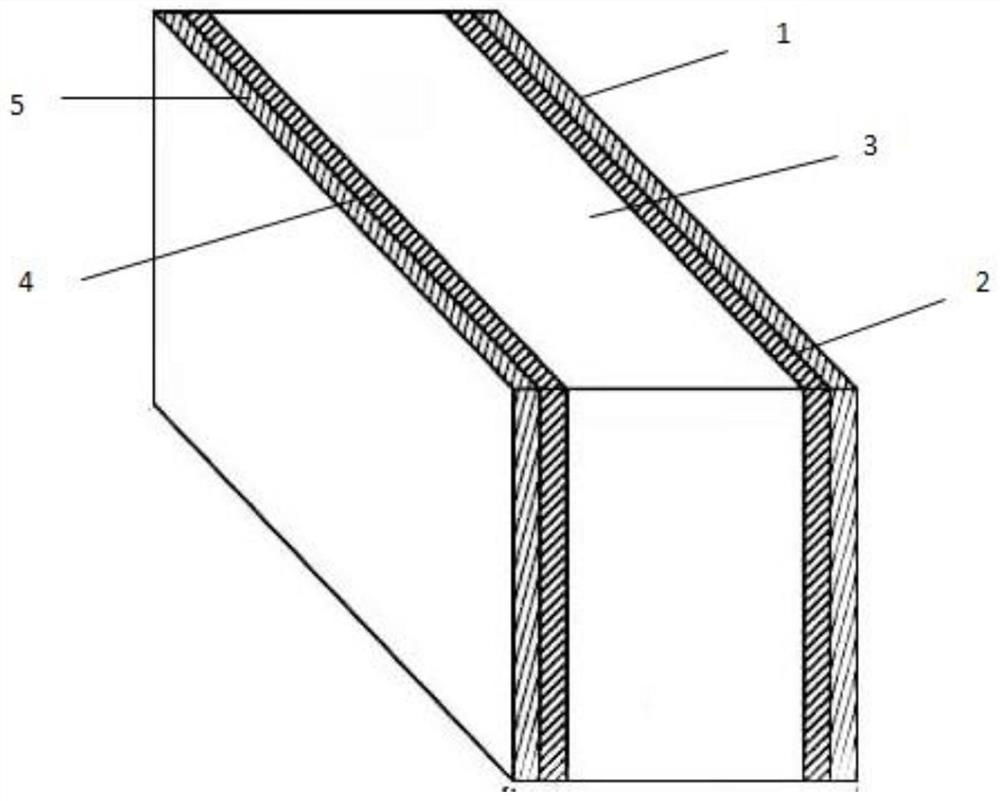

[0032] Such as figure 1 Shown: a high-strength steel concrete polyurea coating composite material, the ultra-high-strength steel quick-setting concrete polyurea composite material is a cuboid block composite material, divided into 5 layers, the first layer and the fifth layer are lead alloy sheets , the second and fourth layers are explosion-proof steel plates, and the third layer is a high-strength self-leveling concrete layer, that is, the two sides of the high-strength self-leveling concrete layer are respectively compounded with explosion-proof steel plates, and the outer sides of the two explosion-proof steel plates are respectively compounded with lead Alloy sheet; the ultra-high-strength steel quick-setting concrete polyurea composite material includes six faces, and each face is coated with a polyurea coating of 6mm; the length of the ultra-high-strength steel quick-setting concrete polyurea composite material is 1800mm, and the width is 1000mm and a height of 800mm; t...

Embodiment 2

[0036] Such as figure 1Shown: a high-strength steel concrete polyurea coating composite material, the ultra-high-strength steel quick-setting concrete polyurea composite material is a cuboid block composite material, divided into 5 layers, the first layer and the fifth layer are lead alloy sheets , the second and fourth layers are explosion-proof steel plates, and the third layer is a high-strength self-leveling concrete layer, that is, the two sides of the high-strength self-leveling concrete layer are respectively compounded with explosion-proof steel plates, and the outer sides of the two explosion-proof steel plates are respectively compounded with lead Alloy sheet; the ultra-high-strength steel quick-setting concrete polyurea composite material includes six faces, and each face is coated with 7mm polyurea coating; the length of the ultra-high-strength steel quick-setting concrete polyurea composite material is 2000mm, and the width is 300mm and a height of 1000mm; the thi...

Embodiment 3

[0041] like figure 1 Shown: a high-strength steel concrete polyurea coating composite material, the ultra-high-strength steel quick-setting concrete polyurea composite material is a cuboid block composite material, divided into 5 layers, the first layer and the fifth layer are lead alloy sheets , the second and fourth layers are explosion-proof steel plates, and the third layer is a high-strength self-leveling concrete layer, that is, the two sides of the high-strength self-leveling concrete layer are respectively compounded with explosion-proof steel plates, and the outer sides of the two explosion-proof steel plates are respectively compounded with lead Alloy sheet; the ultra-high-strength steel quick-setting concrete polyurea composite material includes six faces, and each face is coated with 8mm polyurea coating; the length of the ultra-high-strength steel quick-setting concrete polyurea composite material is 2200mm, and the width is 800mm and a height of 1200mm; the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com