Method and device for producing calcium magnesium phosphate fertilizer from magnesium-removed clear liquid

A technology of calcium magnesium phosphate fertilizer and magnesium clear liquid, which is applied in fertilization devices, phosphate fertilizers, chemical instruments and methods, etc., can solve the problems of waste of magnesium resources and high magnesium content in return water, so as to improve the utilization rate, reduce the magnesium content, and increase the income. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

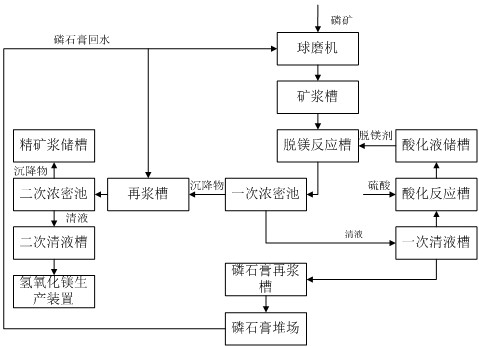

Image

Examples

Embodiment 1

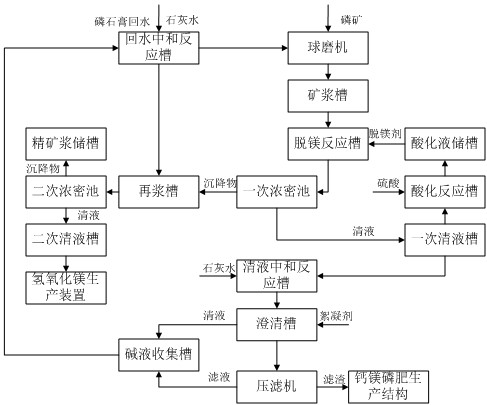

[0026] see figure 2 , Example 1 provides a device for producing calcium-magnesium phosphate fertilizers from magnesium-removing clear liquid, including a clear liquid tank (used to store a clear liquid, which is divided into two outputs, mainly to meet the dosage requirements of the magnesium-removing agent, and the remaining for the production of calcium magnesium phosphate fertilizer), acidification reaction tank (for the preparation of magnesium removal agent), acidification liquid storage tank (for storage of magnesium removal agent), backwater neutralization reaction tank (for the return water of phosphogypsum and quicklime or lime water react, adjust the pH to 6-7), clear liquid neutralization reaction tank (used to react the primary clear liquid with quicklime or lime water, adjust the pH to 10-11), clarification tank (conventional structure for sedimentation), Filter press (conventional structure, used for pressure filtration), calcium magnesium phosphate fertilizer p...

Embodiment 2

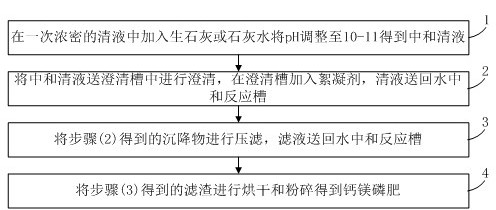

[0034] see Figure 2-3 , embodiment 2 provides a kind of method for producing calcium magnesium phosphate fertilizer from demagnesizing clear liquid, can adopt the disclosed device of embodiment 1, and this method comprises:

[0035] (1) Add quicklime or lime water (preferably lime water) to a thick clear liquid to adjust the pH to 10-11 (magnesium basically settles out) to obtain a neutral clear liquid.

[0036] (2) Send the neutralized clear liquid obtained in step (1) to the clarification tank for clarification, add a flocculant with a weight of 0.1-0.4% of the neutralized clear liquid in the clarifier tank, and the clarification time is 1-2 hours, and the clear liquid is sent back to the water And reaction tank (neutralization reaction with phosphogypsum backwater).

[0037](3) Press filter the sediment obtained in step (2), and send the filtrate back to the water neutralization reaction tank (neutralization reaction with phosphogypsum backwater).

[0038] (4) drying and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com