Production process for simultaneously producing ginkgolide, ginkgo flavone, ginkgo polysaccharide and shikimic acid

A production process, the technology of ginkgo flavonoids, applied in the production process of ginkgo polysaccharides and shikimic acid, ginkgo flavonoids, and ginkgolides at the same time, can solve the problems of increasing the production process, high cost of raw materials, large amount of organic solvents, etc., to achieve The effect of reducing the evaporation of acetic acid, improving product quality and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

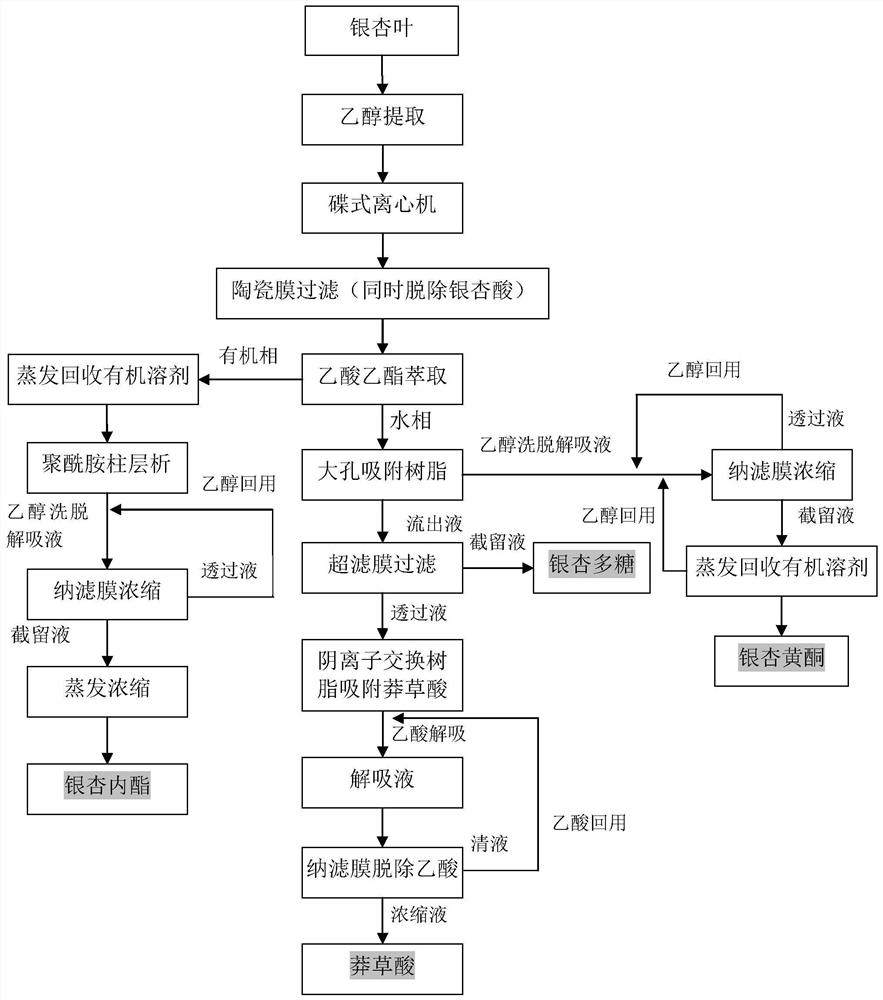

[0110] Embodiment 1: according to such as figure 1 The flowchart shown for the extraction of Ginkgo polysaccharides and shikimic acid:

[0111] (1) Ginkgo biloba is crushed to 20 meshes, leached with 60% ethanol solution at 50-80° C., and extracted 6 times to obtain the crude extract of ginkgo biloba;

[0112] (2) The crude extract obtained in step (1) is evaporated and concentrated, and after being concentrated 6 times, the Ginkgo biloba extract concentrate is obtained, and ethanol is recovered simultaneously;

[0113] (3) centrifuging the ginkgo leaf extract concentrate obtained in step (2) at 6000rpm / min disc centrifuge for 10min to obtain the ginkgo extract centrate;

[0114] (4) After the ginkgo extract centrifugate obtained in step (3) is filtered and clarified through the ceramic ultrafiltration membrane after activation modification, and impurities are removed, the ceramic membrane filtrate is obtained, wherein the content of ginkgo polysaccharide is 0.47%, and the co...

Embodiment 2

[0128] Embodiment 2: according to as figure 1 The flowchart shown for the extraction of Ginkgo polysaccharides and shikimic acid:

[0129] (1) Ginkgo biloba is crushed to 20 meshes, leached with 60% ethanol solution at 50-80° C., and extracted 6 times to obtain the crude extract of ginkgo biloba;

[0130] (2) The crude extract obtained in step (1) is evaporated and concentrated, and after being concentrated 6 times, the Ginkgo biloba extract concentrate is obtained, and ethanol is recovered simultaneously;

[0131] (3) centrifuging the ginkgo leaf extract concentrate obtained in step (2) at 6000rpm / min disc centrifuge for 10min to obtain the ginkgo extract centrate;

[0132] (4) After the ginkgo extract centrifugate obtained in step (3) is filtered and clarified through the ceramic ultrafiltration membrane after activation and modification, and impurities are removed, the ceramic membrane filtrate is obtained, wherein the content of ginkgo polysaccharide is 0.48%, and the conte...

Embodiment 3

[0146] Embodiment 3: according to such as figure 1 The flowchart shown for the extraction of Ginkgo polysaccharides and shikimic acid:

[0147] (1) Ginkgo biloba is crushed to 20 meshes, leached with 60% ethanol solution at 50-80° C., and extracted 6 times to obtain the crude extract of ginkgo biloba;

[0148] (2) The crude extract obtained in step (1) is evaporated and concentrated, and after being concentrated 6 times, the Ginkgo biloba extract concentrate is obtained, and ethanol is recovered simultaneously;

[0149] (3) centrifuging the ginkgo leaf extract concentrate obtained in step (2) at 6000rpm / min disc centrifuge for 10min to obtain the ginkgo extract centrate;

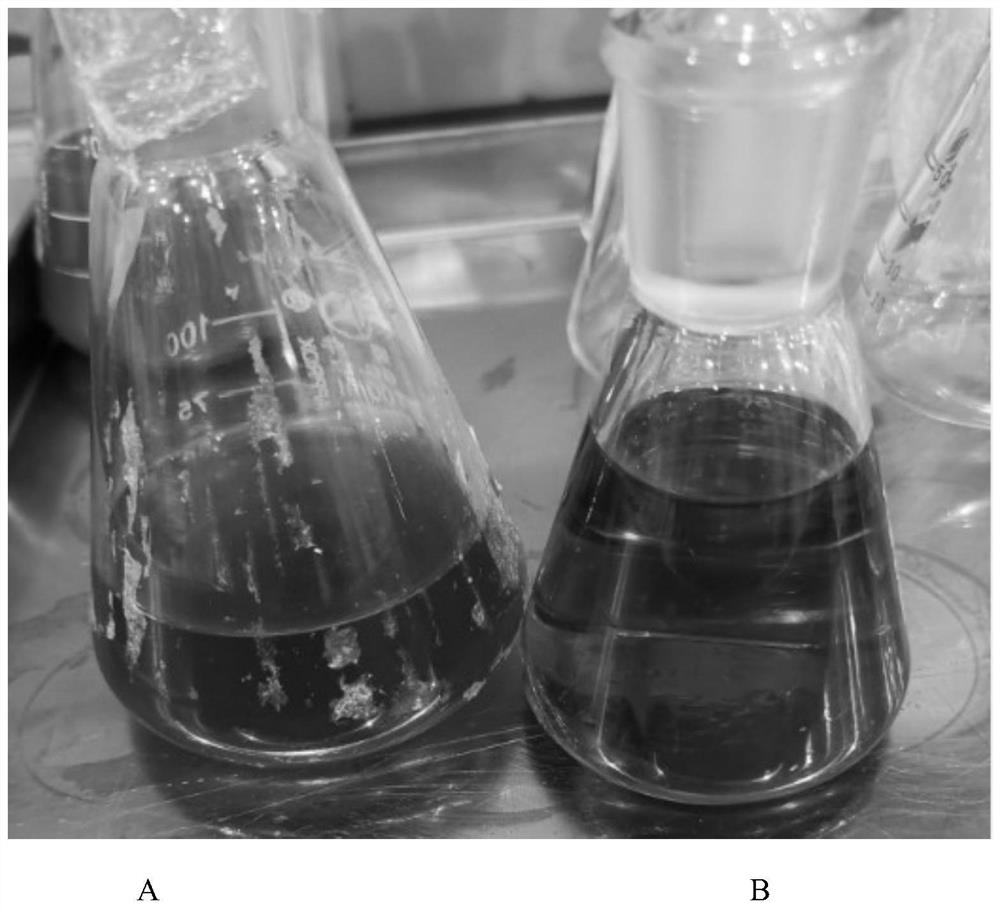

[0150] (4) after the ginkgo extract centrifugate obtained by step (3) is filtered and clarified through the ceramic ultrafiltration membrane after the activation modification, after impurity removal, obtain such as figure 2 The shown ceramic membrane filtrate, wherein, the content of ginkgo polysaccharide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com