Thallus culture equipment and method

A technology for culturing equipment and cells, applied in biochemical equipment and methods, methods for sampling biological materials, biochemical instruments, etc., can solve problems such as unfavorable cell separation, complex structure, etc., to improve convenience, production efficiency, and simplification. Equipment structure, the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

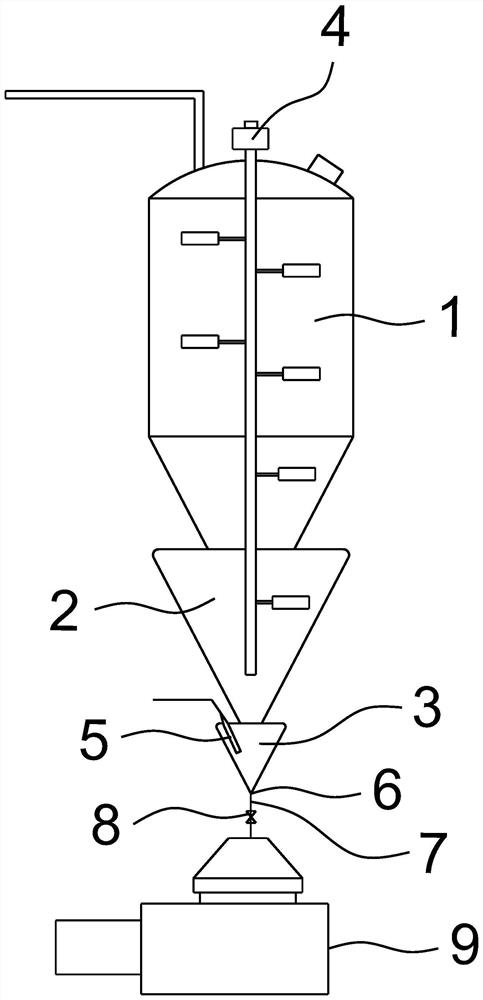

[0038] Utilize the thalline culture equipment and the thalline culture equipment method provided by the present invention to continuously cultivate yeast;

[0039] In this example, the fermenter used has a total volume of about 650 L, the cylindrical body of the first chamber 1 has a height of 75 cm and a diameter of 80 cm, and the height of the inverted conical bottom of the first chamber 1 is 20 cm , the lower end diameter is 35cm; the height of the second chamber 2 of inverted conical shape is 100cm, and the upper and lower end diameters are respectively 80cm and 10cm; the height of the third chamber 3 of inverted conical shape is 53cm, and the diameter of the upper end is 42cm; the first The respective volumes of the chamber 1, the second chamber 2 and the third chamber 3 respectively account for about 66%, 30% and 4% of the total volume of the fermenter.

[0040] During cultivation, first pump 500L of yeast wort culture medium into the fermenter, and sterilize it, then in...

Embodiment 2

[0046] Utilize the thalline culture equipment and the thalline culture equipment method provided by the present invention to continuously cultivate Lactobacillus plantarum;

[0047] In this embodiment, the total volume of the fermentor used is about 2500L, the height of the cylindrical body of the first chamber 1 is 1m, and the diameter is 1.36cm, and the height of the inverted conical bottom of the first chamber 1 is 30cm, the lower end diameter is 43cm; the height of the second inverted conical chamber 2 is 107cm, the upper and lower end diameters are respectively 136cm and 36.5cm; the height of the third inverted conical chamber 3 is 57cm, and the upper end diameter is 57cm; The respective volumes of the first chamber 1 , the second chamber 2 and the third chamber 3 respectively account for about 68%, 30% and 2% of the total volume of the fermenter.

[0048] When cultivating, first pump 2000LMRS medium into the fermenter and sterilize it, then insert the seed liquid of Lact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com