Liquid oil-in-water composition

A technology for liquid water and composition, applied in the field of liquid oil-in-water composition, can solve the problems of lack of viscosity stability, viscosity over time, instability, etc., achieve excellent emulsion stability, maintain effect, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0118] Reference Example 1: Preparation of liposome-containing lotion

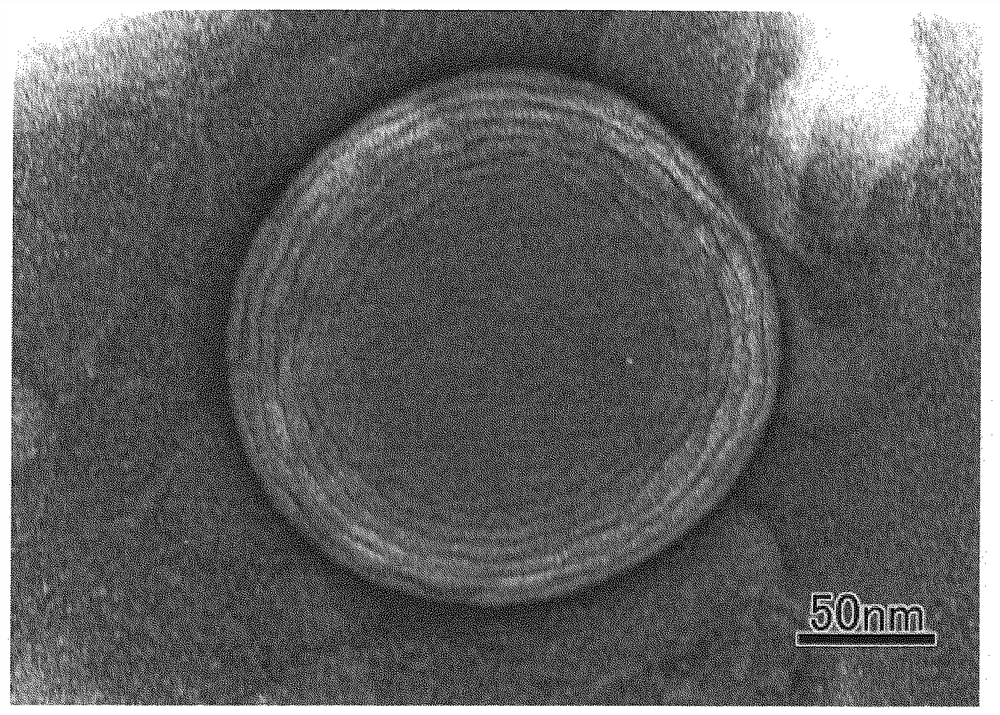

[0119] A lotion having the composition shown below was prepared by the following preparation method. The obtained lotion was observed with an electron microscope. Electron micrographs are shown in Figure 4 middle.

[0120] Reference example 1: lotion

[0121] (Element) (%)

[0122] 1. Phospholipids 1.0

[0123] 2. Xanthan gum 0.1

[0124] 3. Carboxyvinyl polymer 0.05

[0125]4. 1,3-Butanediol 20.0

[0126] 5. Glycerin 4.5

[0127] 6. Sodium hydroxide 0.02

[0128] 7. Parabens 0.1

[0129] 8. Spices trace

[0130] 9. Purified water balance.

[0131] (Preparation)

[0132] A: liposome part of No. 1, 8 and 9

[0133] B: Mix all remaining ingredients

[0134] C: Mix A and B to obtain lotion.

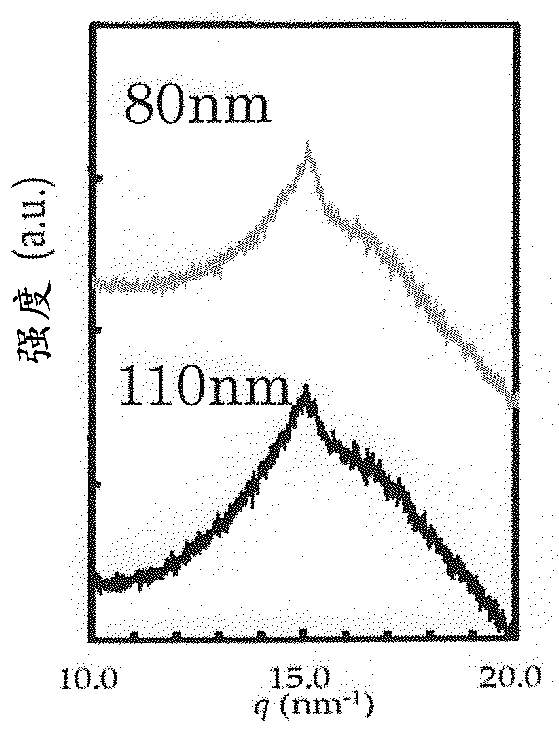

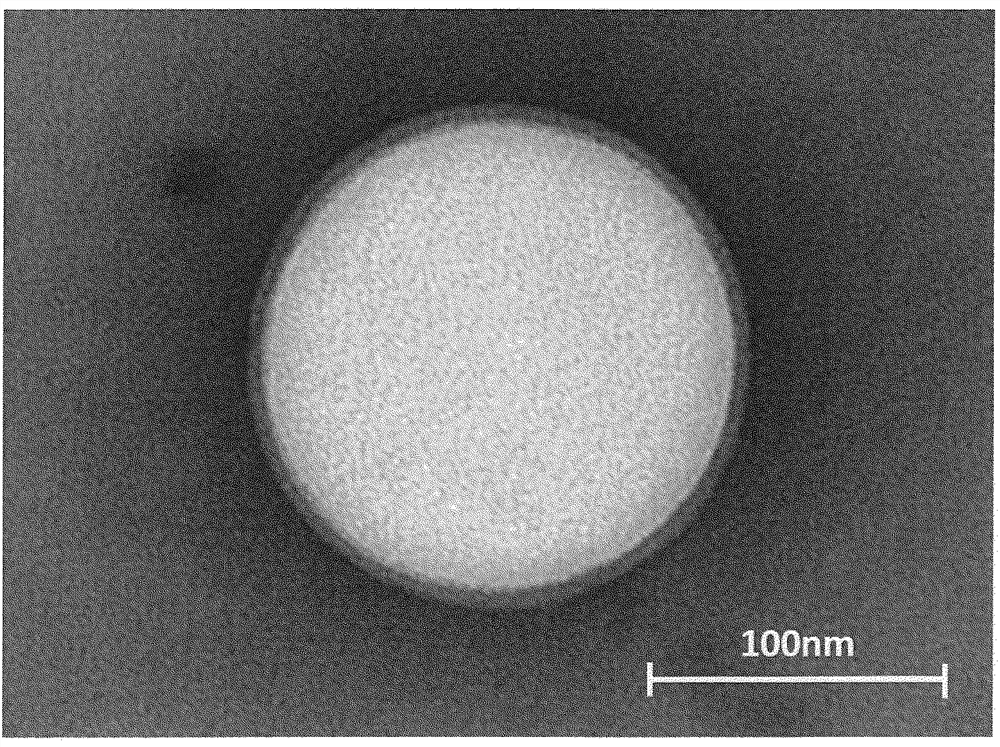

[0135] image 3 The emulsified droplet having the α-gel film structure of the present invention has an oil phase in the interior, in contrast to this, Figure 4 Liposomes in do not have an oil phase in...

Embodiment 1~14 and comparative example 1~12

[0138] Lotions having the compositions shown in Tables 3 to 6 below were prepared by the following preparation method. For the obtained lotion, the viscosity and emulsification state were evaluated immediately after preparation and after storage at 50° C. for one month according to the following measurement methods and judgment criteria. In addition, the presence of the α-gel film structure covering the emulsified droplet was evaluated by the following method. The results are combined and shown in Tables 3-6. In addition, the numerical value in the composition of Tables 3-6 means %.

[0139] [table 3]

[0140]

[0141] *1 Nikkol SMT (manufactured by Nikko Chemicals Co., Ltd.)

[0142] *2 Amisoft HA-P (manufactured by Kaei Kogyo Co., Ltd.)

[0143] *3 Nikkol DDP-8 (manufactured by Nikko Chemicals Co., Ltd.).

[0144] [Table 4]

[0145]

[0146] [table 5]

[0147]

[0148] [Table 6]

[0149]

[0150]

Embodiment 1、7、8、10

[0152] A: Heat and mix numbers 1~15 evenly to dissolve

[0153] B: Heat and mix numbers 16~19 evenly to dissolve

[0154] C: Add A to B for emulsification and mixing

[0155] D: Cool C, and perform high-pressure dispersion treatment (pressure 200 MPa) twice with a micro-fluidizer to obtain lotion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com